Method for preparing catalyst for RCO-SCR (Regenerative Catalytic Oxidation-Selective Catalytic Reduction) integrated reaction

A monolithic catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, combustion methods, etc., can solve the problems of ammonia resource consumption, save ammonia resources, improve catalytic activity, and increase effective catalytic area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

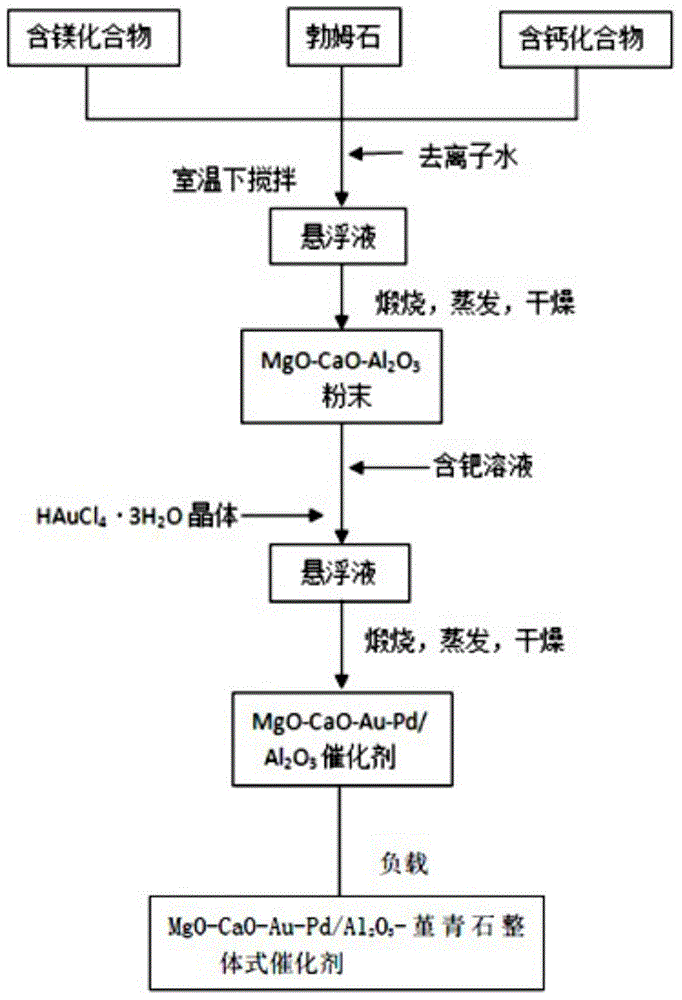

Embodiment 1

[0042] (1) Take 11g Mg(NO 3 ) 2 ·6H 2 O with 4.5g CaCl 2 Dissolve in 100ml deionized water, add a certain amount of boehmite (Mg, Ca and Al 2 o 3 The mass ratio of the carrier is 5:8:100);

[0043] (2) The obtained suspension was evaporated to dryness at 100°C, dried at 100°C for 16 hours, and calcined at 500°C for 6 hours to obtain 5% MgO-8% CaO / Al 2 o 3 powder;

[0044] (3) Take 12.2g of the above powder and 0.04g HAuCl4 3H 2 O crystals dispersed in 100ml PdCl 2 solution (0.012mol / L), fully stirred and mixed to obtain a suspension;

[0045] (4) After the above suspension was evaporated to dryness at 120°C, it was dried at 120°C for 8 hours, and then calcined at 700°C for 4 hours to obtain 5%MgO-8%CaO-0.2%Au-1.2%Pd / Al 2 o 3 powdered catalyst;

[0046] (5) Place the obtained powder catalyst in an appropriate amount of deionized water, stir, add an appropriate amount of carboxymethyl cellulose thickener to form a thick liquid, and load the above thick liquid on the ...

Embodiment 2

[0052] (1) Take 2.5g MgCl 2 ·6H 2 O with 10.8g Ca(NO 3 ) 2 4H 2 O was dissolved in 100ml deionized water, and a certain amount of boehmite (Mg, Ca and Al 2 o 3 The mass ratio of the carrier is 2:12:100);

[0053] (2) The obtained suspension was evaporated to dryness at 80°C, dried at 80°C for 15 hours, and calcined at 400°C for 9 hours to obtain 2% MgO-12% CaO / Al 2 o 3 powder;

[0054] (3) Take 9.2g of the above powder and 0.06g of HAuCl4 3H 2 O crystals dispersed in 100ml Pd(NO 3 ) 2 solution (0.012mol / L), fully stirred and mixed to obtain a suspension;

[0055] (4) After the above suspension was evaporated to dryness at 90°C, dried at 90°C for 16 hours, and then calcined at 500°C for 9 hours to obtain 2%MgO-12%CaO-0.4%Au-1.6%Pd / Al 2 o 3 powdered catalyst;

[0056] (5) Place the obtained powder catalyst in an appropriate amount of deionized water, stir, add an appropriate amount of sodium alginate thickener to form a thick liquid, and load the above thick liquid...

Embodiment 3

[0061] (1) Take 25g MgSO 4 with 4.2g CaCl 2 Dissolve in 100ml deionized water, add a certain amount of boehmite (Mg, Ca and Al 2 o 3 The mass ratio of the carrier is 8:5:100);

[0062] (2) After the obtained suspension was evaporated to dryness at 110°C, it was dried at 110°C for 14 hours, and then calcined at 600°C for 4 hours to obtain 8% MgO-5% CaO / Al 2 o 3 powder;

[0063] (3) Take 18.4g of the above powder and 0.24g HAuCl4 3H 2 O crystals dispersed in 100ml Na 2 PdCl 4 solution (0.0028mol / L), fully stirred and mixed to obtain a suspension;

[0064] (4) After the above suspension was evaporated to dryness at 115°C, it was dried at 115°C for 12 hours, and then calcined at 400°C for 6 hours to obtain 8%MgO-5%CaO-0.8%Au-0.2%Pd / Al 2 o 3 powdered catalyst;

[0065] (5) Place the obtained powder catalyst in an appropriate amount of deionized water, stir, add an appropriate amount of diatomaceous earth thickener to form a thick liquid; load the above thick liquid on cord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com