Method for recovering ammonia from ammonia waste water

A technology for recovering ammonia and waste water, applied in the field of ammonia recovery, can solve the problems of environmental pollution, difficulty in removing ammonia, waste of ammonia resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

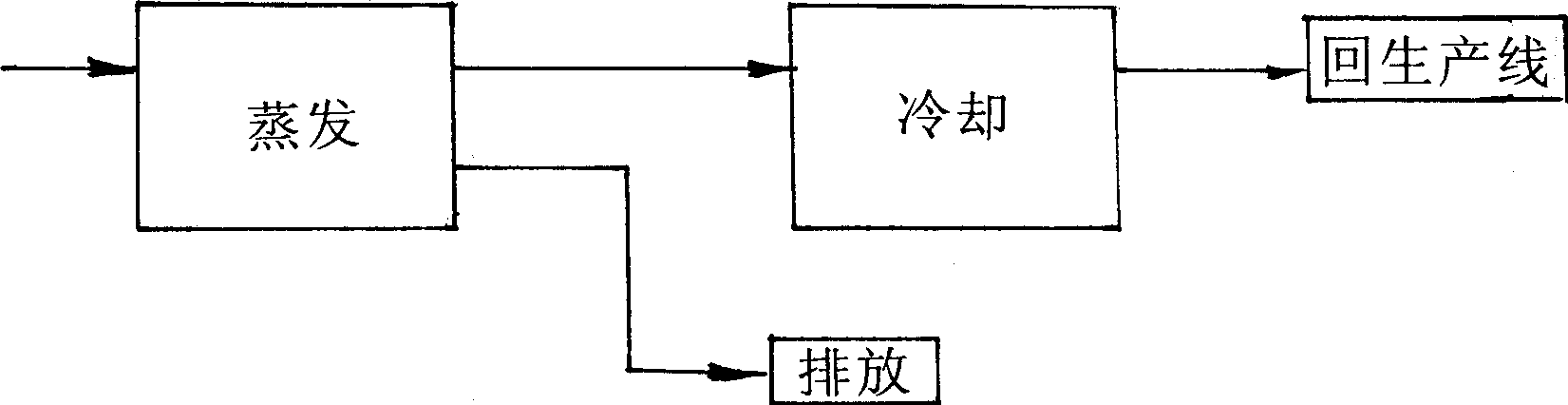

[0005] Ammonia recovery method of the present invention has following steps:

[0006] (1) The ammonia-containing wastewater is sent to a centrifugal separator to separate the water-insoluble alkali in the wastewater to obtain ammonia wastewater without solid alkali.

[0007] (2) above-mentioned ammonia-containing waste water is sent to carry out fractional distillation and cooling to obtain pure ammoniacal liquor (18%-25%) in the bubble-cap type rectifying tower, returns to production line and reuses; The ammonia content in the waste water after rectification exceeds Environmental protection standard, can be discharged directly. Distillation process parameters: vapor pressure 0.1-0.5Mpa, waste water flow 2-5M 3 / h, the liquid level in the tower is 1000-2000mm, and the wastewater temperature is 90-110°C. The bubble-cap type rectification column used is a patented product, and the patent number is ZL922327009.

[0008] Wastewater impurity content before treatment (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com