Pretreatment device of organic waste gas and use method of pretreatment device

A pretreatment device and organic waste gas technology, applied in the direction of auxiliary pretreatment, separation methods, chemical instruments and methods, etc., can solve the problems of odor pre-wetting treatment, etc., and achieve the effects of enhancing stability, improving work efficiency, and saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

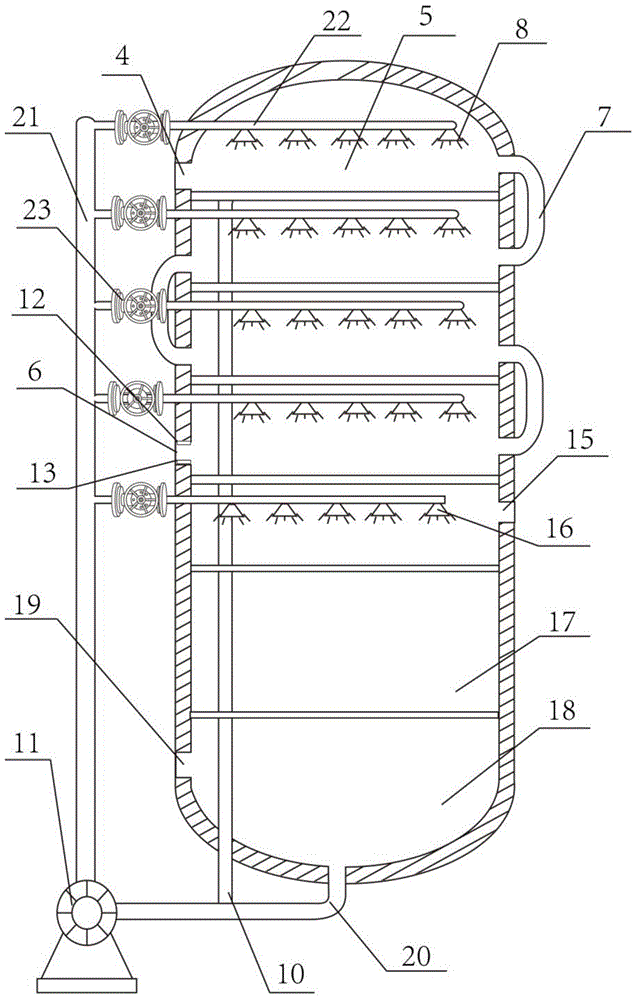

[0038] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0039] As shown in the figure, a pretreatment device for organic waste gas includes a cooling and deodorizing tower 1 and a three-stage dedusting chamber 3. The cooling and deodorizing tower 1 includes a primary cooling chamber and a secondary deodorizing chamber. The smelly tower 1 is provided with supporting feet 2,

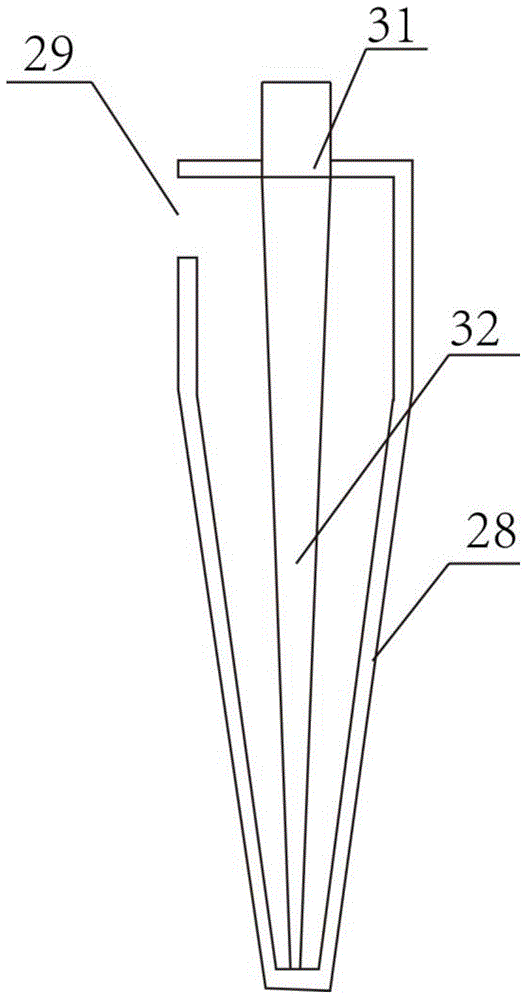

[0040] The first-level cooling chamber includes a hot gas inlet 4, several layers of spray chambers 5 and moisture outlets 6, and a ventilation pipe 7 is connected between two adjacent layers of spray chambers 5, and a cooling chamber is arranged in the spray chamber 5. Spray head 8, the bottom of spray chamber 5 is provided with water collecting port 9, and described water collecting port 9 is connected with water collecting pipe 10, and described water collecting pipe 10 is connected with the water inlet of circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com