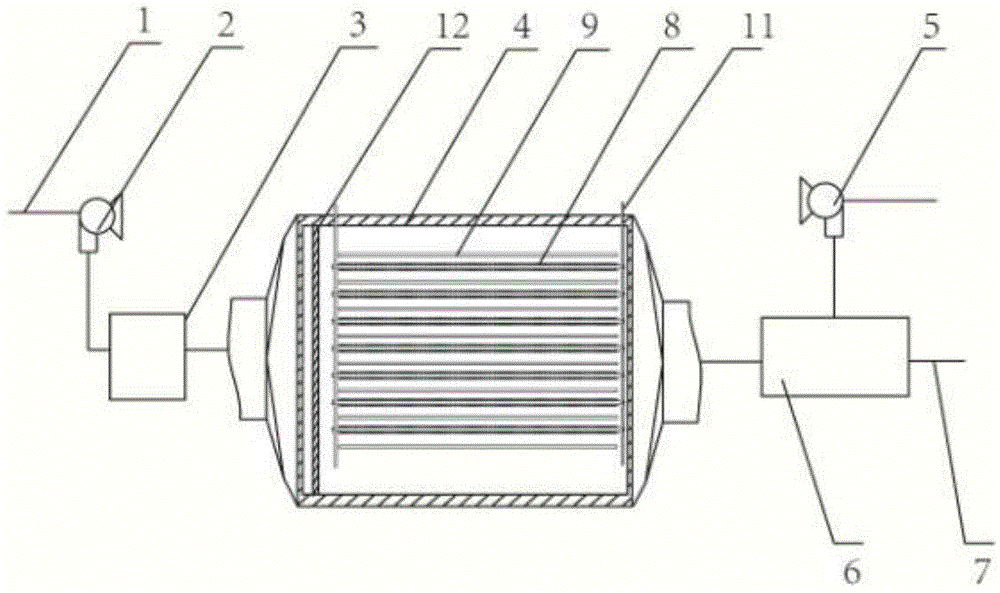

Plasma waste gas treatment equipment and treatment process

A technology of waste gas treatment and plasma, which is applied in the direction of separation method, dispersed particle separation, chemical instruments and methods, etc., can solve the problems that are easy to cause danger and affect the discharge effect, and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

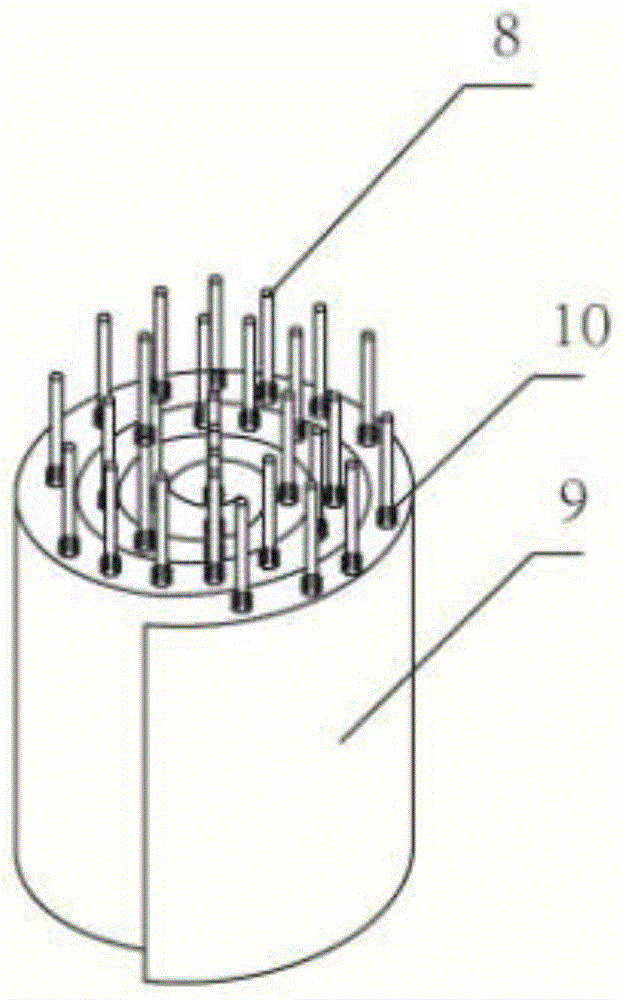

[0037] The components of the plasma exhaust gas treatment equipment are connected, the exhaust gas enters from the air inlet pipe, and is introduced into the dust filter through the induced draft fan. The filtered exhaust gas enters the plasma processor, and after the decomposition and purification of the plasma, it is discharged into the ozone processor. The air blower blows into the ozone processor and mixes with the purified gas. The temperature of the ozone processor is 60°C. The ozone generated by the plasma processor is removed and discharged through the exhaust pipe. The exhaust gas concentration is 1g / m3 and the exhaust gas flow rate is 150L. / min, the exhaust gas removal rate after the final purification is 98%.

Embodiment 2

[0039] The components of the plasma exhaust gas treatment equipment are connected, the exhaust gas enters from the air inlet pipe, and is introduced into the dust filter through the induced draft fan. The filtered exhaust gas enters the plasma processor, and after the decomposition and purification of the plasma, it is discharged into the ozone processor. The air blower blows into the ozone processor and mixes with the purified gas. The temperature of the ozone processor is 60°C. The ozone generated by the plasma processor is removed and discharged through the exhaust pipe. The concentration of the exhaust gas is 2g / m3 and the flow rate of the exhaust gas is 150L. / min, the exhaust gas removal rate after the final purification is 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com