Audio frequency induction vacuum cleaner controller

A controller and vacuum cleaner technology, applied in vacuum cleaners, applications, cleaning equipment, etc., can solve problems such as motor damage, blockage of elbows and hose joints, and reduced suction power of vacuum cleaners, so as to ensure safe use, cleanliness, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

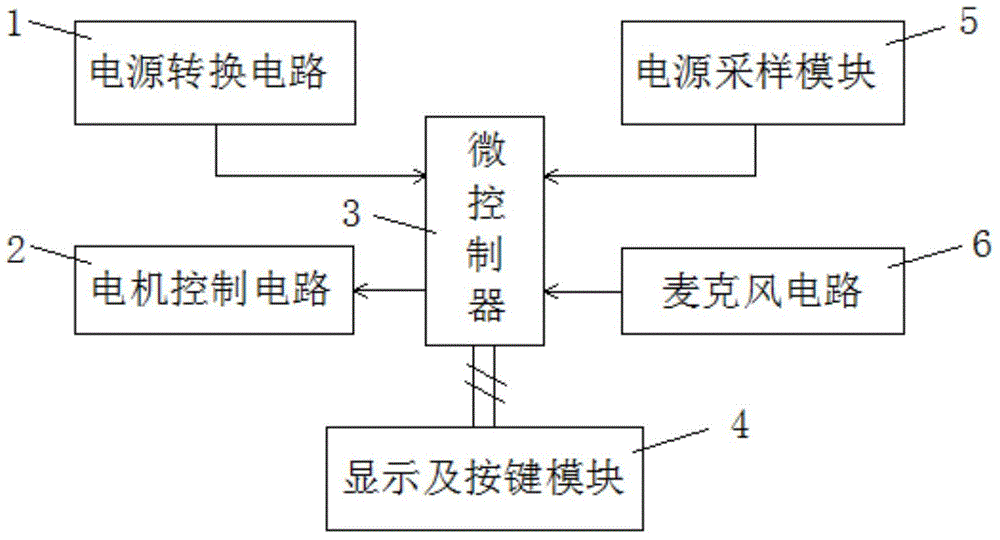

[0035] in figure 1 In the overall circuit structure diagram, the power conversion circuit provides a stable output voltage for the microcontroller to work after power conversion; at the same time, the power sampling module collects the information of the connected power source through the A / D conversion and software algorithm in the microcontroller Calculate various electrical parameters connected to the power supply, including but not limited to voltage, period, current phase, and zero-crossing time of the power supply. These electrical parameters are provided for subsequent software control and calculation use; the microphone collects the motor suction port and dust collection The audio information between the bags is processed through the A / D conversion and software code in the microcontroller to determine whether the vacuum cleaner is blocked and the dust bag is full, and the result is reflected to the display and LED on the button module The lamp is displayed; the setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com