Method and control device for operating drive train

A power transmission system and control device technology, applied in the direction of power devices, control devices, air pressure power devices, etc., can solve the problems of operating room safety, insufficient stability, lack of control devices, large vibration, etc., to achieve strong intelligence , Improve comfort and reduce vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

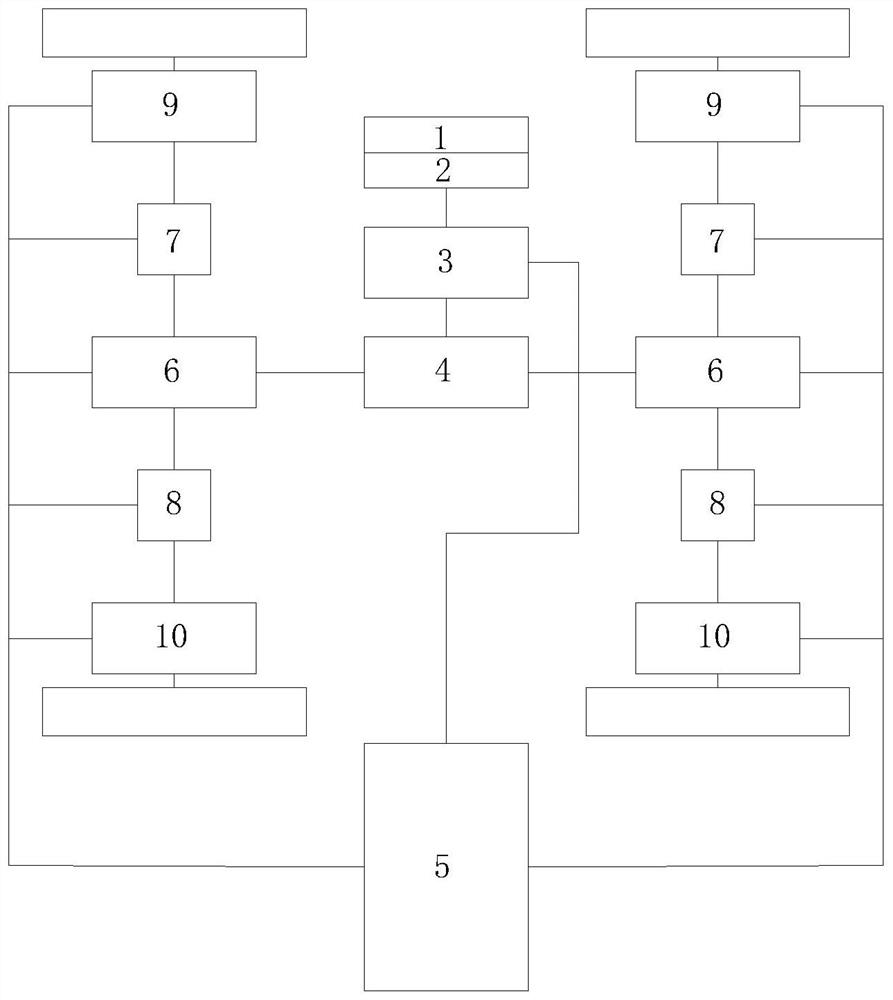

[0019] As shown in FIG. 1, the present invention proposes a method for operating a powertrain comprising a drive train

[0022] Further, the differential one 7 and the differential two 8 are slip differentials.

[0023] Further, the power train also includes a locking piece; the locking piece is arranged on the first side drive shaft and the second side drive shaft.

Embodiment 2

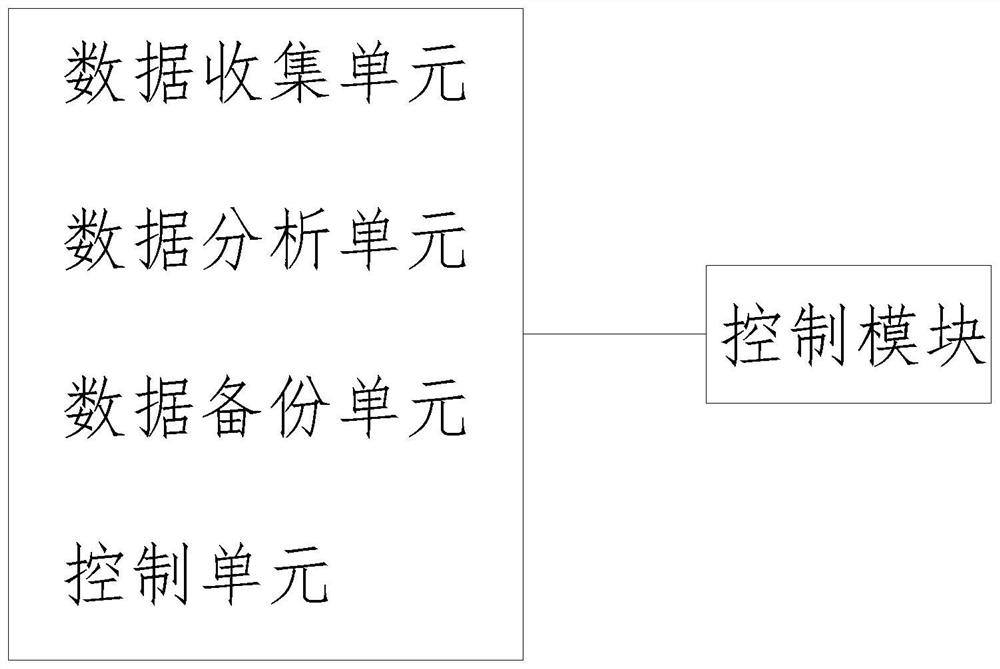

[0028] As shown in FIG. 2, the present invention further provides a control device for operating a powertrain including a control module

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com