Cement proportioning method for building construction

A technology of building construction and cement, which is applied in the field of cement proportioning for building construction, can solve problems affecting the safety effect of buildings, and achieve the effect of ensuring strength, quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

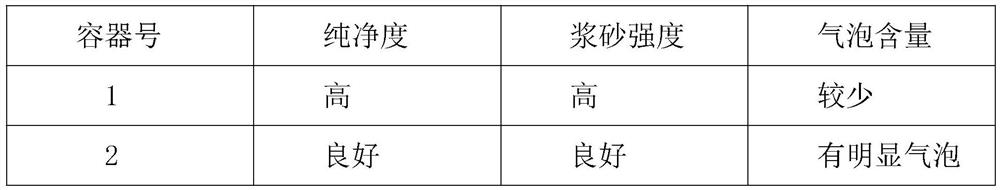

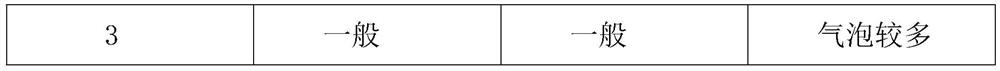

Examples

Embodiment 1

[0020] The invention provides a technical solution: a cement proportioning method for building construction, comprising the following steps:

[0021] S1. Raw materials preparation: first prepare raw materials such as cement, fine aggregate and water in proportion, and ensure that the ratio is 1:3:0.65, so that the density of the mixed cement mortar is kept at about 2000Kg / m3~2500Kg / m3.

[0022] S2. Raw material screening: First, pass the cement and fine aggregate in the raw material through a 5-10 mesh screen and a 20-30 mesh screen, and set a receiving hopper under the two screens, and at the same time, pass through the screen that has not passed through the screen. The garbage, such as: plastic chips, grass roots, stones, etc., is collected and centralized harmless treatment with professional collection tools, and then the fine aggregate is passed through a 15-mesh to 20-mesh sieve for the second time to ensure its internal waste. Large particles are removed cleanly.

[002...

Embodiment 2

[0029] The specific difference from Example 1 is that in the raw material screening process, only 20-30 mesh sieves are used to carry out a sieve screening operation process for the fine aggregate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com