Safety plant for a cable stretching machine, corresponding method and stretching machine using said plant

A stretching machine and equipment technology, applied in the direction of overhead line/cable equipment, mechanical equipment, brake actuators, etc., can solve problems such as damage, loss of cable tension, uncoordinated stop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

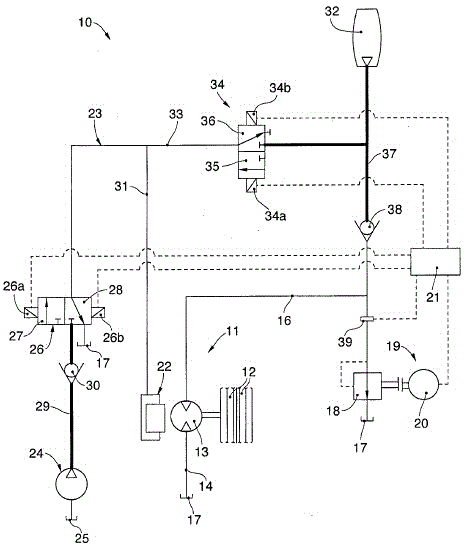

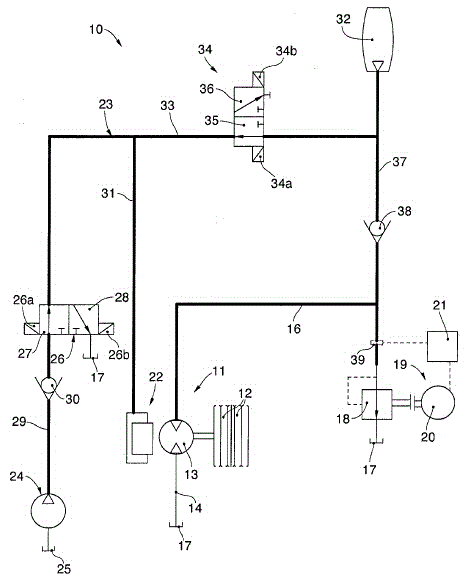

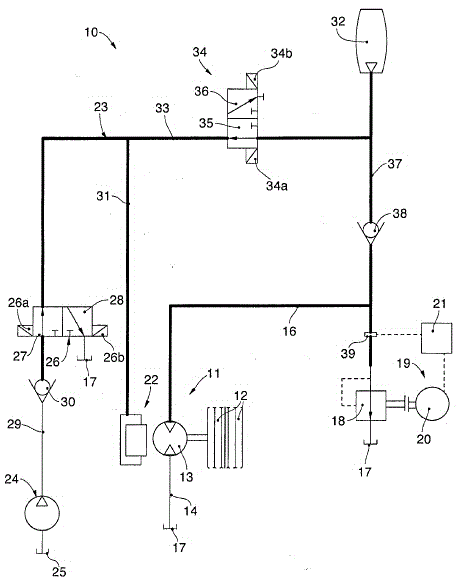

[0043] The invention relates to a safety device 10 for a stretching machine 11 of a cable ( figure 1 ), this cable is wound on the corresponding capstan, in this case a pair of capstans.

[0044] The stretching machine 11 is of the type having a braking function and configured to control the tension with which the cable is unwound from the pair of winches.

[0045] The stretching machine 11 comprises at least one hydraulic motor 13 configured to be drawn in rotation by the pair of winches 12, operating as a hydraulic pump to keep the cable under tension during normal stretching operations.

[0046] The hydraulic motor 13 is connected to a hydraulic circuit comprising a suction branch 14 through which working fluid is drawn from a tank 17 , and a delivery branch 16 or pipe connected to a maximum pressure valve 18 . The maximum pressure valve 18 is configured to maintain a substantially constant pressure in the delivery branch 16 and subsequently in the hydraulic motor 13 even ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com