A pneumatic tablet pressing tool for single insert

A technology of inserting and pressing tablets, which is applied in the direction of assembling printed circuits, electrical components, and printed circuits with electrical components, can solve the problems of improving the quality of pressing tablets, increasing the labor burden of operators, and unfavorable problems, so as to improve the quality of pressing tablets, The effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

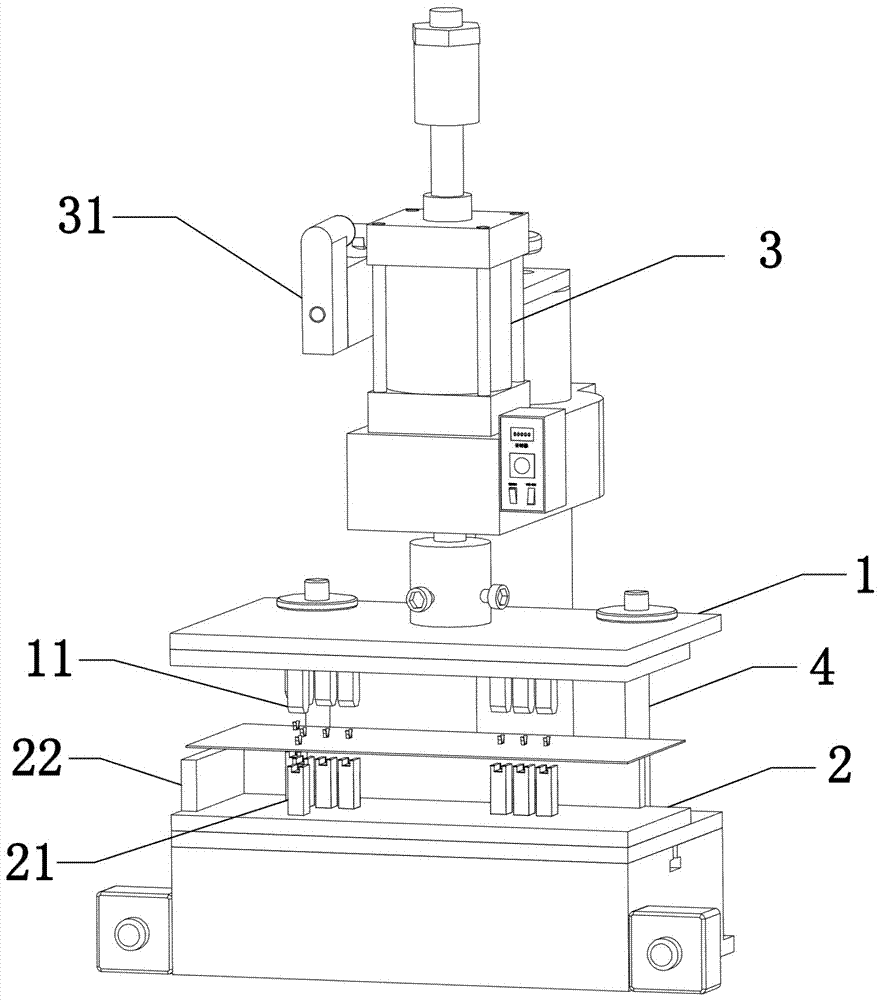

[0015] See attached Figure 1-2 As shown, the pneumatic tablet pressing tool for single insert in this embodiment includes an upper mold 1, a lower mold 2, and a driving cylinder 3 for driving the upper mold 1 and the lower mold 2 to close the molds. Wherein, the upper die 1 and the lower die 2 are relative up and down, the lower surface of the upper die 1 is provided with a tablet die head 11, and the upper surface of the lower die 2 is provided with a support member 21, and the support member 21 and the tablet die head 11 are all connected to each other. The single inserts on the circuit board correspond one-to-one, that is, the number of supports 21 and tablet dies 11 is equal to the number of single inserts, and the distribution position must be the same as that of the single inserts. The purpose is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com