Formula of granular calcium carbonate capable of being directly pressed into tablets for health products

A technology of granular calcium carbonate and calcium carbonate, which is applied in the field of microorganisms to achieve the effects of high content, enhanced physique and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

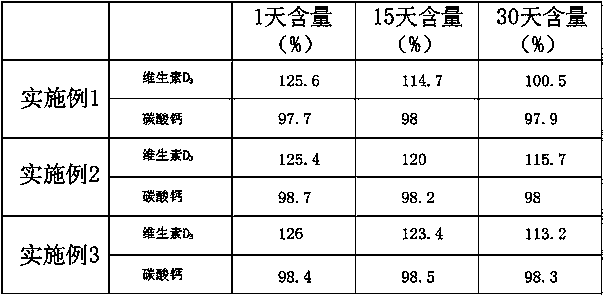

Embodiment 1

[0027] A formula of granular calcium carbonate that can be directly compressed into tablets for health care products, including the following ingredients: 800 parts of calcium carbonate, 680 parts of magnesium carbonate, 0.6 parts of vitamin D3 powder, 140 parts of beeswax, 268 parts of purified water, film coating premix 50 parts of agent, 400 parts of crospovidone, 1 part of tocopherol.

[0028] As a kind of optional technical scheme of the present invention: comprise the following steps:

[0029] A: Add calcium carbonate, calcium carbonate, magnesium carbonate, crospovidone, an appropriate amount of purified water and tocopherol into the wet granulator, then add an appropriate amount of binder for stirring, and stir the raw materials to make calcium carbonate granules. Calcium carbonate particles are dried;

[0030] B: Then screen the calcium carbonate particles after drying, and the size and quality of the calcium carbonate particles are consistent;

[0031] C: Then put ...

Embodiment 2

[0037] A formula of granular calcium carbonate that can be directly compressed into tablets for health products, including the following ingredients: 850 parts of calcium carbonate, 590 parts of magnesium carbonate, 1.3 parts of vitamin D3 powder, 130 parts of beeswax, 278 parts of purified water, and premixed film coating 33 parts of agent, 70 parts of crospovidone, 0.8 part of tocopherol.

[0038] As a kind of optional technical scheme of the present invention: comprise the following steps:

[0039] A: Add calcium carbonate, calcium carbonate, magnesium carbonate, crospovidone, an appropriate amount of purified water and tocopherol into the wet granulator, then add an appropriate amount of binder for stirring, and stir the raw materials to make calcium carbonate granules. Calcium carbonate particles are dried;

[0040] B: Then screen the calcium carbonate particles after drying, and the size and quality of the calcium carbonate particles are consistent;

[0041] C: Then pu...

Embodiment 3

[0047] A formula of granular calcium carbonate that can be directly compressed into tablets for health products, comprising the following ingredients: 900 parts of calcium carbonate, 500 parts of magnesium carbonate, 2 parts of vitamin D3 powder, 100 parts of beeswax, 288 parts of purified water, film coating premix 15 parts of agent, 100 parts of crospovidone, 0.6 parts of tocopherol.

[0048] As a kind of optional technical scheme of the present invention: comprise the following steps:

[0049] A: Add calcium carbonate, calcium carbonate, magnesium carbonate, crospovidone, an appropriate amount of purified water and tocopherol into the wet granulator, then add an appropriate amount of binder for stirring, and stir the raw materials to make calcium carbonate granules. Calcium carbonate particles are dried;

[0050] B: Then screen the calcium carbonate particles after drying, and the size and quality of the calcium carbonate particles are consistent;

[0051] C: Then put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com