Novel macromolecule resistance-reducing agent and preparation method thereof

A drag-reducing agent and macromolecule technology, which is applied in the field of macromolecule new-type drag-reducing agent and its preparation, can solve problems such as the easy loss of drag-reducing agent, the stability of resistance-reducing agent, and the corrosion of steel grounding bodies, and achieve a good effect of reducing resistance , Long service life, less corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

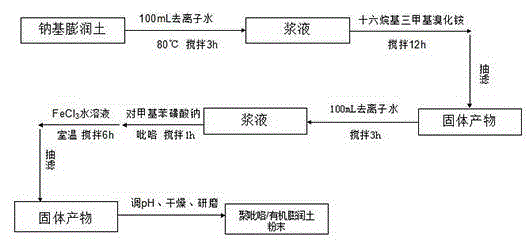

[0029] Example 1 The method for preparing a macromolecular drag reducing agent is as follows.

[0030] (1) Weigh 20g of sodium bentonite into a beaker, then add 100mL of deionized water, stir at 80°C for 3 hours, then add 5g of completely dissolved cetyltrimethylammonium bromide, and continue After stirring for 12 hours, the resulting solution was filtered, and the filtered product was washed with deionized water until there was no foam, and dried in a vacuum oven to obtain an organically modified bentonite.

[0031] (2) Add a certain amount of vacuum-dried organic bentonite to a beaker, add 100ml of water, stir at 60°C for 3 hours at high speed to form a uniform suspension, and then cool down to room temperature. Then add 10.5g of doping agent sodium p-toluenesulfonate, then drop into 5g of pyrrole monomer, stir and disperse for about 1 hour, slowly drop into 150ml of 1mol / L ferric chloride aqueous solution with dropping funnel, and continue the reaction 6 h. Let stand to c...

Embodiment 2

[0032] Example 2 The method for preparing a macromolecular drag reducing agent is as follows.

[0033] (1) Weigh 20g of sodium bentonite into a beaker, then add 100mL of deionized water, stir at 80°C for 3 hours, then add 6g of completely dissolved cetyltrimethylammonium bromide, and continue After stirring for 12 hours, the resulting solution was filtered, and the filtered product was washed with deionized water until there was no foam, and dried in a vacuum oven to obtain an organically modified bentonite.

[0034] (2) Add a certain amount of vacuum-dried organic bentonite to a beaker, add 100ml of water, stir at 60°C for 3 hours at high speed to form a uniform suspension, and then cool down to room temperature. Then add 8g of doping agent sodium p-toluenesulfonate, then drop in 6g of pyrrole monomer, stir and disperse for about 1h, then slowly drop in 175ml of 1mol / L ferric chloride aqueous solution with a dropping funnel, and continue the reaction for 6 h. Let st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com