Apparatus and method for simulating natural corrosion of reinforced concrete

A reinforced concrete and concrete layer technology, applied in the field of reinforced concrete, can solve the problems of long time, limited sampling samples, low scientific research efficiency, etc., and achieve the effect of accurate simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

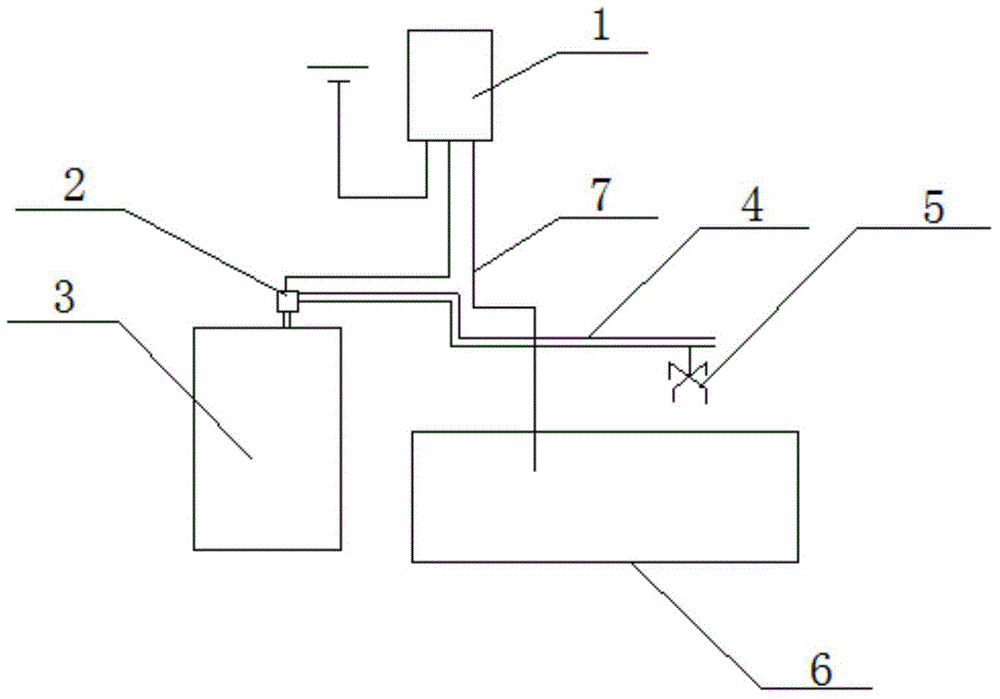

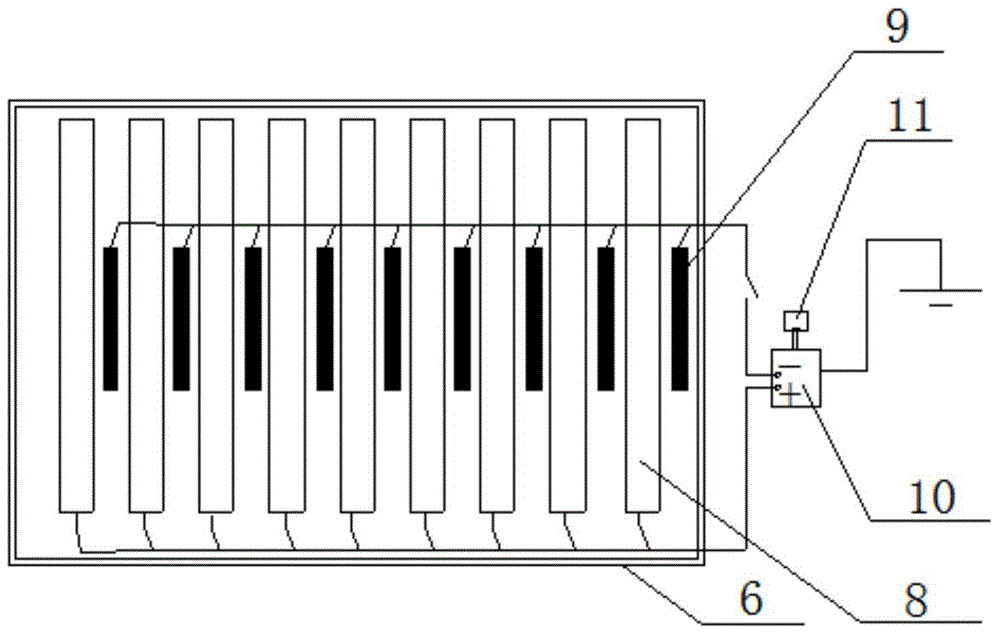

[0042] to combine figure 1 and 2 The device for simulating the natural corrosion of reinforced concrete in this embodiment includes a controller 1, a solenoid valve 2, a liquid storage tank 3, a liquid outlet pipe 4, a nozzle 5, an experimental tank 6, a humidity sensor 7, a test piece to be corroded 8, and an electrode 9 , DC stabilized power supply 10 and data recorder 11, wherein:

[0043] The model of controller 1 is DHT11, the model of solenoid valve 2 is 2W-500-50, and the model of humidity sensor 7 is HTF3223.

[0044] The controller 1 is respectively connected to the humidity sensor 7 and the solenoid valve 2, the liquid storage tank 3 is connected to the liquid outlet pipe 4, and the end of the liquid outlet pipe 4 is connected to the nozzle 5, and the test tank 6 is placed under the nozzle 5, and the nozzle 5 stores the liquid The liquid in the tank 3 is sprayed into the test tank 6, the electromagnetic valve 2 is arranged on the liquid outlet pipe 4 to control its...

Embodiment 2

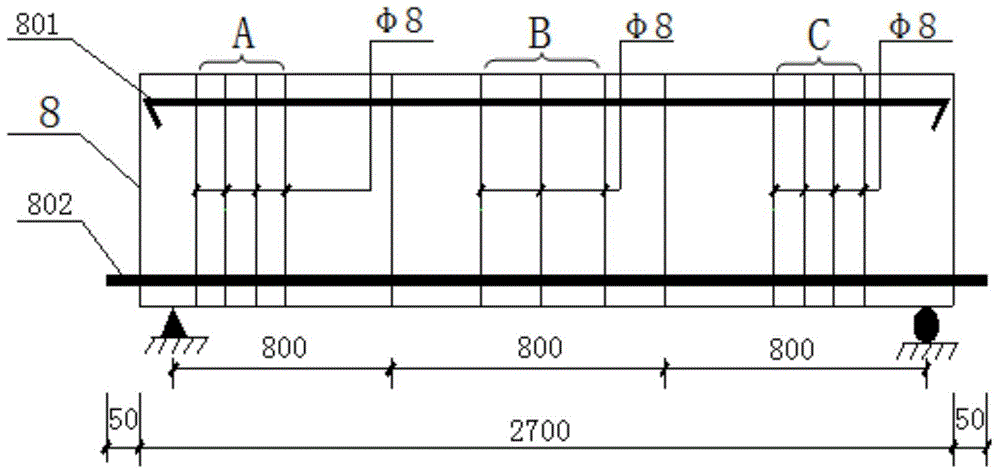

[0047] Such as image 3 and Figure 4 As shown, first make the specimen 8 to be corroded: the specimen is designed as a beam with suitable reinforcement, and the positioning of the steel bars in the process of concrete pouring can be realized by using wooden formwork. The length is 2700mm; the second longitudinal reinforcement 802 uses two HRB400 grade φ20mm steel bars, the first longitudinal reinforcement 801 is two HRB400 grade φ14mm steel bars, the two first longitudinal reinforcements 801 and the two second longitudinal reinforcements 802 form a section of A rectangular frame structure, the frame structure is bound and fixed through the first stirrup area A, the second stirrup area B and the third stirrup area C arranged in sequence along the length direction, and the first stirrup area A is provided with parallel stirrups, The distance between the adjacent stirrups in the first stirrup area A is 100mm, the second stirrup area B is provided with parallel stirrups, the dis...

Embodiment 3

[0050] The test piece in embodiment two is placed in the device among embodiment one and carries out corrosion test, and process is as follows:

[0051] The moisturizing material used in this embodiment is Weihe fine sand with a particle size of 0.1 to 0.25mm and a mud content (mass fraction)≤5.0%. After the river sand is cleaned, it is completely dried in the air, and the treated river sand is sprayed with a mass percentage concentration of 3.5% to 5% NaCl solution to keep the river sand humidity at 40% to 45%;

[0052] The current intensity of the electrode 9 of the present embodiment is 40μA / cm 2 ;

[0053] Such as figure 2 As shown, the test tank 6 is built with brick masonry. The length of the test tank 6 is 4m, the width is 3.2m, and the height is 40cm. Inside, make the side (bottom surface) of the tensile longitudinal reinforcement of the test piece 8 to be corroded upward, so as to facilitate the observation of the corrosion state of the steel bar, and place a conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Crack width | aaaaa | aaaaa |

| Crack width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com