Automatic metal net roll flattening machine for cast asphalt pavement of road surface

An asphalt paving and pouring technology, which is applied in the field of metal mesh roll automatic flattening machine, can solve the problems of metal mesh transverse cracks and metal mesh instability, so as to improve construction quality, eliminate elastic bending, improve paving efficiency and The effect of paving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

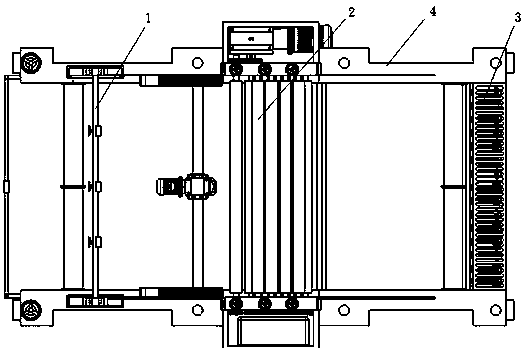

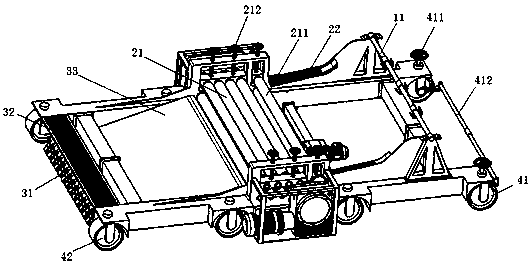

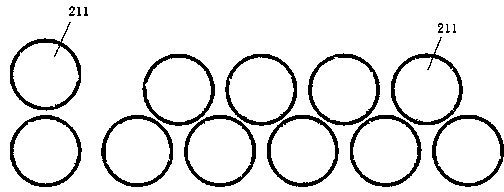

[0028] Embodiment 1, the metal mesh roll automatic flattener that is used for pavement pouring type asphalt pavement, the metal mesh roll is a copper wire mesh roll, and this road surface includes bridge deck, see figure 1 , figure 2 and Figure 7 , comprising an unwinding mechanism 1 for placing copper wire mesh rolls arranged on the vehicle frame 4, a flattening mechanism 2 for flattening copper wire mesh rolls, and a paving mechanism 3 for laying copper wire mesh, and the paving mechanism 3 includes pressing down Device 31, the pressing device 31 includes a pressing roller 311, and the pressing roller 311 is arranged above the place where the copper wire mesh is placed.

Embodiment 2

[0029] Embodiment 2, what adopted in the present embodiment is steel wire mesh coil, on the basis of embodiment 1, pavement mechanism 3 in the present embodiment also comprises road surface heating device 32, and road surface heating device 32 heats the asphalt of road surface, Increase the viscosity of the asphalt, combined with the lower pressure roller 311 to apply a vertical force, so that the steel wire mesh can be embedded in the road asphalt.

[0030] see Figure 7 , the road surface heating device 32 can also be connected with the lower pressure roller 311 through the tie rod 312, so that the lower pressure roller 311 has the function of heating the road surface asphalt and exerting a vertical downward force on the steel wire mesh at the same time, which can ensure that the lower pressure roller 311 is pressed The automatic healing of the asphalt pavement after passing can eliminate the adhesion of asphalt on the lower pressure roller 311, thereby ensuring the flatness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com