Method for treating chemical nickel plating concentrated waste liquid by solvent extraction method and ion exchange method

An ion exchange method and electroless nickel plating technology, which is applied in the field of solvent extraction method-ion exchange method to regenerate concentrated electroless nickel plating waste liquid, to achieve the effect of simple extraction and recovery process, good extraction effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 LIX984 is used to recover nickel in waste electroless nickel plating solution.

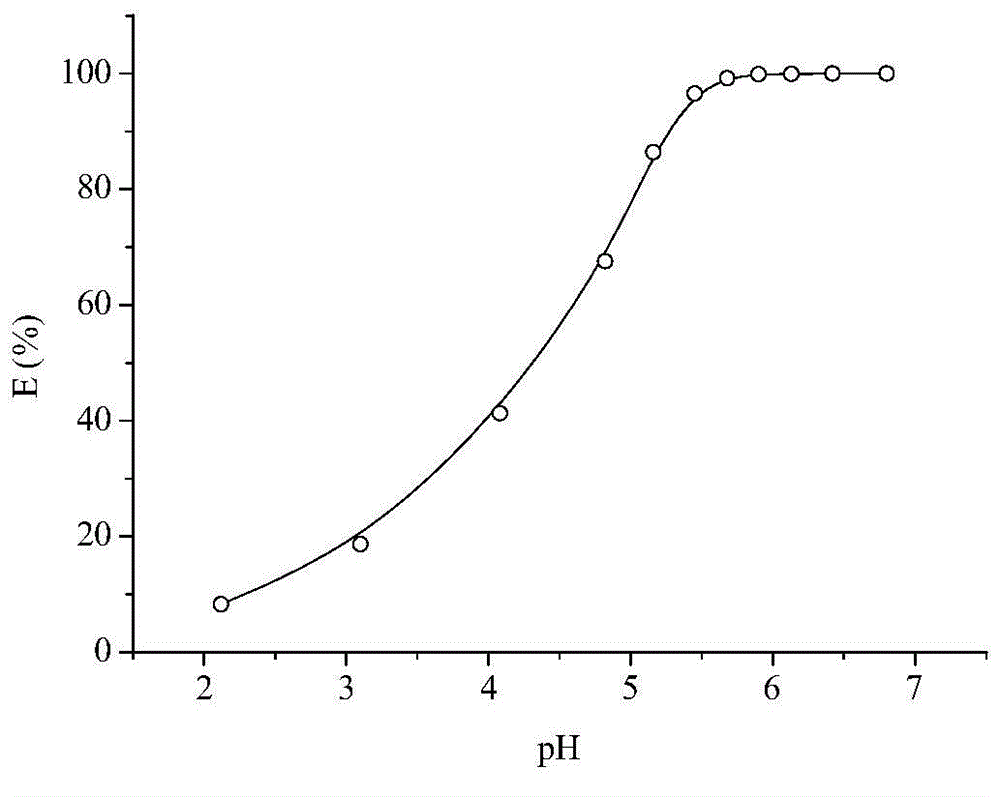

[0039] Take an appropriate amount of actual waste liquid of electroless nickel plating, measure the nickel concentration in the waste liquid to be 0.069mol / L, use 2mol / LH 2 SO 4 and 3mol / LNaOH to adjust the pH gradually from 2 to 7, using 20% volume fraction of LIX984 and 80% volume fraction of diluent D70 as the organic phase extractant.

[0040] Mix 10 mL of the aqueous phase and 10 mL of the organic phase in an Erlenmeyer flask, place in a constant temperature water bath shaker (25° C.) and shake at a speed of 140 rpm for 4 h. After shaking, the solution in the Erlenmeyer flask was poured into a 30ml centrifuge tube, put into a centrifuge and centrifuged at 2000rpm for 5min. After centrifugation, take out the centrifuge tube, suck out the organic phase with a straw, pour the remaining water phase into a small beaker, remove the organic phase completely with Whatman test pap...

Embodiment 2

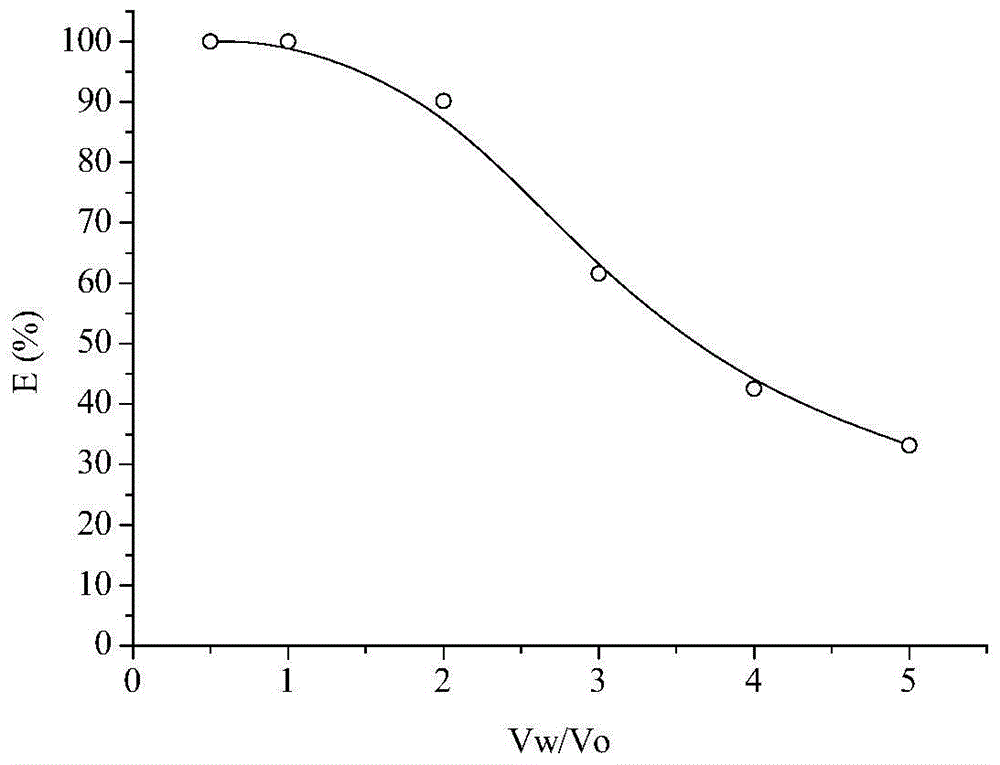

[0045] Embodiment 2 is to the stripping of the organic phase of loading nickel.

[0046] The organic phase of the loaded nickel that 3ml embodiment 1 obtains and the H of 1mol / L 2 SO 4 Transfer 9mL of the solution into a 30mL centrifuge tube, fix it in a vertical shaker, and shake it for 0.5, 1, 2, 3, 5, 10, 20, 40 minutes respectively. After the shaking is over, put it in a centrifuge and centrifuge at 2000rpm for 5 minutes. After centrifugation, the centrifuge tube is taken out, and the organic phase is sucked out with a straw to obtain recovered extractant. The remaining water phase was poured into a small beaker, and the organic phase was completely removed with Whatman test paper. After that, 1 mL of the water phase was placed in a centrifuge tube, and diluted to 10 mL with 0.1 mol / L dilute nitric acid, and the metal in the water phase was determined by ICP-OES. nickel content. The stripping efficiency is represented by S. Obtain the relationship diagram of stripping ...

Embodiment 3

[0048] Embodiment 3 Continuous solvent extraction recovers the nickel in the electroless nickel plating waste liquid.

[0049] The mixing clarifier is a device used for countercurrent continuous extraction. The mixing clarifier mainly includes a mixing chamber and a clarification chamber. The two phases enter the mixing chamber and are fully mixed by the agitator. After the mixing chamber is filled with liquid, it overflows into the clarification chamber. Due to the difference in density of the two phases, the phases are naturally separated and continuous in the clarification chamber by gravity. The experiments of embodiment 3 and embodiment 4 were all carried out in the mixing clarifier.

[0050] With the extraction agent-LIX984 of 20% by volume fraction, the co-extractant P5709 of 2% by volume fraction and the diluent D70 of volume fraction 78 as organic extraction phase (organic phase), water phase is simulated waste liquid with electroless nickel plating, and composition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com