Paper plastic cup and production technology thereof

A production process and technology for paper-plastic cups, applied in the field of liquid food packaging, can solve the problems of environmental and human health hazards, environmental pollution of adhesives, poor surface flatness, etc., achieving a high degree of automation, improving production efficiency, high the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

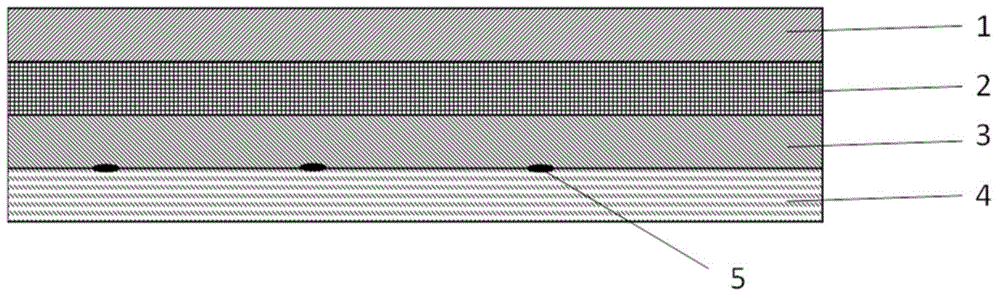

Image

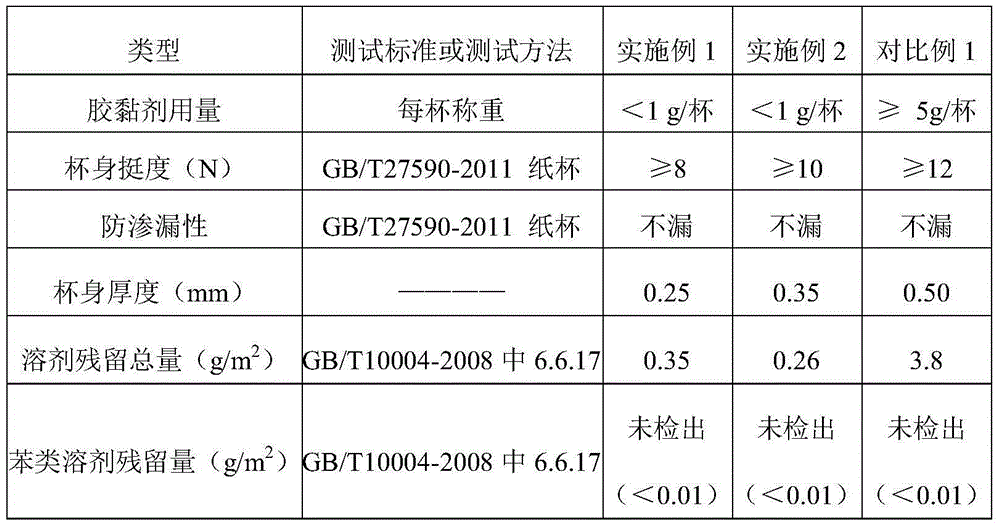

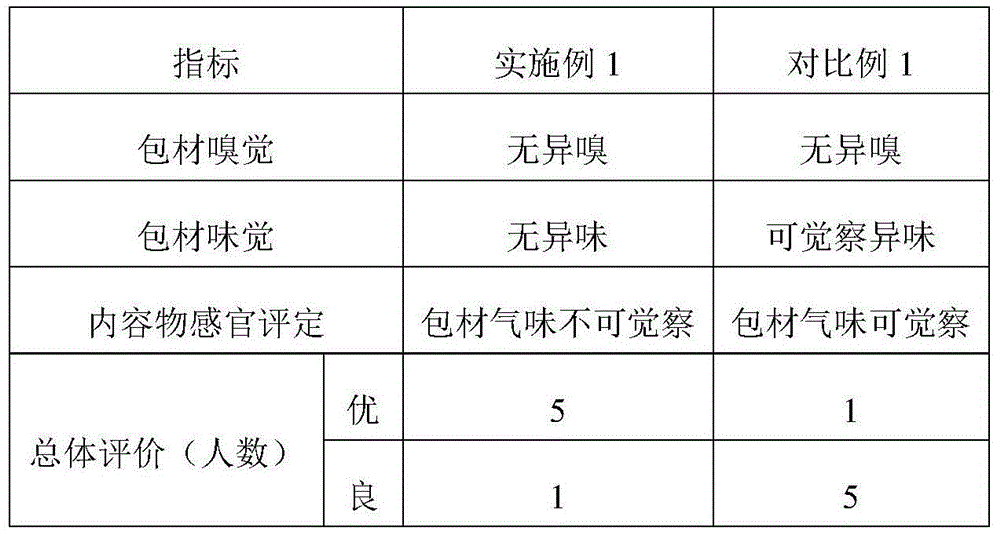

Examples

Embodiment 1

[0040] The preparation method of the paper-plastic cup of the present embodiment comprises the steps:

[0041] (1) The paper is flexographically printed by a unit-type flexo printing machine, and a printing ink layer is formed on one surface of the paper; the ink used is the water-based acrylic resin ink of Shanghai Shengweike Ink Co., Ltd.; the weight of the paper 100g / m 2 ; In the flexographic printing, in order to ensure that each dot on the printing plate can be inked, the number of anilox rolls of the anilox roller is selected to be ≥350 lines / inch, and the number of screen lines to be printed is ≥150 lines / inch;

[0042] (2) Extrusion compound machine is used, and the extrusion coating process is carried out according to the following steps: the plastic particles are plasticized by the screw and then extruded from the T-shaped die, stretched and attached to the surface of the printing ink layer, and formed after cooling and setting One plastic layer; no adhesive and no ...

Embodiment 2

[0049] In this embodiment, except for the following conditions, the remaining control conditions are the same as in Embodiment 1.

[0050] (1) Paper weight is 130g / m 2 ;The ink used is the flexographic UV ink of Hanghua Ink Chemical Company

[0051] (2) In the extrusion coating process, the melt temperature after plasticization is 340°C, the thickness of the plastic layer is 10μm; the air gap distance between the die lip and the cooling roller is 100mm;

[0052] (3) The adhesive used is QY-329 from Jiashan Pamir Latex Paint Factory; the inner plastic cup is a commercially available 200ml polystyrene cup with a weight of about 6g.

Embodiment 3

[0054] In this embodiment, except for the following conditions, the remaining control conditions are the same as in Embodiment 1.

[0055] (1) The weight of paper is 150g / m 2 ;

[0056] (2) In the extrusion coating process, the melt temperature after plasticization is 320°C, the thickness of the plastic layer is 12μm; the air gap distance between the die lip and the cooling roller is 120mm.

[0057] (3) The adhesive used is Q2283 from Henkel, Germany; the inner plastic cup is a commercially available 200ml polystyrene cup with a weight of about 6g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com