Lead bent nose clamp

A technology of bending noses and wires, applied in pliers, manufacturing tools, etc., can solve problems such as failure to meet standardization requirements, failure to meet standardization requirements, poor contact, etc., to improve work efficiency, increase use value, and avoid virtual connections and the effect of poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with the accompanying drawings and specific examples below, while those skilled in the art can better understand the present invention, but the present invention is not limited thereby.

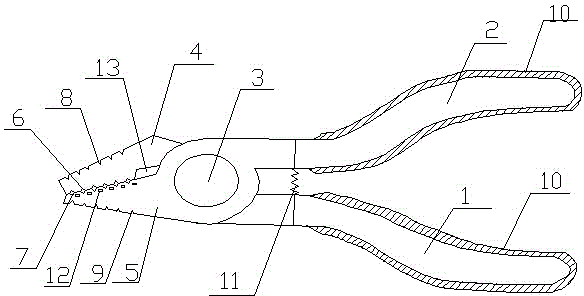

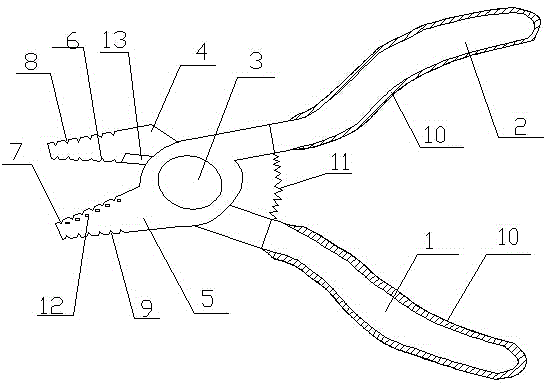

[0026] A wire bending nose pliers, comprising a first handle 1 and a second handle 2 that are axially connected, the front end of the first handle 1 is fixedly connected with a first pliers mouth 4, and the front end of the second handle 2 is fixedly connected with a second pliers mouth 5, the first pliers mouth 4 is provided with a number of first grooves 6 on the contact surface with the second pliers mouth 5, and the contact surface with the first pliers mouth 4 on the second pliers mouth 5 is provided with the second pliers mouth 5 A second groove 7 matched with a groove 6, the first pliers mouth 4 and the second pliers mouth 5 are tapered after closing, the outer wall of the first pliers mouth 4 is provided with the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com