Method for curing and shaping slurry spray used for 3D printing

A 3D printing and materials technology, applied in the direction of additive processing, etc., can solve the problems of high impact force of powder, poor surface quality of parts, short life, etc., and achieve the effect of good parts performance, high production efficiency and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

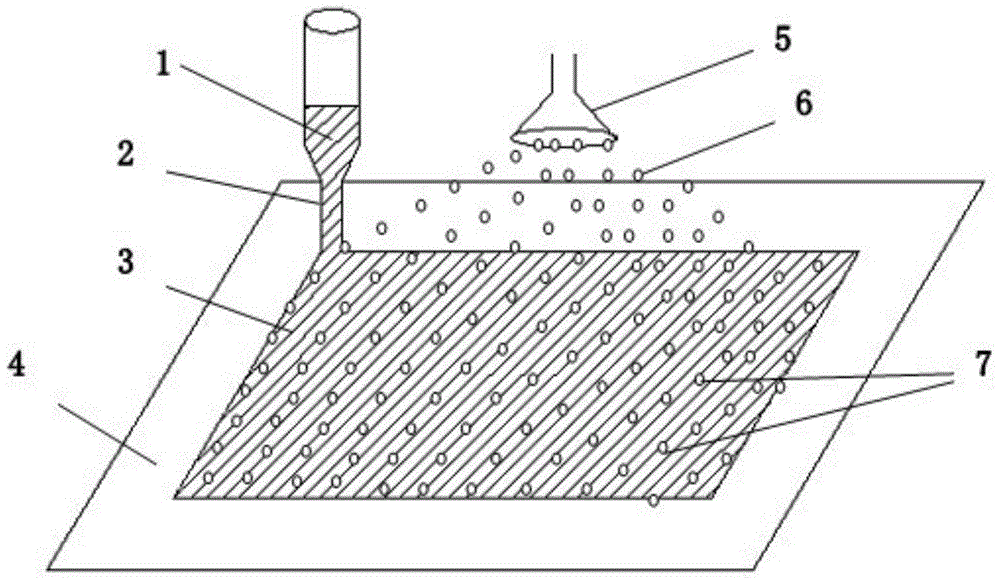

[0024] Implementation example 1: 3D printing the green body of stainless steel metal parts by spray curing and shaping method

[0025] 1) Mix organic monomer hydroxyethyl methacrylate, solvent toluene, and initiator dibenzoyl peroxide to prepare a mixed solution, add stainless steel metal powder with a particle size of 1um to the mixed solution under shearing and stirring, and prepare Form a stainless steel powder "ink" slurry with high solid phase and low viscosity;

[0026] 2) Printing of the front "ink" layer: the 3D printer prints the front "ink" layer of stainless steel powder according to the 2D contour section program diagram;

[0027] 3) Spray curing and shaping: The extrusion sprayer atomizes the liquid curing agent N,N-dimethylaniline into a particle size of 0.01% according to the mass ratio of the liquid curing agent N,N-dimethylaniline to the stainless steel powder layer to be cured mm of mist beads, the mist beads evenly fall into the surface of the "ink" layer t...

Embodiment 2

[0031] Implementation example 2: 3D printing alumina ceramic parts green body by spray curing shaping method

[0032] 1) Mix the organic monomer hydroxyethyl methacrylate, solvent toluene, and initiator dibenzoyl peroxide evenly to prepare a mixed solution, and add alumina ceramic powder with a particle size of 50um to the mixed solution under shearing and stirring, Preparation of alumina powder "ink" slurry with high solid phase and low viscosity;

[0033] 2) Printing of the front "ink" layer: the 3D printer prints out the front "ink" layer of alumina according to the 2D contour section program diagram;

[0034] 3) Spray curing and shaping: the squeeze sprayer atomizes the liquid curing agent polyetherimide into mist beads with a particle size of 1mm according to the mass ratio of the liquid curing agent polyetherimide to the alumina powder layer to be cured at 2%. The beads fall evenly on the surface of the "ink" layer, forming a solidified layer with a thickness of 200um, ...

Embodiment 3

[0038] Implementation example 3: 3D printing of NdFeB magnetic alloy parts by spray curing method

[0039] 1) Mix organic monomer hydroxyethyl methacrylate, solvent toluene, and initiator dibenzoyl peroxide to prepare a mixed solution, and add NdFeB magnetic alloy with a particle size of 25um to the mixed solution under shearing and stirring Powder, prepared into a high-solid low-viscosity alumina powder "ink" slurry;

[0040] 2) Printing of the front "ink" layer: the 3D printer prints the front "ink" layer of NdFeB powder according to the 2D contour section program diagram;

[0041] 3) Spray curing and shaping: The extrusion sprayer atomizes the liquid curing agent ethylenediamine into fog beads with a particle size of 0.5mm according to the mass ratio of the liquid curing agent ethylenediamine to the NdFeB powder layer to be cured, and the fog beads are uniform It has to fall into the surface of the "ink" layer to form a solidified layer with a thickness of 100um, and solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com