Machines for driving lifts

A technology of elevators and brakes, which is applied in the field of electric mechanical devices, can solve problems such as laborious motor assembly, reduce wear and noise, and improve mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

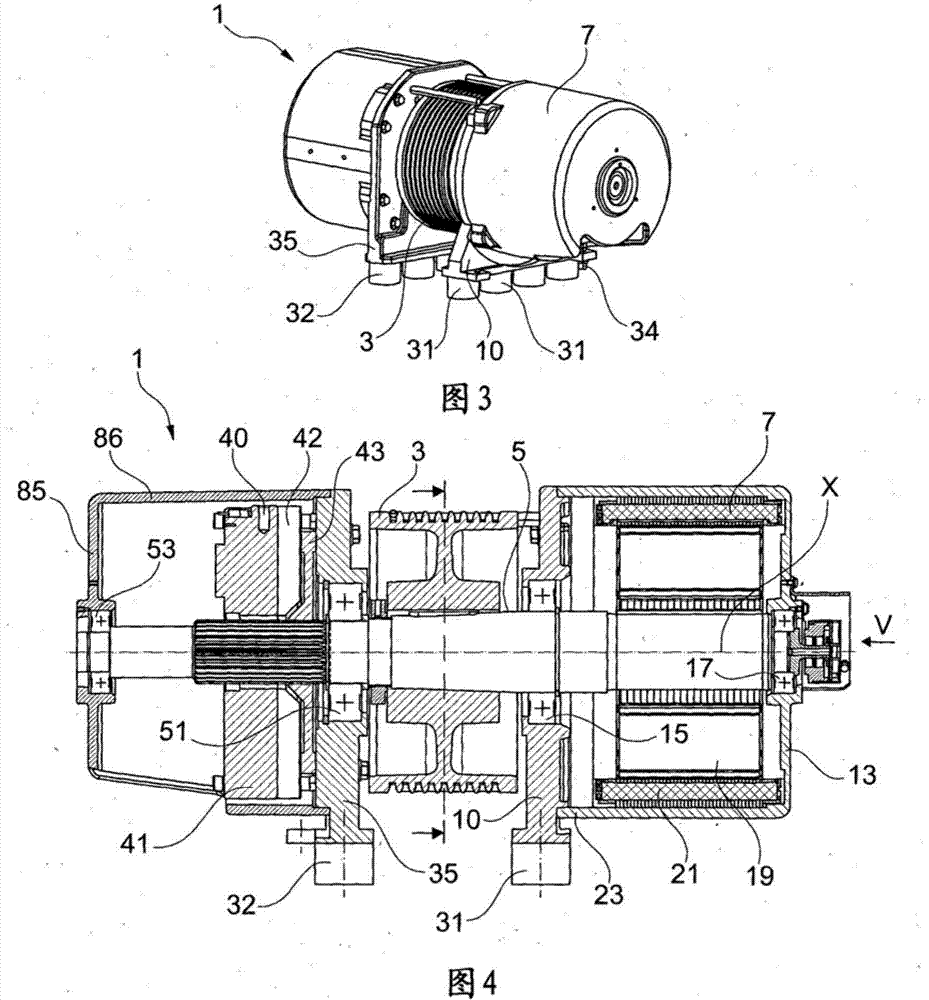

[0063] The mechanical device 1 according to the invention shown in FIGS. 3 to 5 comprises a pulley 3 mounted on a shaft 5 , which rotates about a preferably horizontal axis of rotation X .

[0064] The pulley 3 may be mounted on the shaft 5 by any suitable known means, for example, by a shrinking, conical tapered fit or a spline and adapter.

[0065] The mechanism 1 comprises a motor 7 on one side of the pulley 3, the motor 7 comprising a first front support 10 and a rear support 13 carrying a front rolling bearing 15 and a rear rolling bearing 17 respectively, the first front support 10 supporting the motor 7 , the rolling bearing is, for example, a ball bearing.

[0066] The motor 7 also comprises a rotor 19 and a stator 21 carried by a housing 23 extending between the first front support 10 and the rear support 13 .

[0067] Housing 23 and rear support 13 may be made in one piece as shown, or in the form of parts to be assembled, as shown in FIG. 8 .

[0068] The rotor 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com