Touch panel module

一种触控面板、模组的技术,应用在仪器、电数字数据处理、数字数据处理零部件等方向,能够解决限制线路配置调整弹性、导线与金属接点占用过多面积等问题,达到体积缩减、减少配置面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

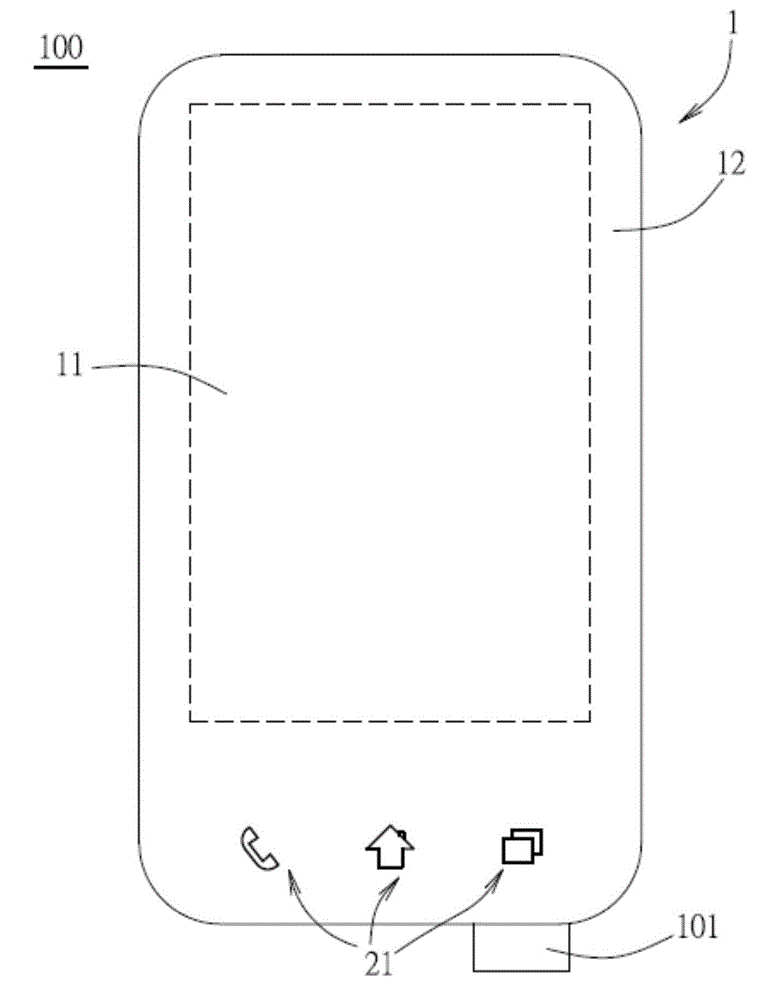

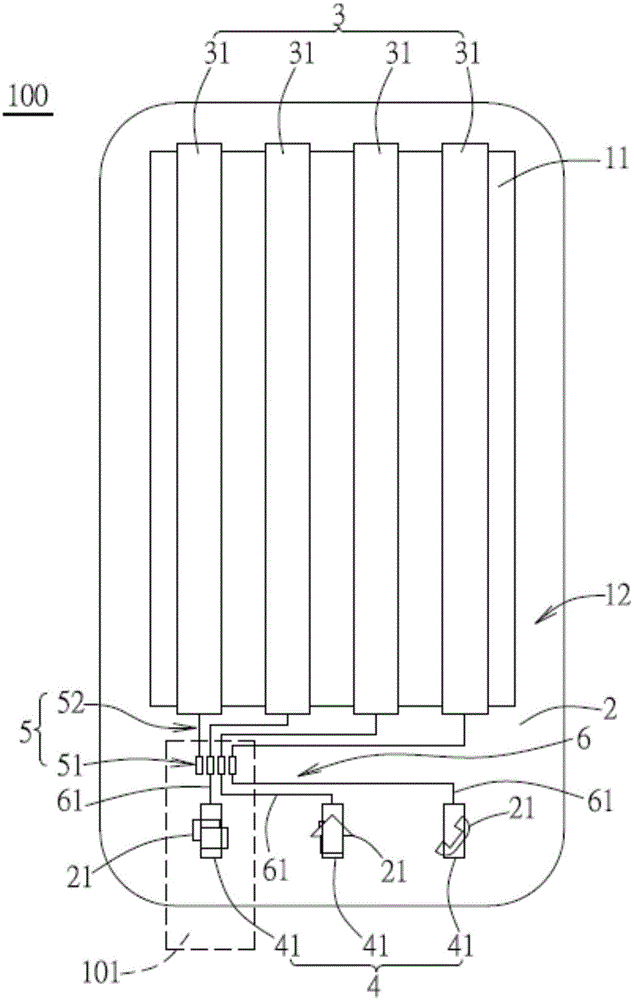

[0024] refer to figure 1 and figure 2 , is the first preferred embodiment of the touch panel module 100 of the present invention. The touch panel module 100 can be applied to various electronic devices such as mobile phones and tablet computers, and is not limited to specific application forms.

[0025] The touch panel module 100 of this embodiment includes a substrate 1, a shielding layer 2, a first sensing unit 3, at least one (here three, but not limited to) second sensing unit 4, a The overlapping portion 5 and a connecting portion 6 form an electrical connection with an external circuit (not shown) through a flexible circuit board 101 .

[0026] The substrate 1 has light transmission and is divided into a visible area 11 and a non-visible area 12 adjacent to the visible area 11 , which can be made of glass material, but not limited thereto.

[0027]The shielding layer 2 is arranged on the non-visible area 12 of the substrate 1, and can be made of materials with light-...

no. 2 example

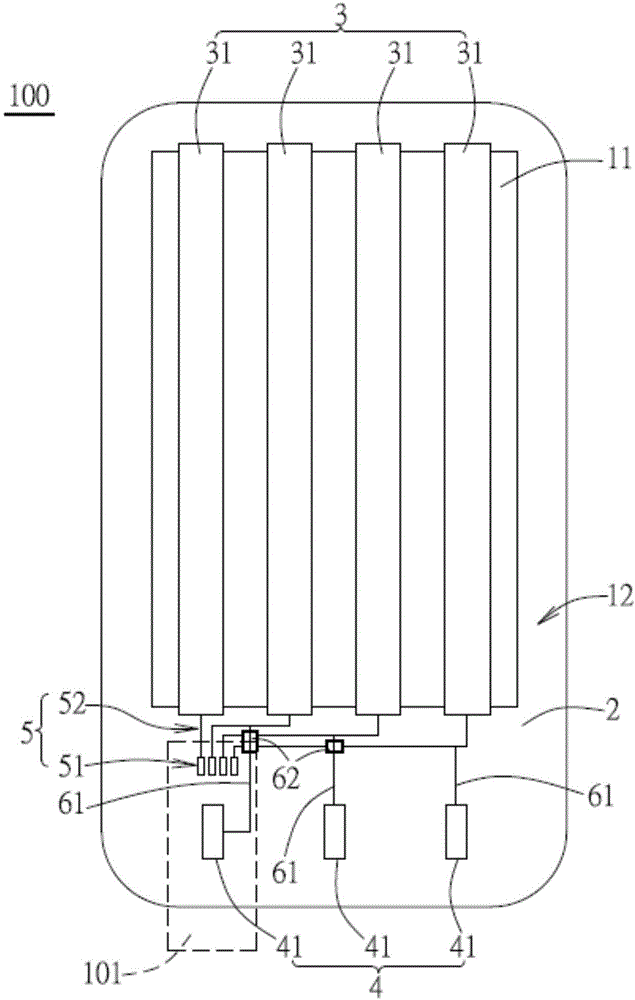

[0034] refer to image 3 , is the second embodiment of the touch panel module 100 of the present invention. The touch panel module 100 of this embodiment is substantially the same as the aforementioned first embodiment, the main difference lies in the implementation of the connecting portion 6 .

[0035] In this embodiment, the connecting portion 6 further includes at least one (here, two are used as an example, but not limited thereto) first insulating layer 62, and the circuit wiring method of the first wire 52 and the first sub-wire 61 is the same as the aforementioned The first embodiment is different. Specifically, the first wires 52 extend between the first electrode 31 and the first sub-electrode 41, and the first sub-wires 61 cross the first wires 52 in an electrically insulated manner to electrically insulate Connect to the first wire 52 to which it belongs. The first insulating layer 62 is respectively arranged at the overlapping positions of the first wires 52 an...

no. 3 example

[0039] refer to Figure 4 , Figure 5 , is the third embodiment of the touch panel module 100 of the present invention. The touch panel module 100 of this embodiment is substantially the same as the aforementioned first embodiment, the main difference lies in the implementation of the sensing electrode structures of the first sensing unit 3 and the second sensing unit 4 .

[0040] In this embodiment, the first sensing unit 3 and the second sensing unit 4 respectively have a biaxial sensing electrode structure, so the first sensing unit 3 also includes at least one (here five are taken as an example, but not limited to this) The second electrode 32 and a second insulating layer 33, and the second sensing unit 4 also includes at least one (here three are used as an example, but not limited to) second sub-electrode 42 and a third insulating layer 43 . Therefore, both the overlapping portion 5 and the connecting portion 6 that provide the function of the conductive circuit have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com