Full-automatic pre-locking, rubber coating and electrical detection platform equipment and usage method

An electrical detection and fully automatic technology, applied in the direction of electrical program control, general control systems, instruments, etc., can solve the problems of unfavorable modern production, high labor intensity, complex process, etc., to achieve the scope of excavation, save space, and can highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, the present invention will be further described

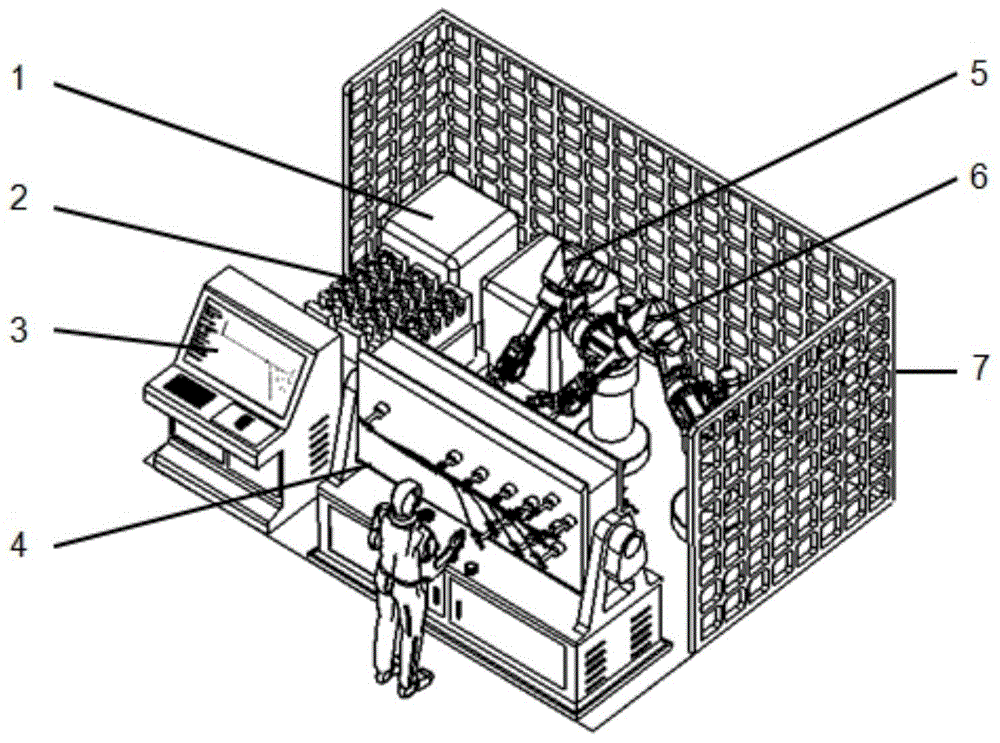

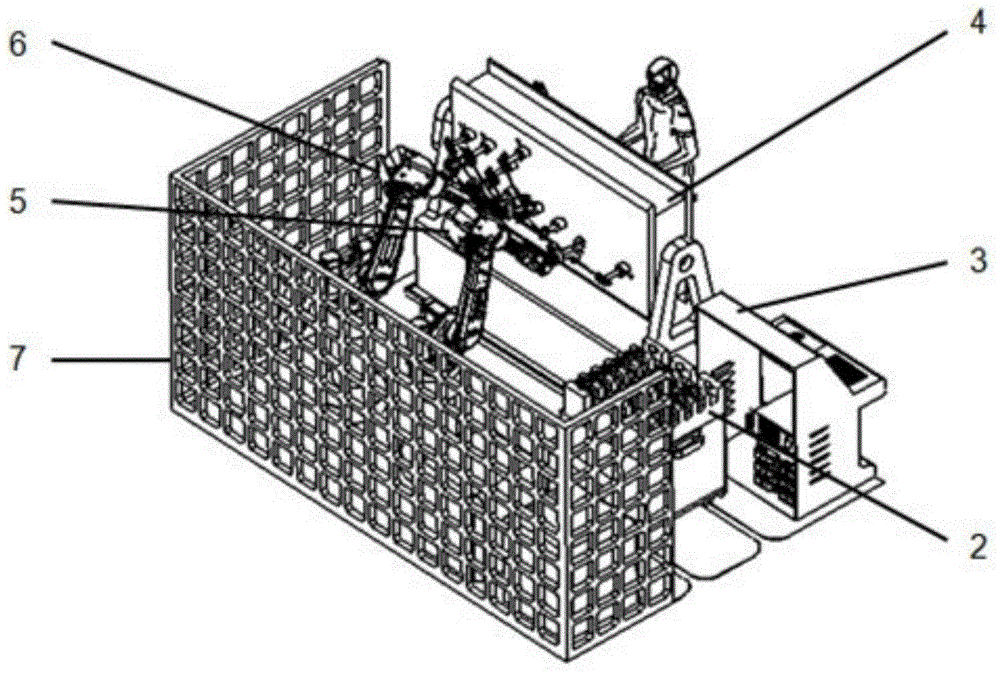

[0047] Such as figure 1 , figure 2 As shown, a fully automatic pre-locking, rubber coating, and electric detection platform equipment includes a robot control cabinet 1, a rubber coating machine tool library 2, a main console 3, an intelligent working platform 4, a rubber coating robot 5, an auxiliary robot 6 and a protective Column 7;

[0048] The intelligent work platform 4 and the total console 3 are arranged on the same horizontal line, and a guardrail 7 is arranged behind the intelligent work platform 4 and the total console 3, and the space enclosed by the intelligent work platform 4, the total console 3 and the guardrail 7 is There are two robot control cabinets 1 , a rubber-coating robot 5 , an auxiliary robot 6 and a rubber-coating machine warehouse 2 .

[0049] Such as image 3 As shown, the rubberizing machine tool library 2 includes a rubberizing machine he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com