Fuzzy predictive control system for combustion process of lime kiln as well as control method of system

A technology of fuzzy prediction and combustion process, applied in general control systems, control/regulation systems, adaptive control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

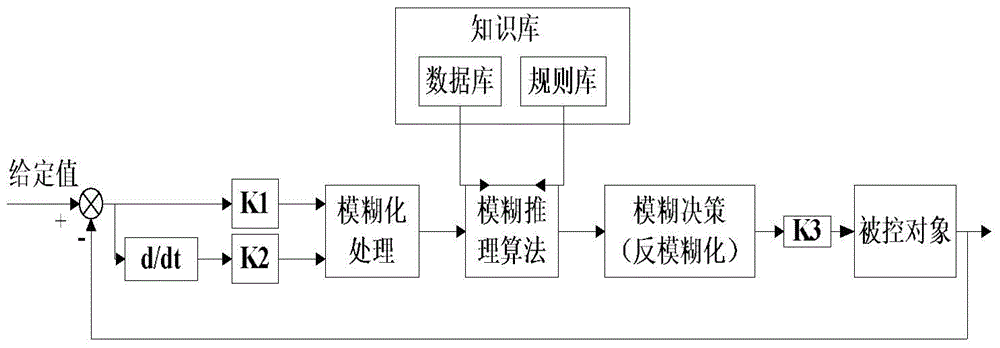

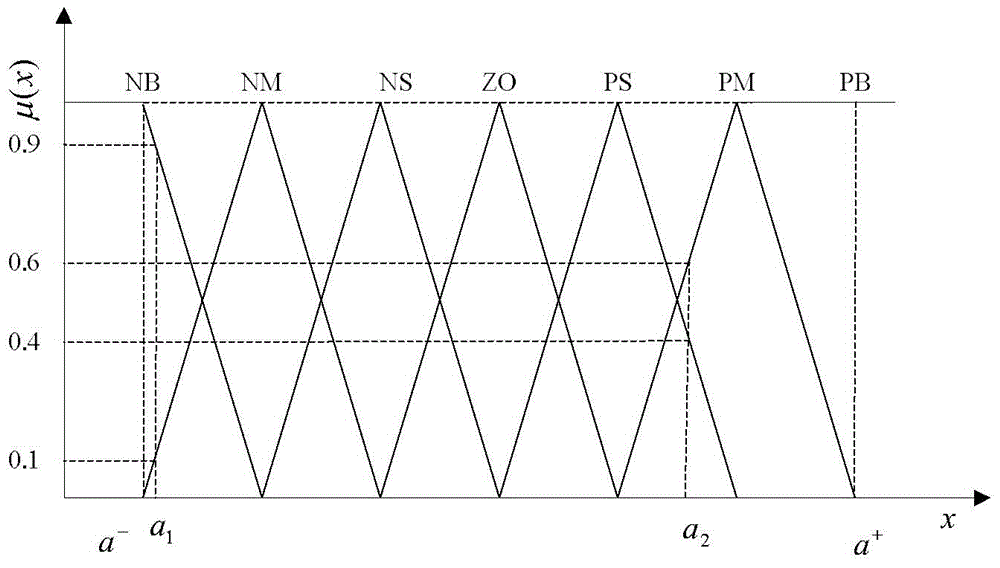

Method used

Image

Examples

Embodiment 1

[0204] The fuzzy predictive control system of this embodiment includes a reference information input module, fuzzy controller, fuel valve, lime kiln control device, prediction module, feedback module and correction module; reference information input module, fuzzy controller, fuel valve and lime kiln control The device is connected in series in sequence; the fuel valve is connected in series with the prediction module, the feedback module and the fuzzy controller in sequence; the fuel valve is also connected with the correction module; the correction module is connected with the prediction module; the lime kiln control device is simultaneously connected with the correction module, the feedback module and the reference information Input module connection.

[0205] When the fuzzy predictive control system of this embodiment is applied to the lime kiln of Meishan Iron and Steel Works, the specific process is as follows:

[0206] An approximate simplified mathematical model is est...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com