A zero-emission online precise chemical cleaning method and device for a tube-and-tube heat exchanger

A chemical cleaning, zero-emission technology, used in cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve the problems of wasting chemical cleaning agents and failing to reach cleaning concentrations, reducing cleaning costs, improving water quality, and avoiding Effects of direct pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

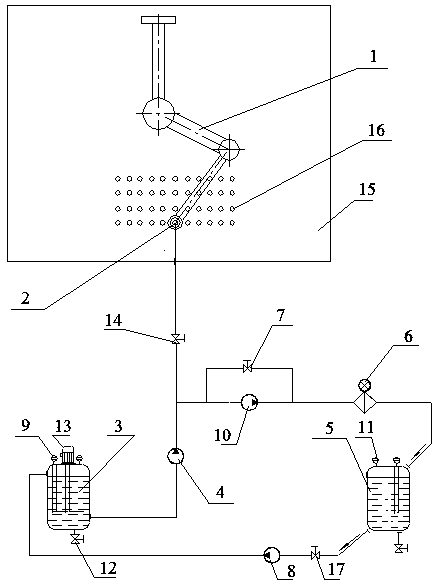

[0027] Such as figure 1 As shown, a zero-emission online precision cleaning device for tube and tube heat exchangers, the device includes a liquid distribution tank 3, and the liquid distribution tank 3 is equipped with an agitator 13 for stirring the cleaning liquid and a liquid level for observing the internal water level Device 11 is also equipped with a pH tester 9 for detecting the pH of the cleaning solution. The bottom of the liquid distribution tank 3 is connected to the liquid injection pump 4, and the liquid injection pump 4 is connected to the liquid injection valve 14. The cleaning liquid is injected into the heat exchange tube 16 through the descaling nozzle 2 on the positioning device 1 in the condenser 15, and the cleaning liquid drives off the cooling water in the heat exchange tube 16. , the desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com