Taper double control automatic vacuum lead smelting furnace

A lead melting furnace, automatic technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of increased raw material occupation, large energy consumption, poor thermal insulation performance of the furnace body, etc., to prevent occupational hazards and environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

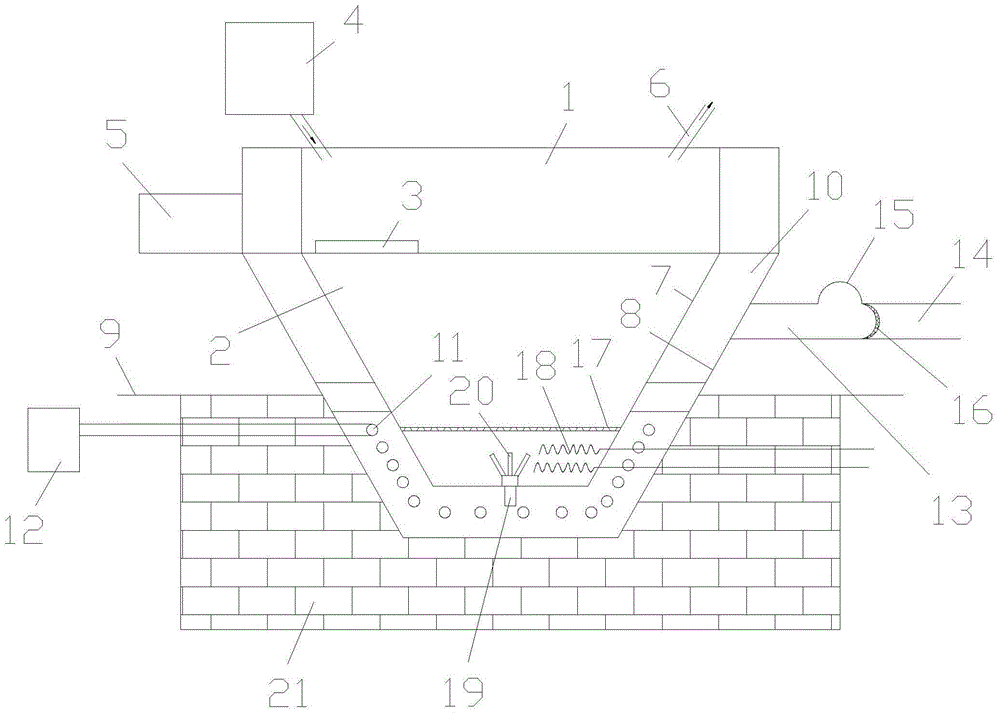

[0020] like figure 1 As shown, a conical dual-control automatic vacuum lead-melting furnace includes a furnace body, which is divided into a preheating chamber 1 at the upper part and a melting chamber 2 located at the lower part of the preheating chamber 1. The shape of the preheating chamber 1 is a cylinder Its bottom is used as the top cover of the melting chamber 2 to absorb the waste heat of the melting chamber 2. A 0.6*2cm groove is left around the bottom of the preheating chamber 1, and a lead drop port 3 is provided (closed in the preheating state) ; The side of the preheating chamber 1 is connected with an oxidation furnace waste heat collection device 4 (this device is a patent ZL201020609800.0 of the company), which absorbs the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com