Minimalistic LED recessed light

A technology of light-emitting diodes and downlights, which is applied to semiconductor devices, light sources, and electric light sources of light-emitting elements, and can solve problems such as the inability to truly realize environmental protection and energy saving, shortened service life, and inconvenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

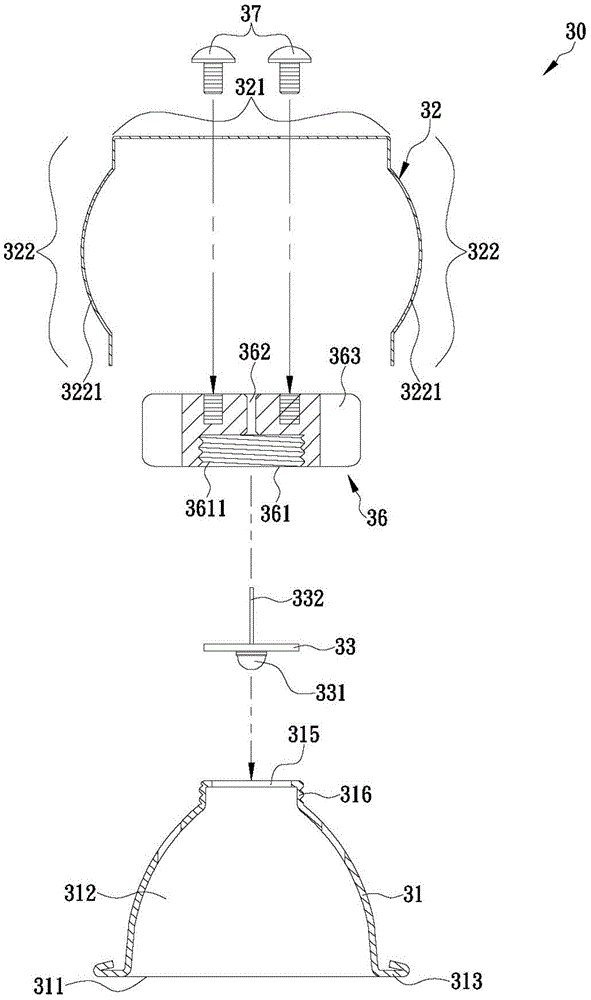

[0041] see image 3 , in the first preferred embodiment of the present invention, the extremely simplified LED downlight 30 includes a lamp cup 31, a lamp sheet 33, a heat sink 36 and an elastic support sheet 32, wherein the lamp cup 31 There is an opening 311 at the bottom of the lamp cup 31, a reflection space 312 is formed in the lamp cup 31, and a light transmission hole 315 is provided on the top of the lamp cup 31, the opening 311, the reflection space 312 and the light transmission hole 315 communicate with each other, the lamp cup 31 is adjacent to the periphery of the opening 311 and forms an annular flange 313 radially outward, the annular shape refers to a square, circular, annular wavy or other annular configuration, and the lamp cup 31 is adjacent to the light-transmitting hole 315 A first joint structure 316 is formed on the peripheral edge, and the first joint structure 316 can be an external thread or a tenon, please refer to Figure 4 , except that the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com