Anti-slip and anti-wear PVC composite floor with high-transmittance surface structure

A composite floor and wear-resistant layer technology, applied in the direction of coating, floor, layered products, etc., can solve the problems of easy aging, easy dirt, difficult maintenance, etc., and achieve good chemical corrosion resistance, strong deformation adaptability, The effect of saving installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

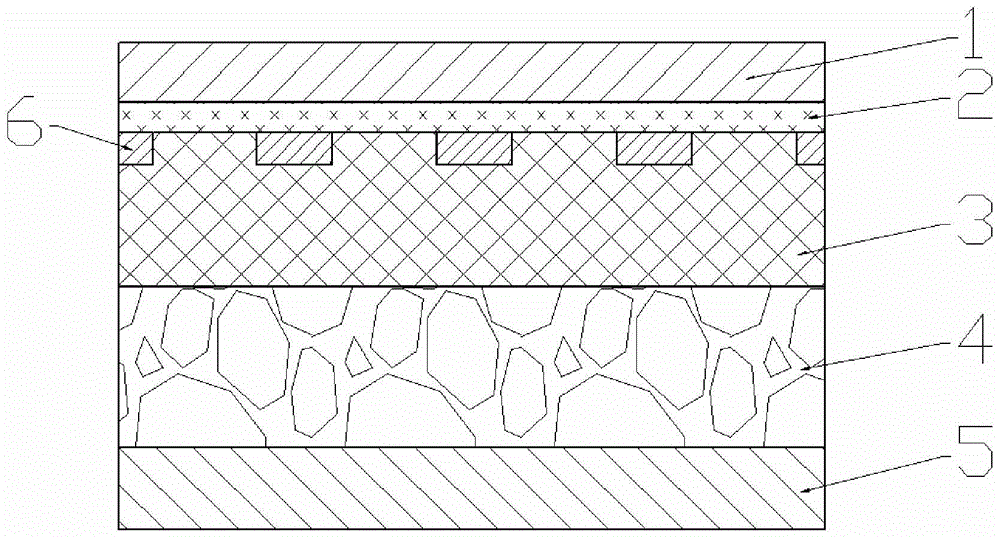

[0023] This embodiment provides a PVC composite floor with a non-slip, wear-resistant and high-permeability surface layer structure, the structure is as follows figure 1 As shown, it includes a PVC panel 3 and a primer layer 5, and is characterized in that a waterproof and heat-insulating layer 4 is provided between the PVC panel 3 and the primer layer 5, and the upper surface of the PVC panel 3 is covered with a high-density wear-resistant layer 2, which is high-density and durable The upper surface of the grinding layer 2 is coated with a high-transparency surface layer 1, and the upper surface of the PVC panel 3 is provided with a groove, and a carbon fiber strip 6 is arranged in the groove.

[0024] The aforementioned high-permeability surface layer 1 is a wear-resistant and anti-skid coating; the high-density wear-resistant layer 2 is a rubber layer; the waterproof and heat-insulating layer 3 is a polyethylene polypropylene fiber material layer.

[0025] The product in th...

Embodiment 2

[0027] This embodiment provides a PVC composite floor with a non-slip, wear-resistant and high-permeability surface layer structure. The preparation process of the wear-resistant and anti-slip coating selected for the high-permeability surface layer 1 includes the following specific steps:

[0028] (1) Weigh the following raw materials in parts by weight: 45 parts of nano-ceramic resin, 27 parts of alcohol-based silicone acrylic resin, 4 parts of nano-silicon dioxide, 0.01 part of nano-cerium oxide, 0.4 part of nano-titanium dioxide, 8 parts of urea, and 15 parts of ethanol , 0.1 part of citric acid, 4 parts of butyl acetate, 2 parts of isopropanol, 1 part of n-butanol, 5 parts of methyl acetoacetate;

[0029] (2) Mix nano-cerium oxide and nano-silicon dioxide with deionized water according to the proportion, add them to the mixer, stir at a speed of 350r / min for 18 minutes, then use ultrasonic dispersion, and grind to obtain a dispersion liquid for later use;

[0030] (3) Add...

Embodiment 3

[0033] This embodiment provides a PVC composite floor with a non-slip, wear-resistant and high-permeability surface layer structure. The preparation process of the wear-resistant and anti-slip coating selected for the high-permeability surface layer 1 includes the following specific steps:

[0034] (1) Weigh the following raw materials in parts by weight: 55 parts of nano-ceramic resin, 33 parts of alcohol-based silicone acrylic resin, 6.8 parts of nano-silicon dioxide, 0.05 part of nano-cerium oxide, 0.8 part of nano-titanium dioxide, 12 parts of urea, and 17 parts of ethanol , 0.3 parts of citric acid, 8 parts of butyl acetate, 4 parts of isopropanol, 2 parts of n-butanol, 9 parts of methyl acetoacetate;

[0035] (2) Mix nano-cerium oxide and nano-silicon dioxide with deionized water according to the proportion, add them to the agitator, stir at a speed of 370r / min for 15min, then use ultrasonic dispersion, and grind to obtain a dispersion liquid for later use;

[0036] (3) Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com