Straw stalk roof panel with heat dissipation function

A technology of straw straw and roof panels, which is applied to roofs using tiles/slate tiles, roofs, and roofs using flat panels/curved panels, etc., can solve the problems of complex construction technology, poor comfort, and high cost, and achieve simple construction technology, Simple to make, high radiant heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

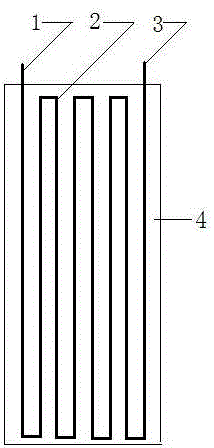

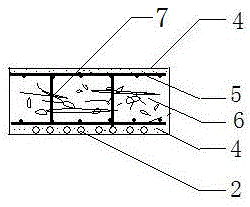

[0017] Embodiment 1: Taking the manufacture of a roof panel with a size of 2400mm×800mm as an example, the thickness is 250mm according to the requirements of thermal insulation performance and bearing capacity. First make the straw sandwich layer 6 with a thickness of 190 mm, cut to size, sprinkle a small amount of water on the straw sandwich layer 6 for wetting treatment, and smooth the surface, and trim the corners of the straw sandwich layer neatly. After the straw sandwich layer 6 is slightly dry, a steel wire mesh 5 is laid on both sides thereof. The steel wire diameter of the steel wire mesh 5 is 3mm, and the grid size is 12mm×12mm. At the same time, vertical steel wires 7 with a length of 200 mm and a diameter of 3 mm are welded and fixed, and the distance between the vertical steel wires 7 is 200 mm. After the vertical steel wire 7 is welded and fixed, the upper and lower spacing of the steel wire mesh 5 is 200mm. In the lower part of the steel wire mesh 5, the heat ...

Embodiment 2

[0018] Embodiment 2: Take a single-storey house as an example. After the wall construction is completed, the ring beam concrete is poured to complete the flat opening and leveled with cement mortar. The straw roof panels with heat dissipation function brought into the construction site are hoisted on the wall in sequence. The water outlet joint 3 of the roof panel heat dissipation pipe of the first straw roof panel with heat dissipation function is connected with the water inlet joint 1 of the roof panel heat dissipation pipe of the second straw roof panel with heat dissipation function by hot-melt joints. According to this method, according to the design requirements, the water outlet joint 3 of the roof panel heat dissipation pipe of the second straw roof panel with heat dissipation function and the water inlet joint 1 of the roof panel heat dissipation pipe of the third straw straw roof panel with heat dissipation function are hot-melted. Way joints are connected until a c...

Embodiment 3

[0019] Embodiment 3: Take the winter heating of newly built single-storey houses in rural areas in the north as an example. The heat source of the heating system is in the form of a small water source heat pump, and the water supply temperature is 42°C. The rice straw roof panel with heat dissipation function is used for heating, and the indoor temperature is kept above 18°C. The indoor temperature is measured at heights of 0.5m, 1.0m, and 1.5m from the roof, and the temperature difference is 0.2-0.3°C, which is relatively small, so it is very comfortable to use this roof panel to achieve heating. The roof panel radiates from top to bottom to adjust the temperature, no wind or air flu, and the temperature is uniform. The heating system is set on the ceiling, which does not occupy the indoor space and the effective use area of the room, and the effect is excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com