Preparation method of lignin-based carbon nanofiber

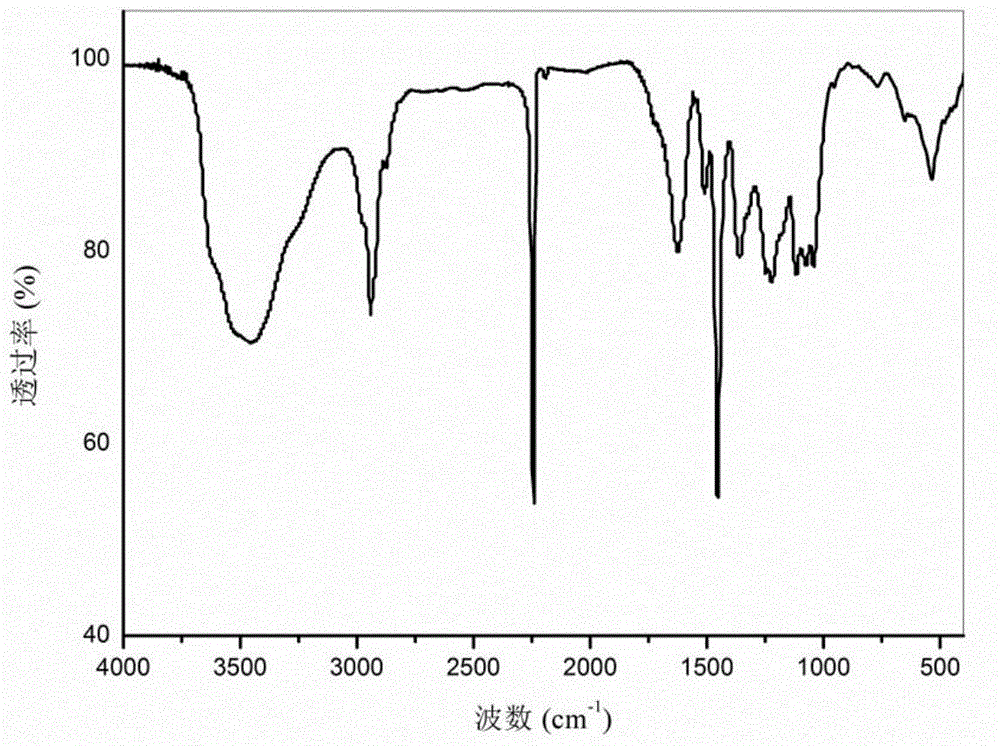

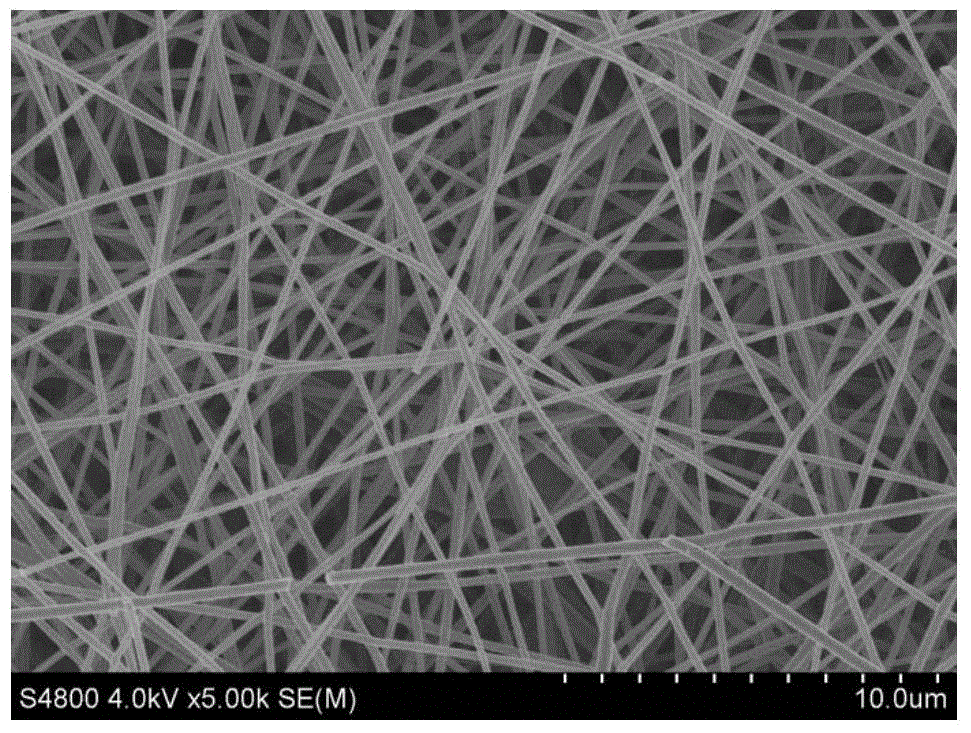

A carbon nanofiber, lignin-based technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of low CNF preparation efficiency, and achieve the effect of improving melting resistance and improving preparation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the preparation method of lignin-based carbon nanofibers comprises the following steps:

[0029] (1) Add dimethyl sulfoxide, lignin and acryloyl chloride sequentially in the reactor at a weight ratio of 100:30:30, stir the esterification reaction at 25°C for 1 hour, and add a small amount of triethylamine (TEA) after the reaction is completed Neutralize the HCl produced by the esterification reaction, then add ether to precipitate the modified lignin, then filter, wash with absolute ethanol several times, remove TEA hydrochloride, and obtain esterified lignin modified with acryloyl chloride;

[0030] (2) Add dimethylformamide, acryloyl chloride-modified esterified lignin, acrylonitrile, azobisiso Butyronitrile, carry out the homogeneous solution free radical copolymerization reaction at 60°C under the protection of nitrogen for 20 hours, remove the unreacted acrylonitrile monomer in the polymerization solution under vacuum after the reaction, and the...

Embodiment 2

[0036] In this embodiment, the preparation method of lignin-based carbon nanofibers comprises the following steps:

[0037] (1) Add dimethyl sulfoxide, lignin and acryloyl chloride sequentially in the reactor at a weight ratio of 100:30:20, stir the esterification reaction at 35°C for 1 hour, and add a small amount of triethylamine (TEA) after the reaction is completed Neutralize the HCl produced by the esterification reaction, then add ether to precipitate the modified lignin, then filter, wash with absolute ethanol several times, remove TEA hydrochloride, and obtain esterified lignin modified with acryloyl chloride;

[0038] (2) Add dimethyl sulfoxide, acryloyl chloride-modified esterified lignin, acrylonitrile, azobisiso Butyronitrile, under the protection of nitrogen, carry out homogeneous solution free radical copolymerization reaction at 65 ℃ for 18 hours, after the reaction is finished, remove the unreacted acrylonitrile monomer in the polymerization solution under vacu...

Embodiment 3

[0043] In this embodiment, the preparation method of lignin-based carbon nanofibers comprises the following steps:

[0044] (1) Add dimethyl sulfoxide, unmodified lignin and acryloyl chloride sequentially in the reactor at a weight ratio of 100:30:10, stir the esterification reaction at 25°C for 4 hours, and add a small amount of triethylamine after the reaction (TEA) to neutralize the HCl produced by the esterification reaction, then add ether to precipitate the modified lignin, then filter and wash with absolute ethanol several times to remove TEA hydrochloride to obtain esterified lignin modified with acryloyl chloride white;

[0045] (2) Add dimethylformamide, acryloyl chloride-modified esterified lignin, acrylonitrile, azobisiso Valeronitrile, carry out homogeneous solution free radical copolymerization reaction at 65°C under nitrogen protection for 20 hours, remove unreacted acrylonitrile monomer in the polymerization solution under vacuum after the reaction, and then s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com