High-strength steel with yield strength of 700MPa and TMCP manufacturing method

A technology of yield strength and manufacturing method, applied in the field of high-strength steel production, to achieve the effect of stable performance index and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

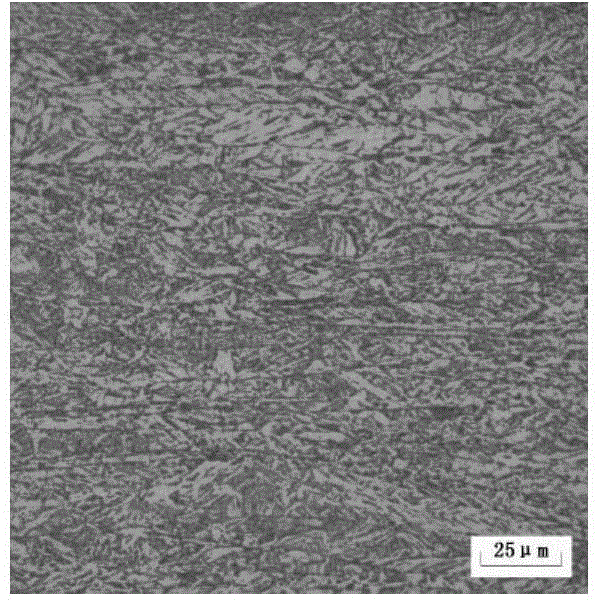

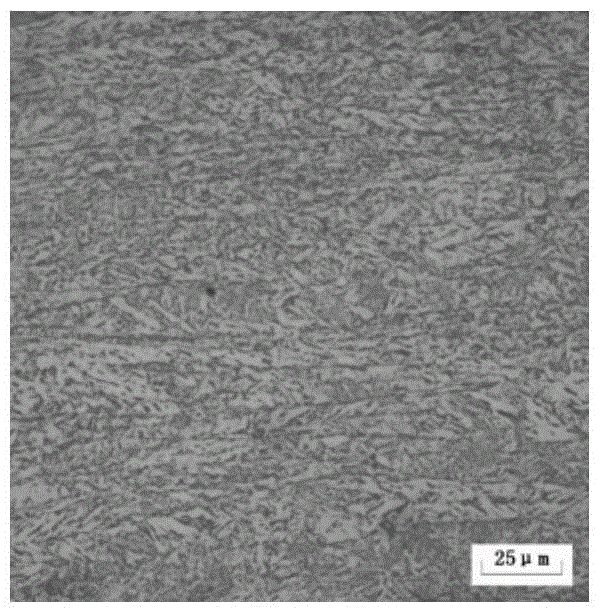

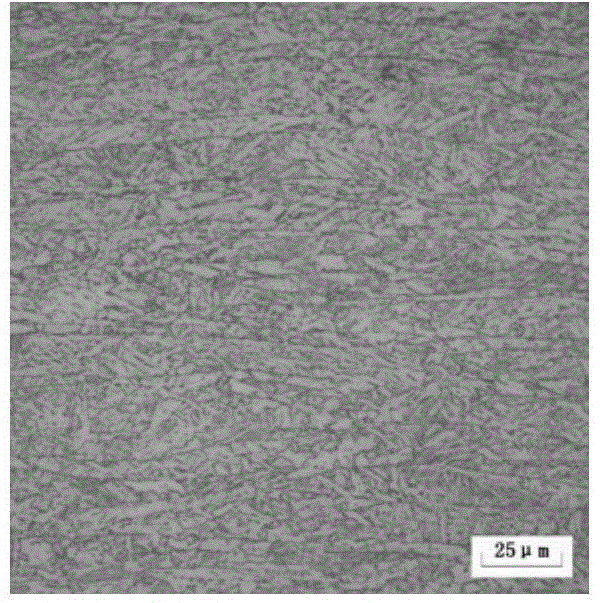

Image

Examples

Embodiment 1

[0031] According to the chemical composition range of the "700MPa grade construction machinery steel produced by the TMCP method" of the present invention, slab smelting, slab casting (slab specification: 250mm / 300mm×2000mm×L), Steel plate rolling (rolling specification: 20mm, 30mm).

[0032] A kind of yield strength 700MPa grade high-strength steel, the actual chemical composition (wt%) of embodiment is as shown in table 1:

[0033] Table 1 Actual chemical composition

[0034] Numbering C Si mn P S Alt V Nb Ti Ni Cr Mo B Ceq 1# 0.09 0.32 1.63 0.008 0.002 0.044 0.059 0.06 0.015 0.015 0.21 0.15 0.0016 0.44 2# 0.08 0.31 1.69 0.007 0.001 0.044 0.059 0.06 0.014 0.022 0.23 0.15 0.0016 0.43

[0035] Embodiment rolling process parameter is as shown in table 2:

[0036] Table 2 Actual rolling process parameters

[0037] Thickness / mm Temperature control thickness Finish rolling start temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com