Metallurgical slag waste heat recovery equipment and method

A technology for waste heat recovery equipment and metallurgical slag, applied in lighting and heating equipment, recycling technology, waste heat treatment, etc., can solve the problems of loss of water resources, environmental pollution, unutilized, etc., achieve efficient recycling and reduce water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

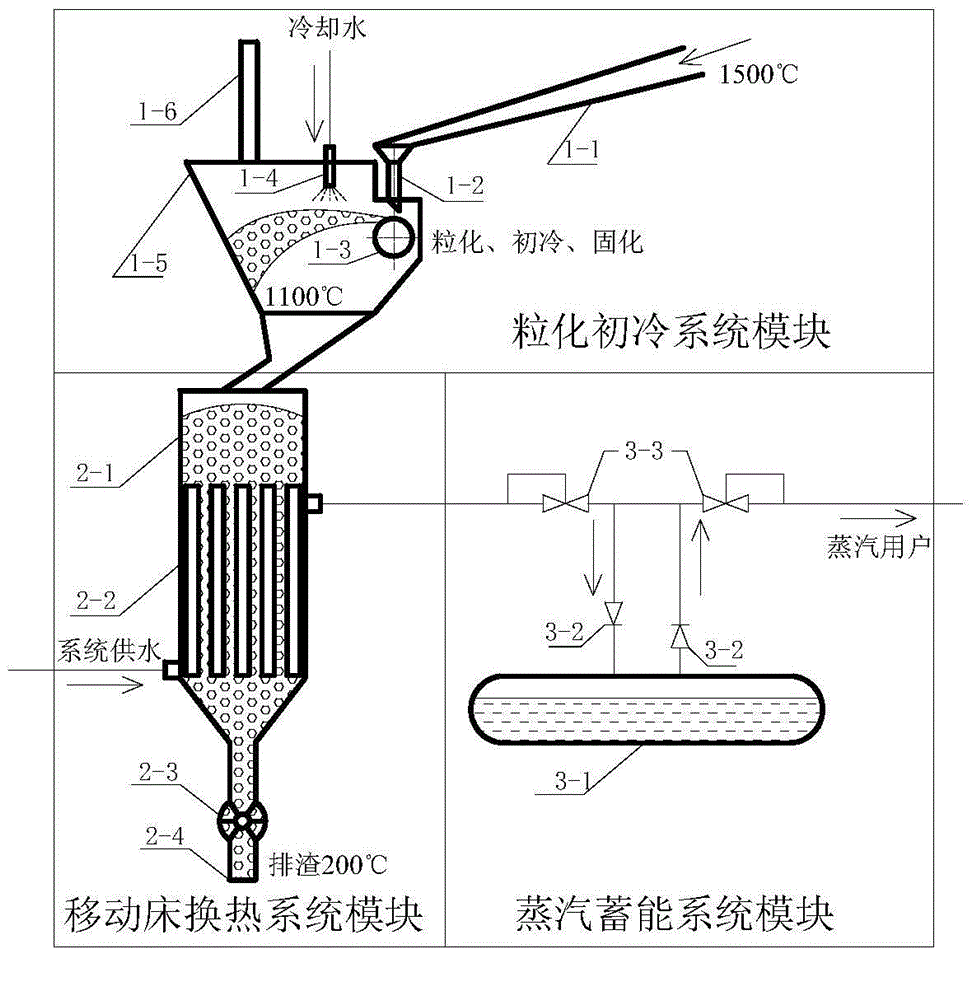

[0016] from figure 1 It can be seen from the figure that this metallurgical slag waste heat recovery equipment includes a granulation primary cooling system module and a moving bed heat exchange system module. The granulation primary cooling system module includes a metallurgical slag tank 1-1, a funnel feeder 1- 2. Granulation wheel 1-3, atomizer 1-4, granulation primary cooling box 1-5, moving bed heat exchange system module includes slag storage bin 2-1, moving bed heat exchanger 2-2, row Slag wheel 2-3; high-temperature molten metallurgical slag passes through the metallurgical slag tank, and is fed from top to bottom by the funnel feeder to the granulation wheel. The granulation wheel crushes the molten metallurgical slag and flies out along the tangential direction. During the flight, the slag contacts with the cooling water mist provided by the atomizer and undergoes water quenching to produce surface-solidified metallurgical slag particles and water vapor. The metallur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com