Earthy yellow raw glaze special for Nixing ceramics

A khaki-yellow, Nixing pottery technology, applied in the field of ceramic glazes, can solve the problems of thick glaze layer, contrary to the product concept, and the inability to highlight the beauty of pottery texture, etc., and achieve the effect of strong adhesion and freedom from worries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

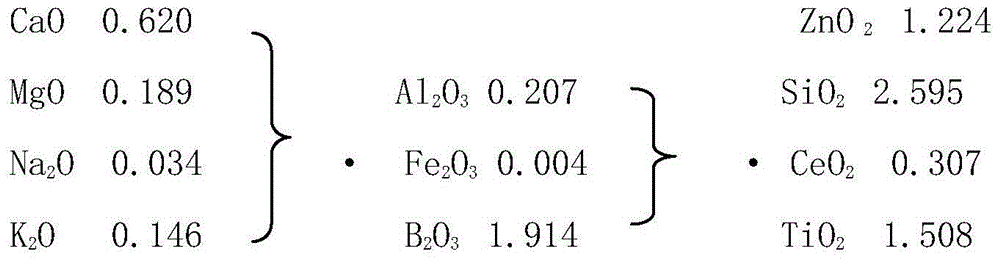

Method used

Image

Examples

Embodiment 1

[0013] Accurately weigh 36 grams of calcium borate, 5 grams of zirconium silicate, 6 grams of cerium oxide, 12 grams of zinc oxide, 14 grams of titanium dioxide, 9 grams of quartz, 12 grams of feldspar, 2 grams of limestone, and 4 grams of dolomite, mix them into the ball mill Add 80 grams of water and carry out ball milling for 45 minutes, ball: material ≈ 2: 1. After checking the fineness of the material, pass through a 200-mesh sieve and it will be stale. The aged raw material glaze is sprayed on the surface of the Nixing pottery body and fired at 1080°C.

[0014] According to the National Ceramic Quality Product Supervision and Testing Center (Jiangxi) in accordance with GB / T3532-2002 "Permissible Limits of Dissolution of Lead and Cadmium in Ceramic Products Contacting Food", the dissolution rate of lead and cadmium in this glaze is <0.1mg / L. The dissolution rate is <0.01mg / L, the national standard is lead dissolution rate 0.5mg / L, cadmium dissolution rate is 0.25mg / L, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com