A BNT-based lead-free electrostrictive material with luminescent properties and its preparation method

A technology of electrostrictive materials and luminescent properties, applied in the directions of luminescent materials, chemical instruments and methods, etc., to achieve the effects of simple production process, excellent luminescent properties, and excellent fatigue resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

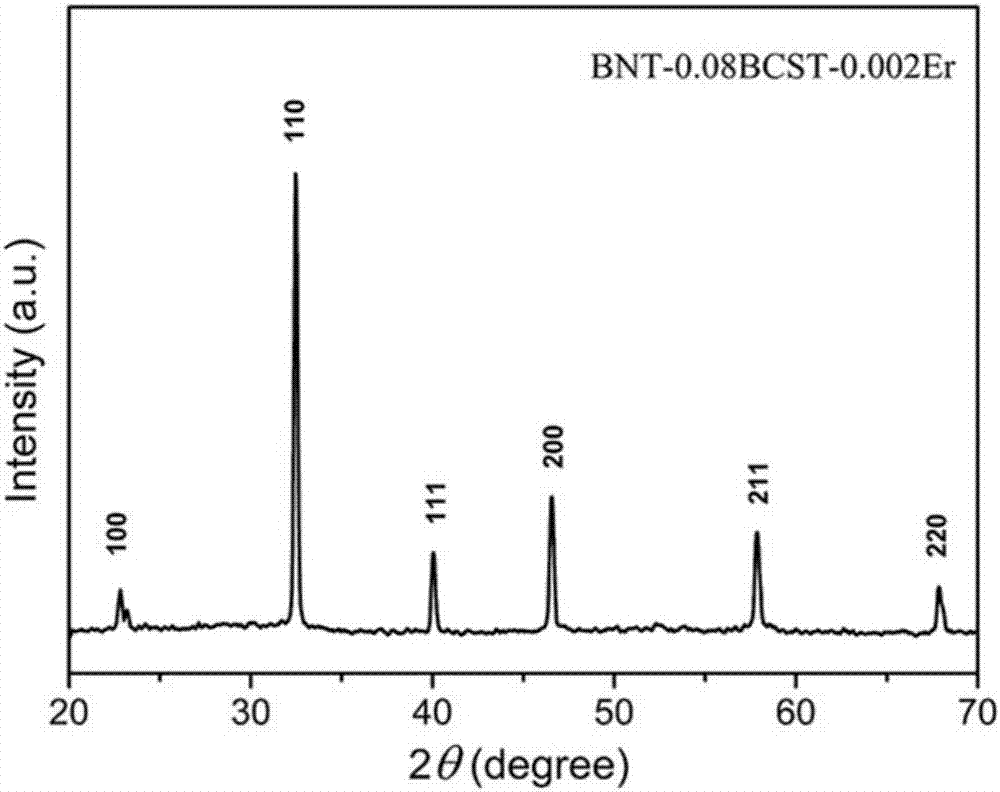

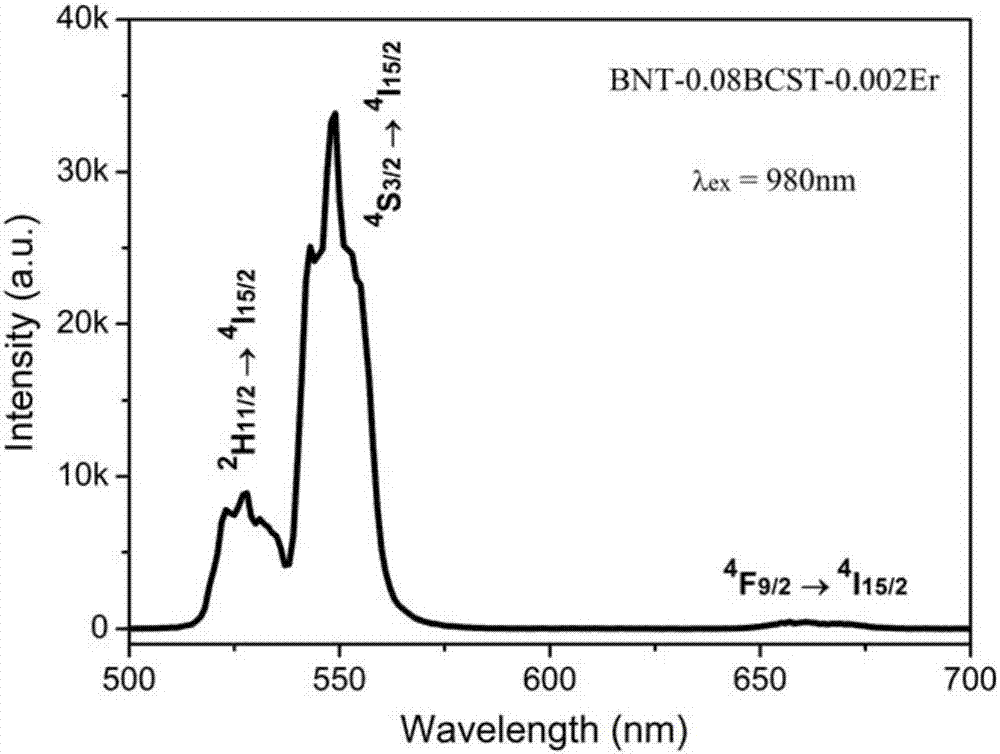

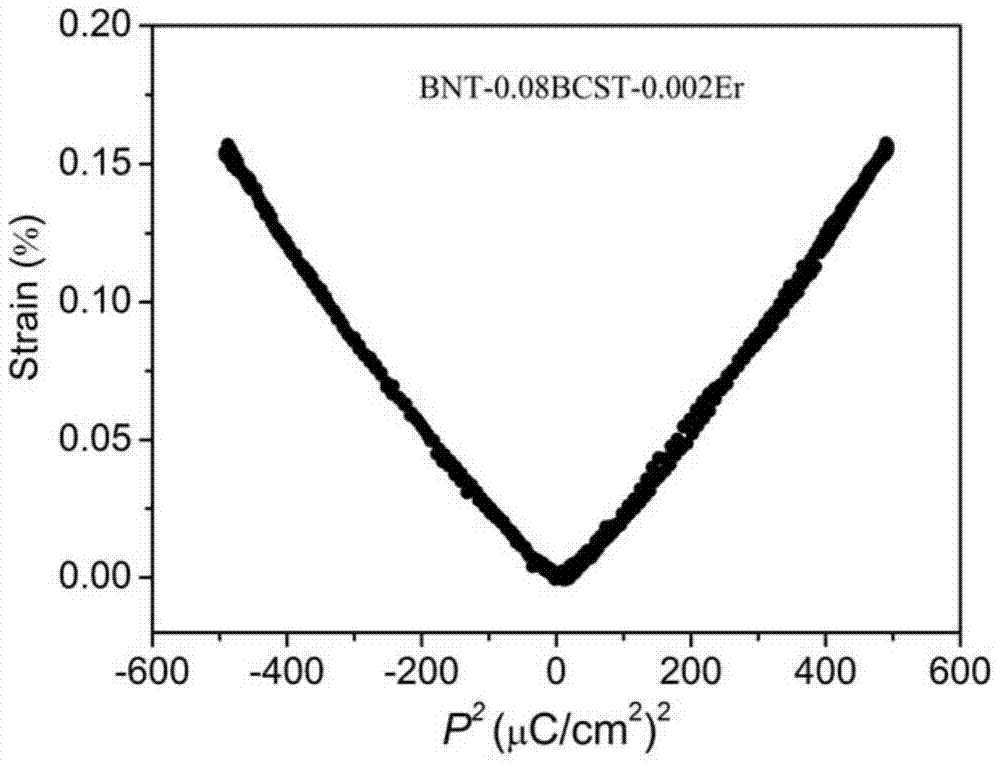

[0071] The preparation chemical general formula is (1-x) (Bi 0.5 Na 0.5 )TiO 3 The BNT-based lead-free luminescent electrostrictive material of -xM-yR, wherein, M=(Ba 0.90 Ca 0.10 )(Ti 0.92 sn 0.08 )O 3 , R=Er, x=0.08, y=0.002, 0.004, 0.006, 0.008, 0.010.

[0072] By Bi 2 o 3 、Na 2 CO 3 、TiO 2 、BaCO 3 , CaCO 3 , SnO 2 and Er 2 o 3 (analytical pure) is raw material, by 0.92 (Bi 0.5 Na 0.5 )TiO 3 -0.08 (Ba 0.90 Ca 0.10 )(Ti 0.92 sn 0.08 )O 3 - The stoichiometric ratio (molar ratio) of Bi, Na, Ti, Ba, Ca, Sn and Er in yEr (y=0.002, 0.004, 0.006, 0.008, 0.010) Weigh the raw materials, use absolute ethanol as the medium and use ZrO 2 The balls are milled in a ball mill jar for 24 hours, wherein, the ball milling speed is 150-200 rpm, the mass ratio of the added zirconia balls to the ball abrasive is 1.5:1, and the mass ratio of the added anhydrous ethanol to the ball mill is 2.0:1. Then, dry, press into blocks and place in a closed Al 2 o 3 Crucible, pre...

Embodiment 2

[0077] The preparation chemical general formula is (1-x) (Bi 0.5 Na 0.5 )TiO 3 The BNT-based lead-free luminescent electrostrictive material of -xM-yR, wherein, M=(Ba 0.90 Ca 0.10 )(Ti 0.92 sn 0.08 )O 3 , R=Pr, x=0.08, y=0.002, 0.004, 0.006, 0.008, 0.010.

[0078] By Bi 2 o 3 、Na 2 CO 3 、TiO 2 、BaCO 3 , CaCO 3 , SnO 2 and Pr 6 o 11 (analytical pure) is raw material, by 0.92 (Bi 0.5 Na 0.5 )TiO 3 -0.08 (Ba 0.90 Ca 0.10 )(Ti 0.92 sn 0.08 )O 3 - The stoichiometric ratio (molar ratio) of Bi, Na, Ti, Ba, Ca, Sn and Pr in yPr (y=0.002, 0.004, 0.006, 0.008, 0.010) Weigh the raw materials, use absolute ethanol as the medium and use ZrO 2 The balls are milled in a ball mill jar for 24 hours, wherein, the ball milling speed is 150-200 rpm, the mass ratio of the added zirconia balls to the ball abrasive is 1.5:1, and the mass ratio of the added anhydrous ethanol to the ball mill is 2.0:1. Then, dry, press into blocks and place in a closed Al 2 o 3 Crucible, pr...

Embodiment 3

[0081] The preparation chemical general formula is (1-x) (Bi 0.5 Na 0.5 )TiO 3 - The BNT-based lead-free luminescent electrostrictive material of xM-yR, wherein, M=BaTiO 3, R=Er, x=0.07, y=0.002, 0.004, 0.006, 0.008, 0.010.

[0082] By Bi 2 o 3 、Na 2 CO 3 、TiO 2 、BaCO 3 and Er 2 o 3 (analytical pure) is raw material, by 0.92 (Bi 0.5 Na 0.5 )TiO 3 -0.07BaTiO 3 - The stoichiometric ratio (molar ratio) of Bi, Na, Ti, Ba and Er in yEr (y=0.002, 0.004, 0.006, 0.008, 0.010) Weigh the raw materials, use absolute ethanol as the medium and use ZrO 2 The balls are milled in a ball mill jar for 24 hours, wherein, the ball milling speed is 150-200 rpm, the mass ratio of the added zirconia balls to the ball abrasive is 1.5:1, and the mass ratio of the added anhydrous ethanol to the ball mill is 2.0:1. Then, dry, press into blocks and place in a closed Al 2 o 3 Crucible, pre-fired at 850 ° C for 4 h, and then put the pre-fired powder back into the ball mill jar, using abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com