Manufacturing method and application of ecological straw brick or ecological straw ball

A manufacturing method, a technology of straw bricks, applied in the field of comprehensive utilization of natural resources, to achieve the effects of increasing income, improving the ecological environment of river banks, and having a large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

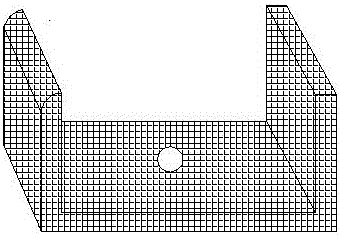

[0059] The mixture of wheat straw and rice straw was used as raw material to make ecological straw bricks, which was applied to an ecological slope protection project in Taihu Lake area. The manufacturing and engineering application process of ecological straw bricks are as follows: (1) Put the collected straw into a pulverizer and crush it into 1.0cm granular matter; (2) Add 3% of the straw mass to the crushed straw particles Copper isooctanoate and 50% quicklime are fermented with water for 12 days, among which the materials are turned once on the sixth day and the ninth day to become the required straw grains; (3) Straw grains, cement, water reducing agent, crushed stone, Put the self-made green additive and water into the mixer according to the mass ratio of 150:100:1.5:400:3:60 and stir evenly. (4) Pour the mixed material into the pre-produced mold in the factory to make such figure 1 Bricks of the shape shown. (5) After curing for 8 hours under the conditions of temper...

Embodiment 2

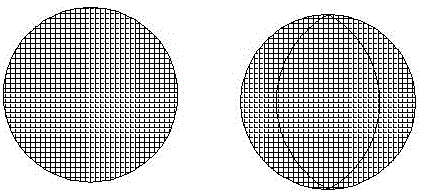

[0061] The mixture of wheat straw and rice straw was used as raw material to make ecological straw balls and applied to an ecological gabion project in Taihu Lake area. The manufacturing and engineering application process of ecological straw balls are as follows: (1) put the collected straw into a pulverizer, and pulverize it into 1.0cm granular matter. (2) Add 3% copper isooctanoate and 50% quicklime to the crushed straw granules, add water and ferment for 12 days, and turn the materials once on the fourth and eighth days to become the required straw granules . (3) Put straw grains, cement, water reducing agent, gravel, self-made green additives and water into the mixer at a mass ratio of 150:100:1.5:400:3:60 and stir evenly. (4) Pour the mixed material into the pre-produced mold in the factory to make such image 3 The shapes shown are pellets with a diameter of 10 cm. (5) After curing for 6 hours under the conditions of temperature 25 oC and humidity 50%, take off the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com