Efficient anaerobic fermentation device for straw feed and application method thereof

An anaerobic fermentation, straw feed technology, applied in feed, application, food science and other directions, can solve the problems of incapable of industrialized production of animal basic feed, incapable of industrialized perennial production, uneven fermentation temperature, etc. The effect of lifting and lowering more smoothly and increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

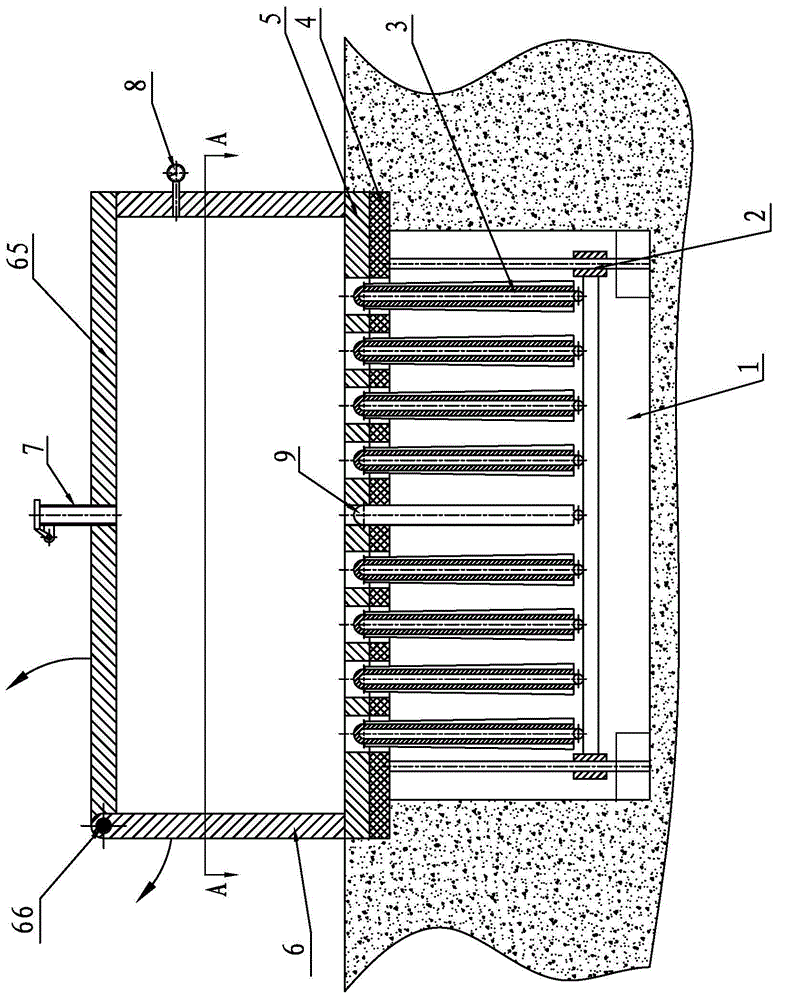

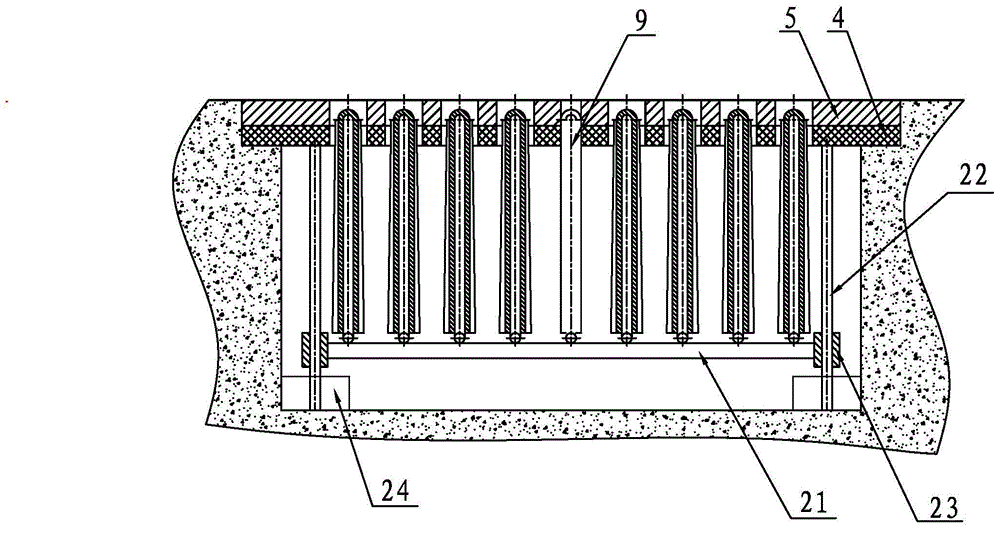

[0042] Embodiment 1: A kind of straw feed quick-acting anaerobic fermentation equipment, such as Figure 1-7 As shown, it consists of a supporting seat pit 1, a synchronous lifting mechanism 2, a guide heat transfer component 3, a heat insulation layer 4, a steel bottom plate 5, a heat preservation fermentation box 6, a pressurized exhaust pipe 7, a side temperature sensor 8 and The core temperature sensor 9 is composed of a steel bottom plate 5 and a heat insulation layer 4 arranged on the upper opening of the support seat pit 1 in sequence, and a heat transfer component 3 and a core are arranged on the steel bottom plate 5 and the heat insulation layer 4 to facilitate guiding. The guide hole for the upper and lower temperature measuring sensors 9, the synchronous lifting mechanism 2 is set in the support seat pit 1, and is located under the heat insulation layer 4, and the guiding heat transfer part 3 and the core temperature measuring sensor 9 are inserted into the steel bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com