A method for harmless treatment of arsenic-containing sludge

A technology for harmless treatment of arsenic sludge, applied in oxidation treatment of sludge, chemical instruments and methods, sludge treatment, etc., can solve the problem of low solidification rate, achieve low roasting temperature, low temperature, and improve solidification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

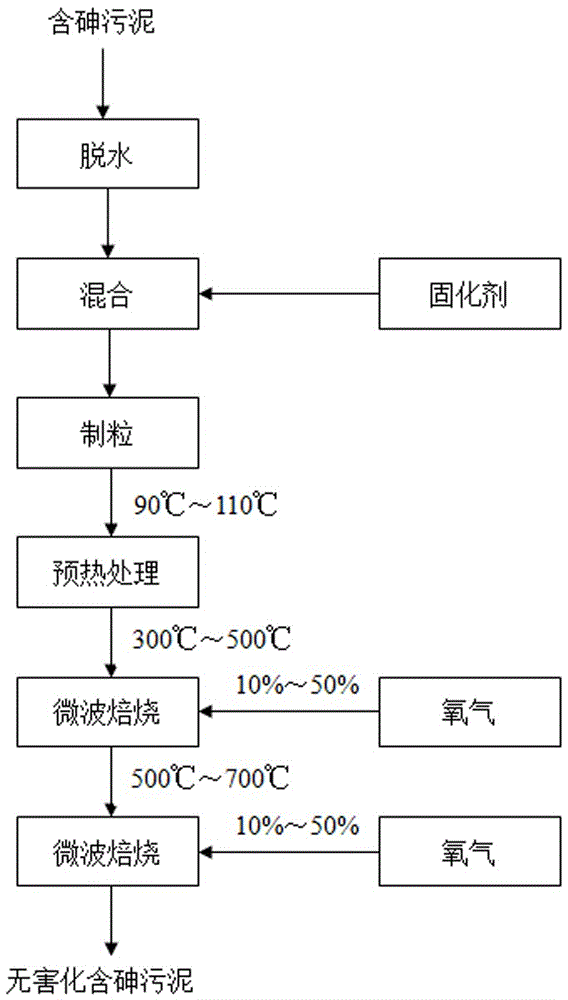

Image

Examples

Embodiment 1

[0041] (1) Sludge pre-treatment: first dehydrate the arsenic-containing sludge to make the moisture content of the arsenic-containing sludge 60%.

[0042] (2) Material mixing: Mix 500g of arsenic-containing sludge in step (1) with 25g of fly ash evenly, and then make particles with a diameter of 0.5-1.5cm.

[0043] (3) Sludge preheating treatment: Under normal pressure, use microwaves to pretreat and heat the sludge particles treated in step (2) for 5 minutes, and the heating temperature is 100°C.

[0044] (4) One-stage microwave oxidation roasting: Under normal pressure, control the material treated in step (3) to 300°C for 30 minutes, and feed 10% oxygen. This process oxidizes trivalent arsenic in the sludge into pentavalent arsenic.

[0045] (5) Two-stage microwave oxidation roasting: Under normal pressure, 10% oxygen is continuously introduced, and the material treated in step (4) is brought to a temperature of 500°C and kept for 40 minutes. for further oxidative decompo...

Embodiment 2

[0048] (1) Sludge pretreatment: first, dehydrate the arsenic-containing sludge to make the moisture content of the arsenic-containing sludge 60-70%.

[0049] (2) Material mixing: Mix 500g of arsenic-containing sludge and 50g of fly ash in step (1) evenly, and then make particles with a diameter of 0.5-1.5cm.

[0050] (3) Sludge preheating treatment: Under normal pressure, use microwaves to pretreat and heat the sludge particles treated in step (2) for 5 minutes, and the heating temperature is 100°C.

[0051] (4) One-stage microwave oxidation roasting: Under normal pressure, control the material treated in step (3) to 350°C for 25 minutes, and feed 20% oxygen. This process oxidizes trivalent arsenic in the sludge into pentavalent arsenic.

[0052] (5) Two-stage microwave oxidation roasting: Under normal pressure, continuously feed 20% oxygen, bring the material treated in step (4) to a temperature of 550°C, and keep it warm for 35 minutes. for further oxidative decomposition. ...

Embodiment 3

[0055] (1) Sludge pretreatment: first, dehydrate the arsenic-containing sludge to make the moisture content of the arsenic-containing sludge 60-70%.

[0056] (2) Material mixing: Mix 500g of arsenic-containing sludge in step (1) with 100g of fly ash evenly, and then make particles with a diameter of 0.5-1.5cm.

[0057] (3) Sludge preheating treatment: Under normal pressure, use microwaves to pretreat and heat the sludge particles treated in step (2) for 5 minutes, and the heating temperature is 100°C.

[0058] (4) One-stage microwave oxidation roasting: Under normal pressure, control the material treated in step (3) to 400 ° C for 20 minutes, and feed 30% oxygen. This process oxidizes trivalent arsenic in the sludge into pentavalent arsenic.

[0059] (5) Two-stage microwave oxidation roasting: Under normal pressure, continuously feed 30% oxygen, bring the material treated in step (4) to a temperature of 600°C, and keep it warm for 30 minutes. for further oxidative decomposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com