Assembly structure for a metal decorating part of mobile phone front shell and processing and assembling method thereof

A metal decoration and assembly structure technology, applied to the structure of telephones, etc., can solve the problems of inaccurate bending angles of stamping parts, easy springback at bending parts, and delamination at disconnected parts, so as to improve the appearance effect and avoid gaps Too large to avoid the effect of delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

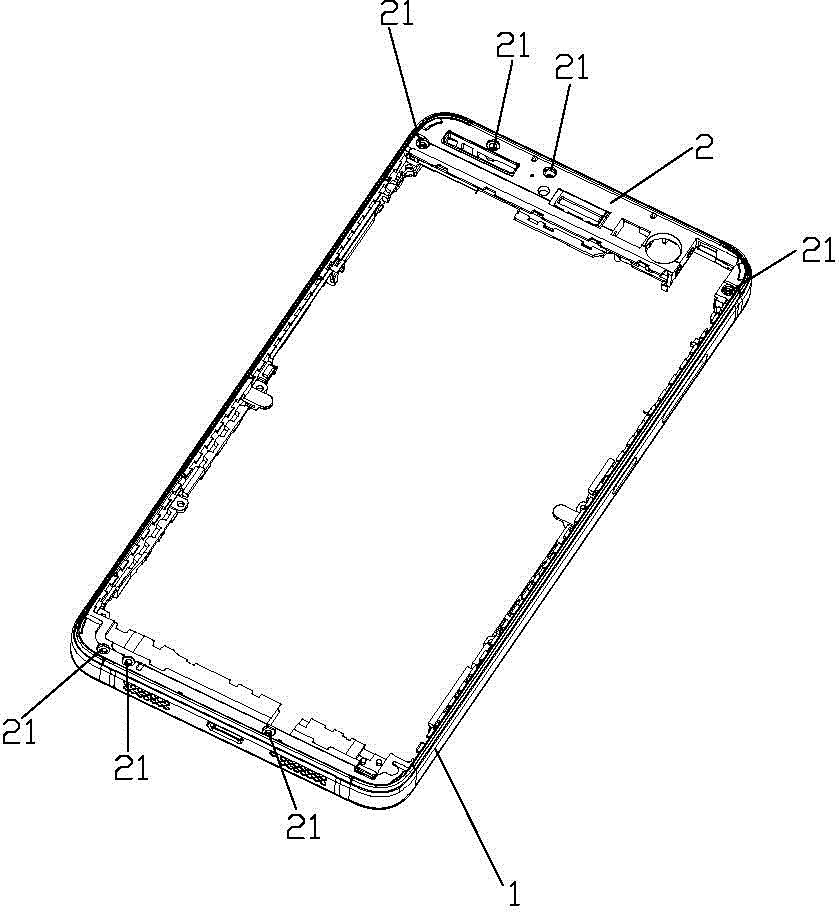

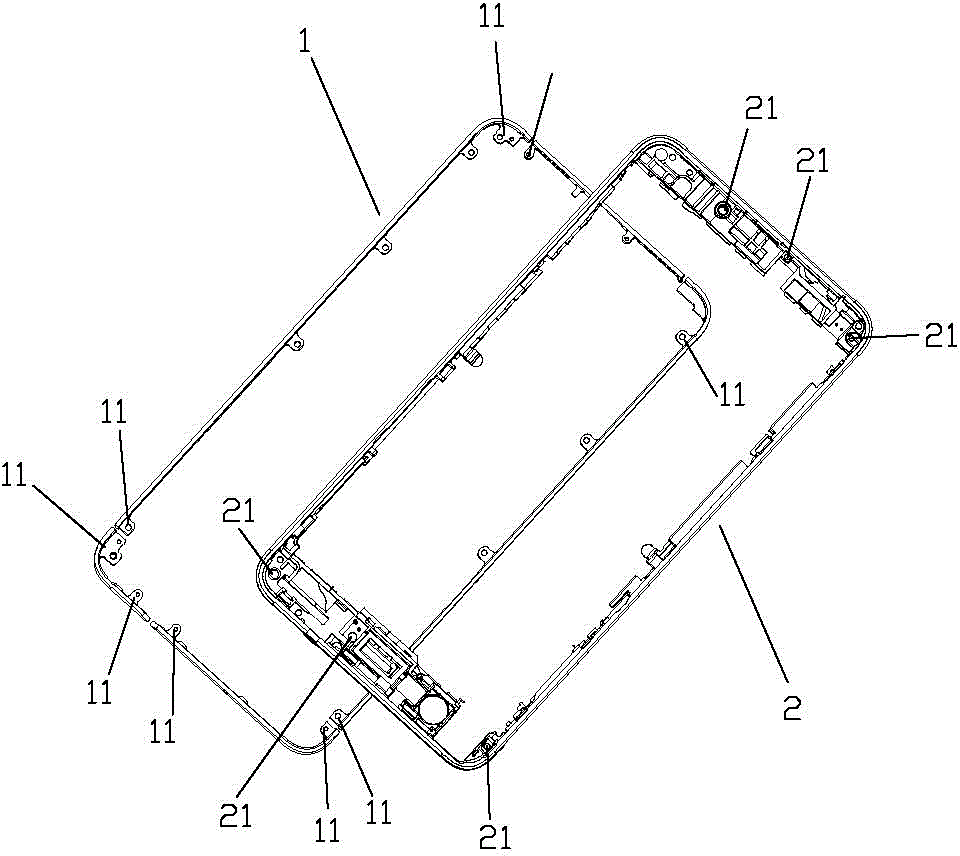

[0039] The present invention is used for the assembly structure of the metal decoration of mobile phone front case, as Figure 1 to Figure 4 As shown, it includes an aluminum alloy frame 1 and a plastic 2 fixed on the inner wall of the aluminum alloy frame 1. The aluminum alloy frame 1 is made of an aluminum alloy plate through CNC processing, and the four bending corners of the aluminum alloy frame 1 are all set The corners are bent in a circular arc shape, and the inner wall of the aluminum alloy frame 1 is bonded and fixed to the plastic 2 . The aluminum alloy frame 1 processed by CNC has a good shape, and the arcs of the four bending corners of the aluminum alloy frame 1 will not spring back, so there is no gap between the metal decorative parts and the plastic 2. The gap can be better bonded and fixed with the plastic 2.

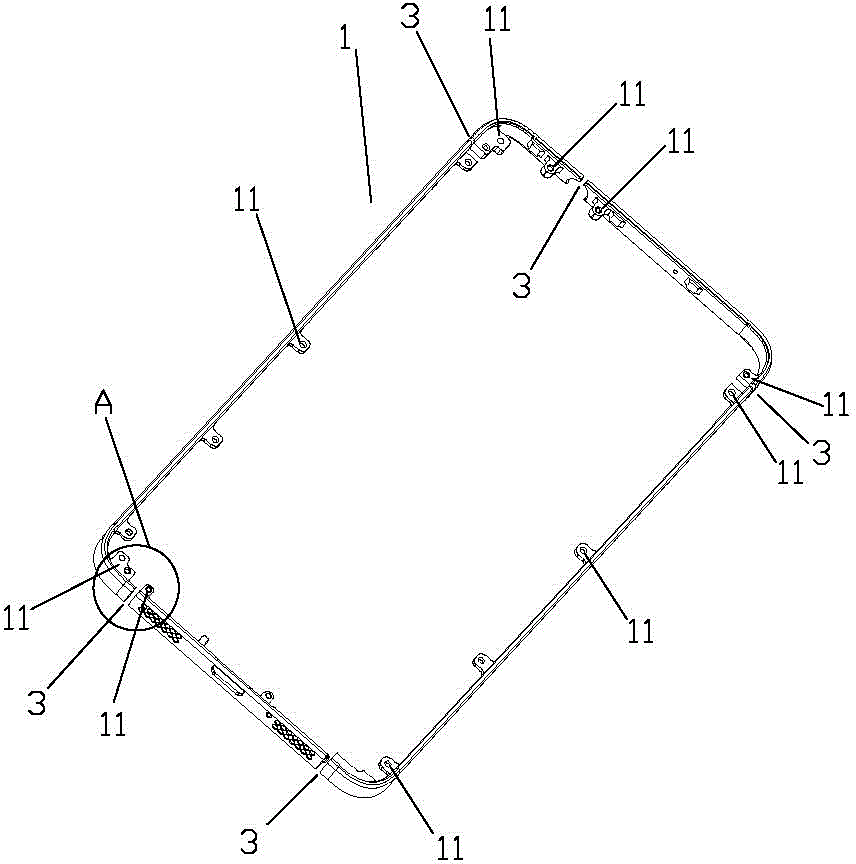

[0040] The aluminum alloy frame 1 is divided into multiple sections, and the inner wall of the aluminum alloy frame 1 located at the split point 3 is ...

Embodiment 2

[0044] The processing and assembling method for the assembly structure of the metal decoration of the mobile phone front shell of the present invention, such as figure 1 To such as image 3 shown, including the following steps:

[0045] (1) Clamp fixation:

[0046] Fix the aluminum alloy plate through the clamp;

[0047] (2) CNC processing:

[0048] According to the drawing, the aluminum alloy frame 1 that is consistent with the internal structure of the front shell of the mobile phone and has four arc-shaped bending corners is processed by CNC step by step;

[0049] (3) Split into segments:

[0050] The aluminum alloy frame 1 is divided into segments, and the inner wall of each division 3 of the aluminum alloy frame 1 and the surrounding of the inner wall of the aluminum alloy frame 1 are formed with screw columns 11 by CNC machining;

[0051] (4) Dispensing and bonding:

[0052] The aluminum alloy frame 1 is located at the split point 3 and the screw column 11 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com