Production method and application of vanadium cell electrolyte crystal

A production method and electrolyte technology, applied in the direction of fuel cells, regenerative fuel cells, electrochemical generators, etc., to achieve the effects of saving freight, reducing transportation costs, and reducing transportation weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

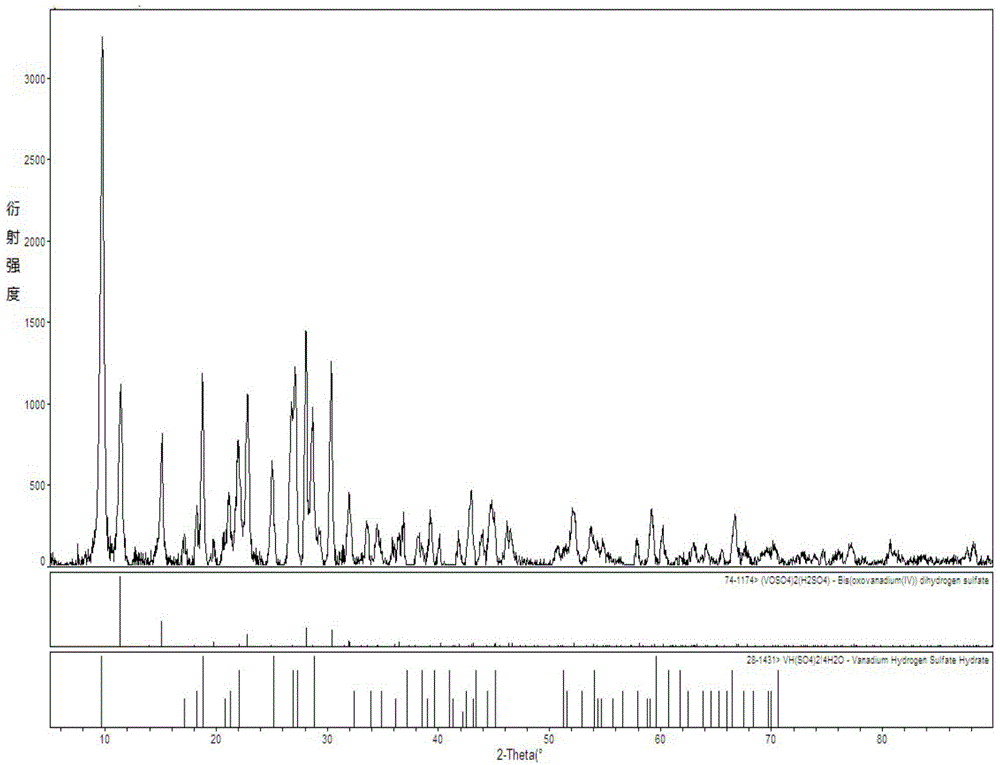

[0039] Add 300g vanadium sulfate (V 2 (SO 4 ) 3 10H 2 O), 265g vanadyl sulfate (VOSO 4 ·5H 2 (2), 260g concentrated sulfuric acid (98%), stir well and keep the temperature at 90°C, continue to stir for 10h, cool to room temperature and continue to stir for 5h, the material is initially liquid, and gradually solidifies into powder, and the powder is detected, and the main components are: V 11%, V 3+ 5.45%, V 3+ / VO 2+ =0.98, SO 4 2- 56.8%, the rest is water. Sampling is carried out XRD analysis, obtains XRD pattern such as figure 1 . from figure 1 It can be seen that the crystals have been acidified by concentrated sulfuric acid, and the original sulfate crystals have been transformed into trivalent and tetravalent vanadium-containing double salt crystals of sulfuric acid.

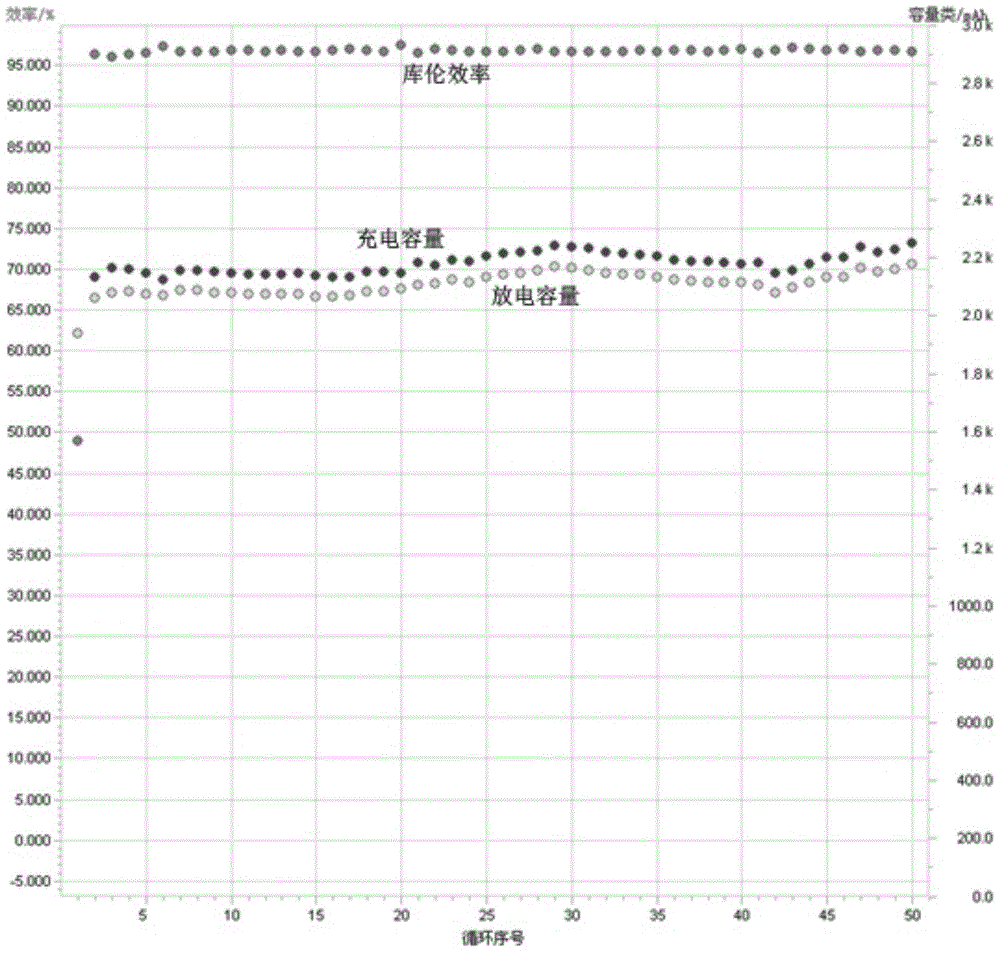

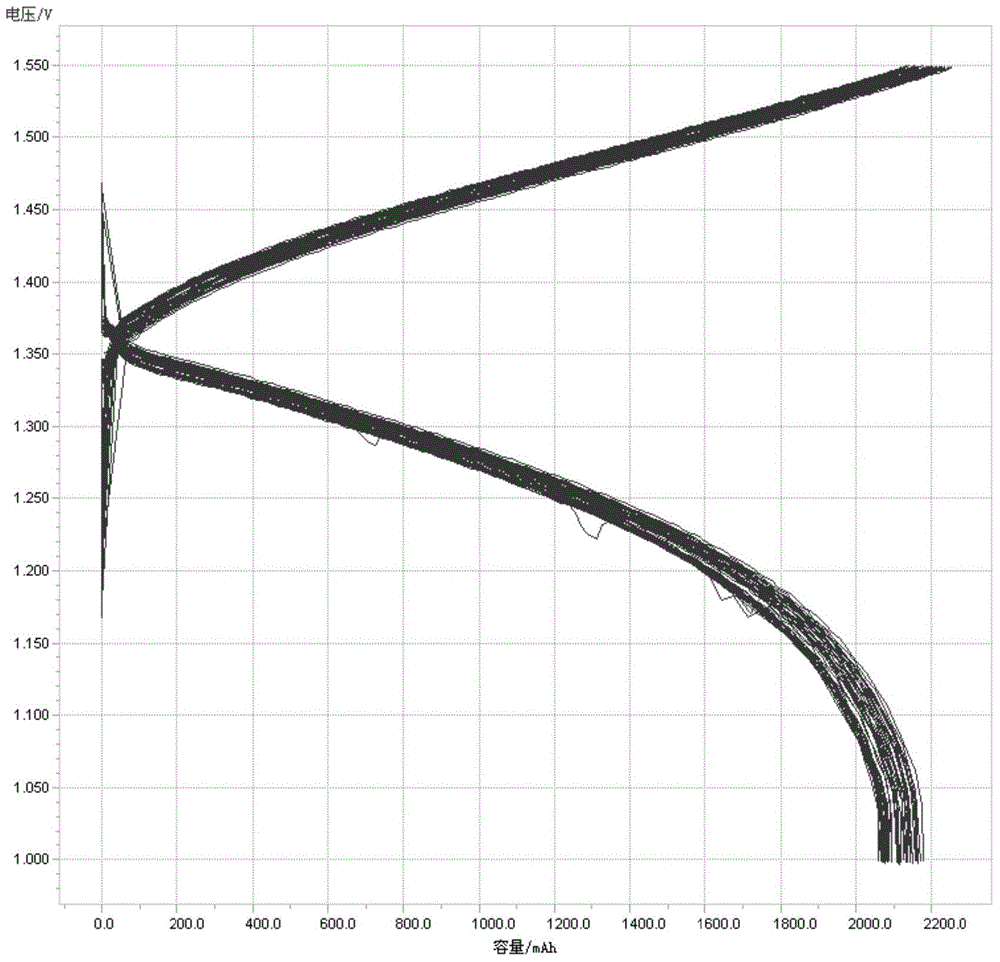

[0040] Take 500g of the above electrolytic liquid crystal, add 350ml of water, heat to 100°C, stir for 2h, and all the crystals are dissolved. The liquid was fixed to 650ml to obtain an electr...

Embodiment 2

[0045] Add 250g vanadium sulfate (VSO 4 ·7H 2 O), 750g vanadyl sulfate (VOSO 4 ·5H 2 (0), 660g concentrated sulfuric acid, stir evenly, and maintain 100 ℃, continue to stir for 5h, cool to room temperature and continue to stir for 10h, the material is gradually solidified into powder by liquid; detection powder, composition is: V 10.4%, V 3+ 6.15%, V 3+ / VO 2+ = 1.02, SO 4 2- 53%, the rest is water.

[0046] Take 800g of the above electrolytic liquid crystal, add 500ml of water, heat to 100°C, stir for 2 hours, and all the crystals are dissolved. The liquid was fixed to 800ml to obtain an electrolyte solution in which the average vanadium valence state was 3.47, the vanadium was 2 mol / l, and the sulfate radical was 5.2 mol / l.

[0047] The dissolved solution is divided into two parts, which are loaded into the positive and negative electrodes of the battery respectively, activated by the initial charge, and used for the battery charge and discharge cycle.

Embodiment 3

[0049] (1) Crystal production

[0050] negative crystal

[0051] Get 200g vanadium sulfate (V 2 (SO 4 ) 3 .10H 2 (0) add 75g 98% concentrated sulfuric acid, the mass ratio of vanadium sulfate and concentrated sulfuric acid is 2.67, stir evenly, maintain reaction temperature 60 ℃, continue to stir 8h, be cooled to room temperature and continue to stir 10h, material is solidified into green powder gradually by liquid state. Sampling and testing the powder, the main components are V 13.01%, V 3+ / V99.7%, SO 4 2- 63.47%, the rest is water.

[0052] Positive crystal

[0053] Get 178g vanadyl sulfate (VOSO 4 ·5H 2 (0) powder, add 105g 98% concentrated sulfuric acid, stir evenly, maintain reaction temperature 90 ℃ and continue to stir for 5h, be cooled to room temperature and continue to stir for 8h, material is solidified into green powder gradually by muddy state. Sampling and testing the powder, the main components are V 12.68%, VO 2+ / V 99.8%, SO 4 2- 61%, the rest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com