Automatic focusing microscope based on eccentric beam method and focusing method thereof

An autofocus and beam method technology, applied in the field of microscope focusing, can solve the problems of uneven light intensity distribution of light source, errors, poor autofocus effect, etc., to eliminate uneven light intensity distribution of light spots, strong anti-noise ability, and accurate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

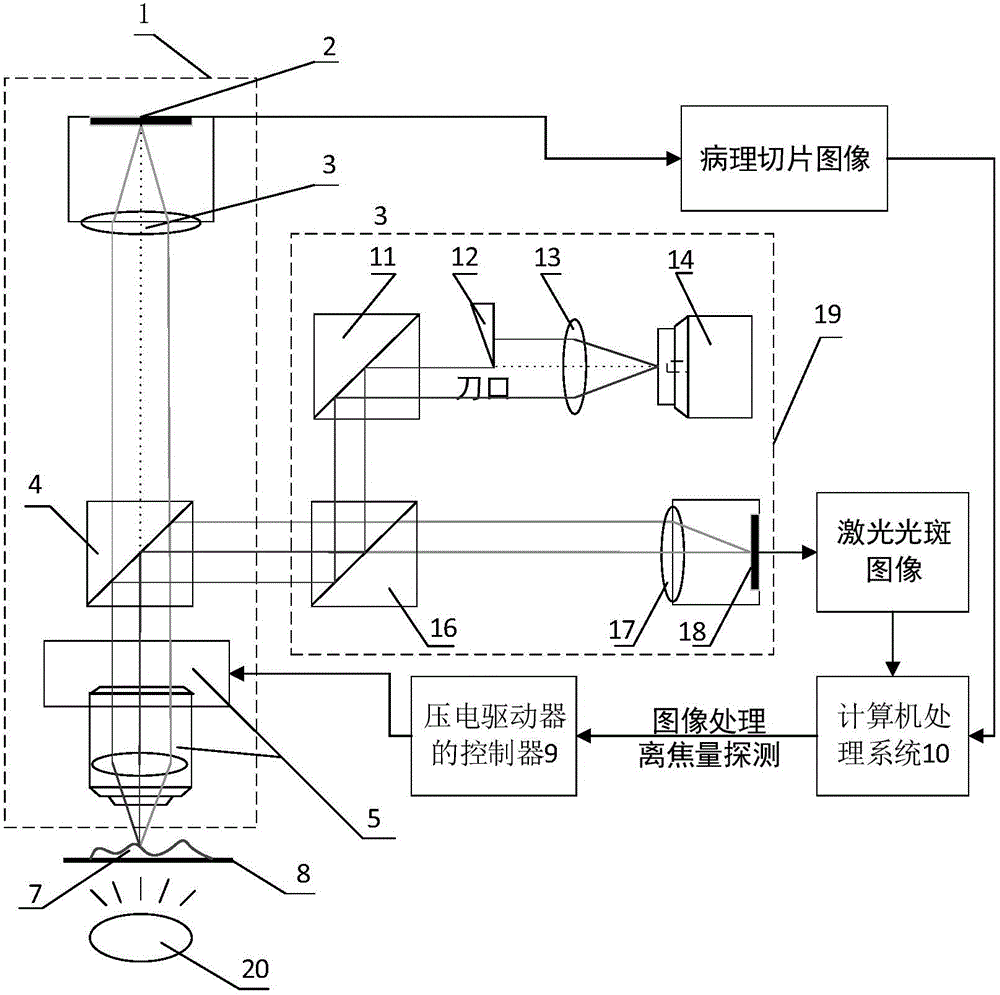

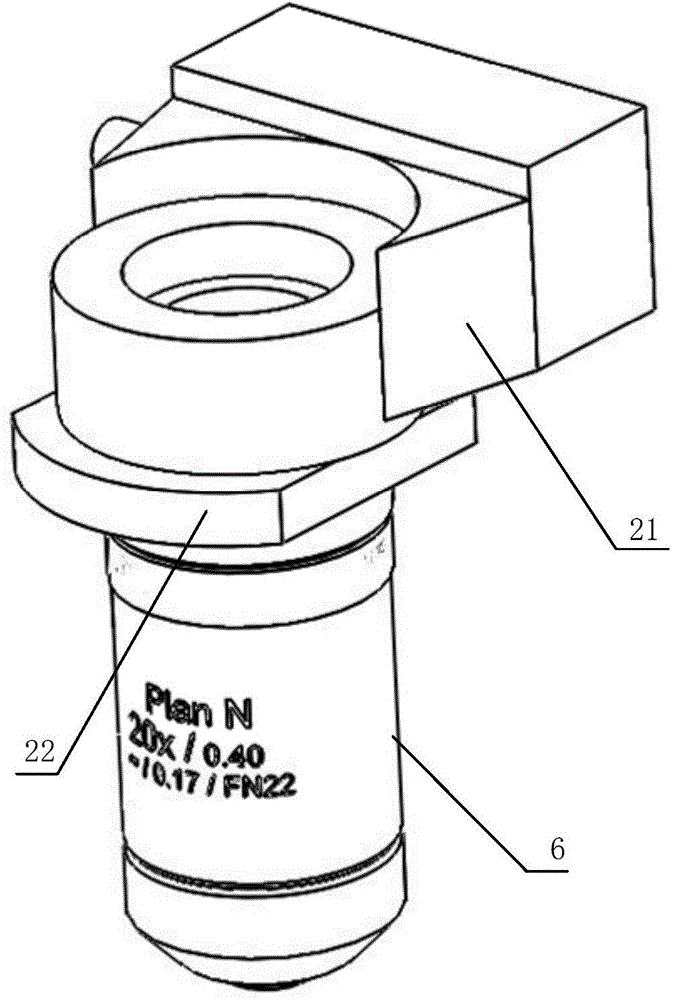

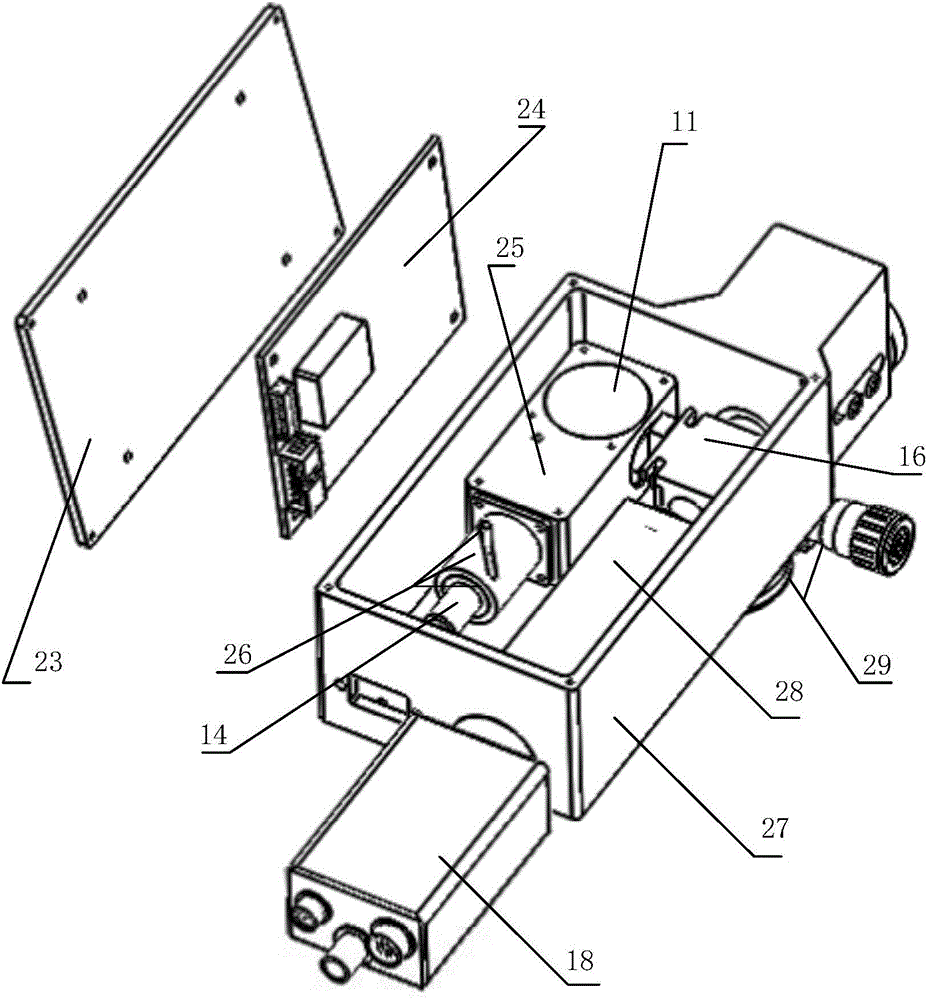

[0062] This embodiment provides an autofocus microscope based on the eccentric beam method and its focusing method.

[0063] The autofocus microscope based on the eccentric beam method, its hardware composition includes an autofocus device and an XY stage, and the autofocus device includes an eccentric beam defocus detection module, a microscopic imaging module, and a piezoelectric objective lens driver; the eccentric The beam defocus detection module is used to emit an eccentric laser beam to irradiate the sample surface, and obtain the reflected semicircular spot image, and its radius is linearly related to the sample defocus; the XY stage is used to move the sample to realize the scanning movement of the sample; the microscopic imaging module is used to obtain a clear sample image after focusing; the piezoelectric objective lens driver is used to compensate the defocus amount of the current field of view to complete the focusing.

[0064] The autofocus device also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com