Method for adjusting water squeezing or acid squeezing through water or acid squeezing roller device for raw foil machine

A raw foil machine, reverse adjustment technology, applied in the electrolysis process, electroforming and other directions, can solve the problems of too loose or too tight lamination, troublesome adjustment, damage to the surface of the cathode roller, etc., to increase speed and accuracy, reduce Production cost, the effect of avoiding crush injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

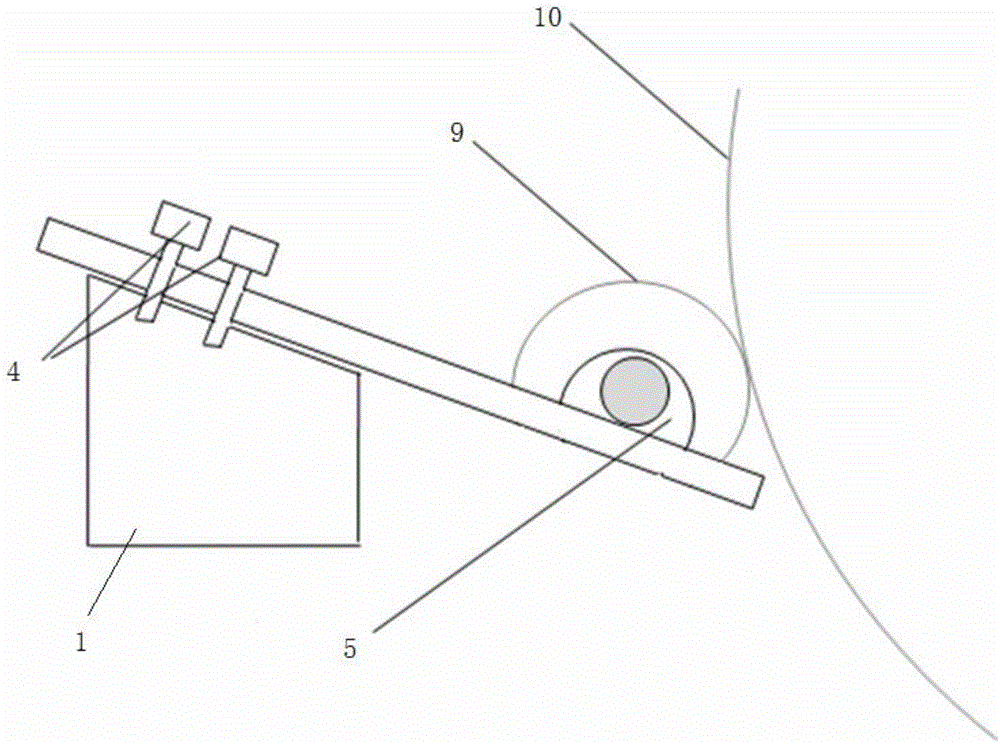

[0028] see above figure 1 , which shows a prior art squeezing or acid roller, including a bracket 1, a set screw 4, a bearing seat 5, a squeezing or acid roller 9 close to the cathode 10, and a rigid press fit between the pressure roller and the cathode roller.

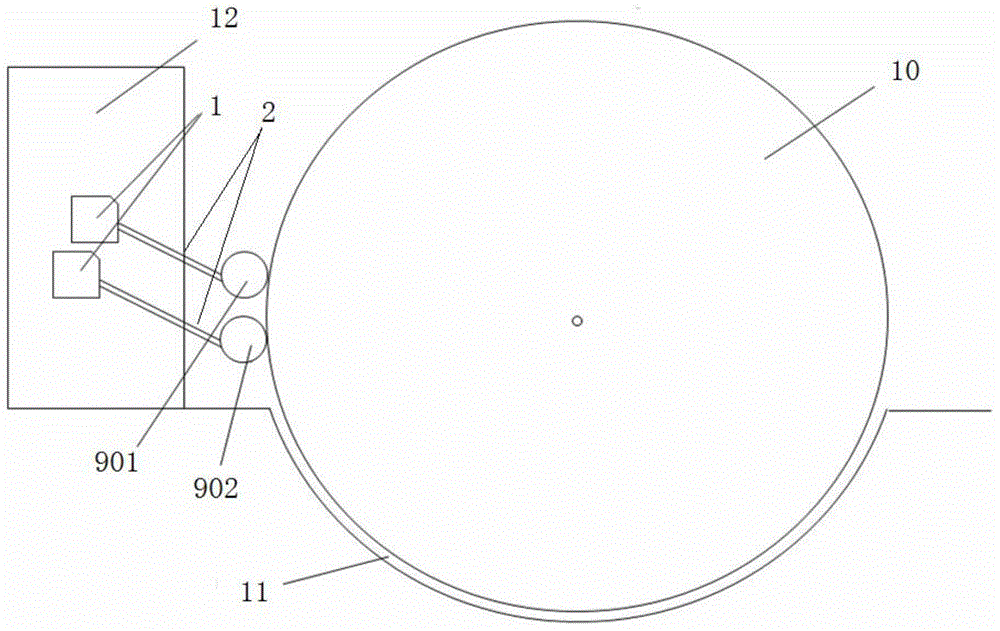

[0029] figure 2 Shows the positional relationship between water squeezing or acid rollers 901, 902, cathode roller 10, and electrolytic cell 11, wherein the bracket 1 is fixed on the winding platform 12, and the slide rail 2 carrying the water squeezing or acid rollers 901, 902 is fixed on on bracket 1.

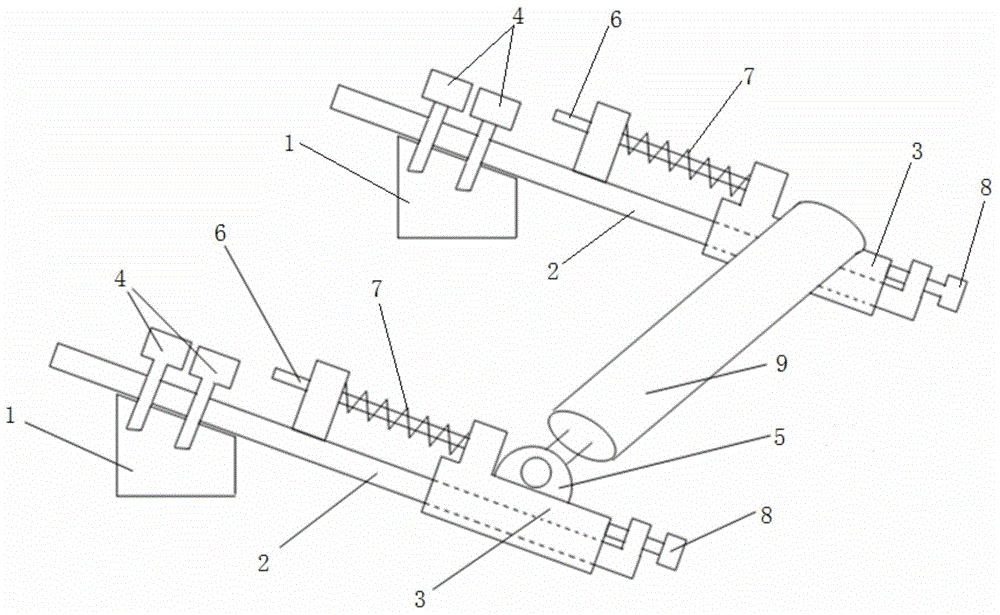

[0030] Such as image 3 , 4 As shown, the water squeezing or acid roll device for raw foil machine of the present invention includes a water squeezing or acid roll 9 or 901 or 902, two brackets 1, two slide rails 2, two linear sliders 3, two belts There is an adjustment screw 6 with a spring 7 and two revers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com