A Thermal Spraying Method for Slab Continuous Casting Chamfer Mold Narrow Surface Copper Plate

A technology of chamfering crystallizers and narrow-faced copper plates, which is applied in coating, molten spraying, metal material coating processes, etc., can solve the problem that the transverse cracks at the corners of right-angle continuous casting cannot be effectively controlled and reduce the service life of mold copper plates , Rolled steel plate edge strips or folds and other problems, to achieve the effect of easy control of the production process, convenient adjustment of the nozzle angle, and short production period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

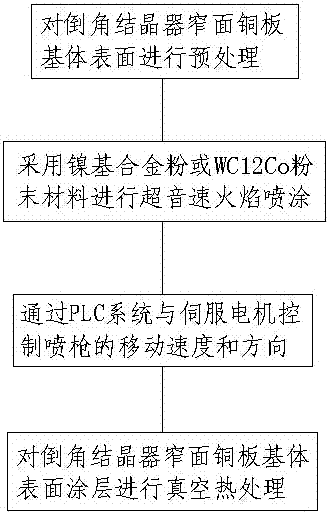

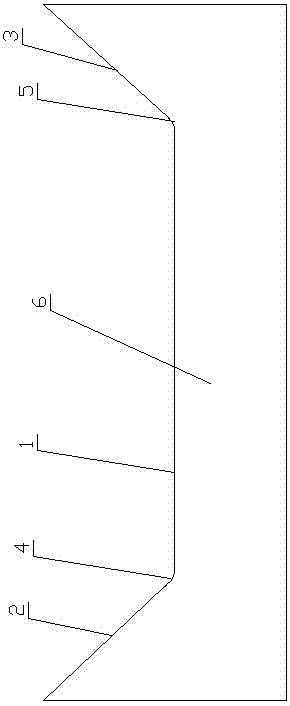

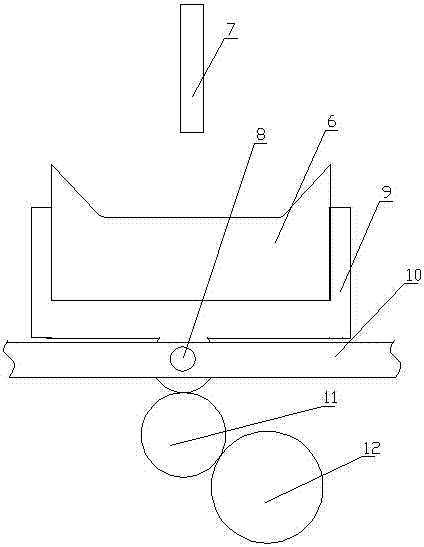

[0045] Such as figure 1 and figure 2 Shown: the invention provides a kind of thermal spraying method of slab continuous casting chamfering crystallizer narrow face copper plate, comprises the steps:

[0046] 1) Pretreatment of the surface of the chamfering crystallizer narrow surface copper plate substrate, firstly perform ultrasonic cleaning, and then prepare the transition layer by electroplating;

[0047] 2) Use supersonic flame spraying equipment to spray the substrate surface of the chamfering crystallizer narrow surface copper plate, and the spraying material is WC12Co powder material;

[0048] 3) Use the PLC control system to control the moving speed of the spray gun, and use the servo motor to synchronously adjust the angle rotation of the support for installing the narrow copper plate of the chamfering crystallizer to ensure that the spray gun is in contact with the narrow copper plate of the chamfering crystallizer during the spraying process. The working surface ...

Embodiment 2

[0054] Such as figure 1 and figure 2 Shown: the invention provides a kind of thermal spraying method of slab continuous casting chamfering crystallizer narrow face copper plate, comprises the steps:

[0055] 1) Pretreatment of the surface of the chamfering crystallizer narrow surface copper plate substrate, firstly perform ultrasonic cleaning, and then prepare the transition layer by electroplating;

[0056] 2) Use supersonic flame spraying equipment to spray the surface of the copper plate substrate on the narrow side of the chamfering crystallizer, and the spraying material is nickel-based alloy powder material;

[0057] 3) Use the PLC control system to control the moving speed of the spray gun, and use the servo motor to synchronously adjust the angle rotation of the support for installing the narrow copper plate of the chamfering crystallizer to ensure that the spray gun is in contact with the narrow copper plate of the chamfering crystallizer during the spraying process...

Embodiment 3

[0063] Such as figure 1 and figure 2 Shown: the invention provides a kind of thermal spraying method of slab continuous casting chamfering crystallizer narrow face copper plate, comprises the steps:

[0064] 1) Pretreatment of the surface of the chamfering crystallizer narrow surface copper plate substrate, firstly perform ultrasonic cleaning, and then prepare the transition layer by electroplating;

[0065] 2) Use supersonic flame spraying equipment to spray the substrate surface of the chamfering crystallizer narrow surface copper plate, and the spraying material is WC12Co powder material;

[0066] 3) Use the PLC control system to control the moving speed of the spray gun, and use the servo motor to synchronously adjust the angle rotation of the support for installing the narrow copper plate of the chamfering crystallizer to ensure that the spray gun is in contact with the narrow copper plate of the chamfering crystallizer during the spraying process. The working surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com