800MPa grade high-ductility low-density steel and manufacturing method thereof

A manufacturing method and low-density technology, applied in the field of low-density steel and its manufacturing, can solve the problems of poor cold bending performance of steel plate, high manufacturing cost, center and edge cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described in conjunction with the embodiments and the accompanying drawings.

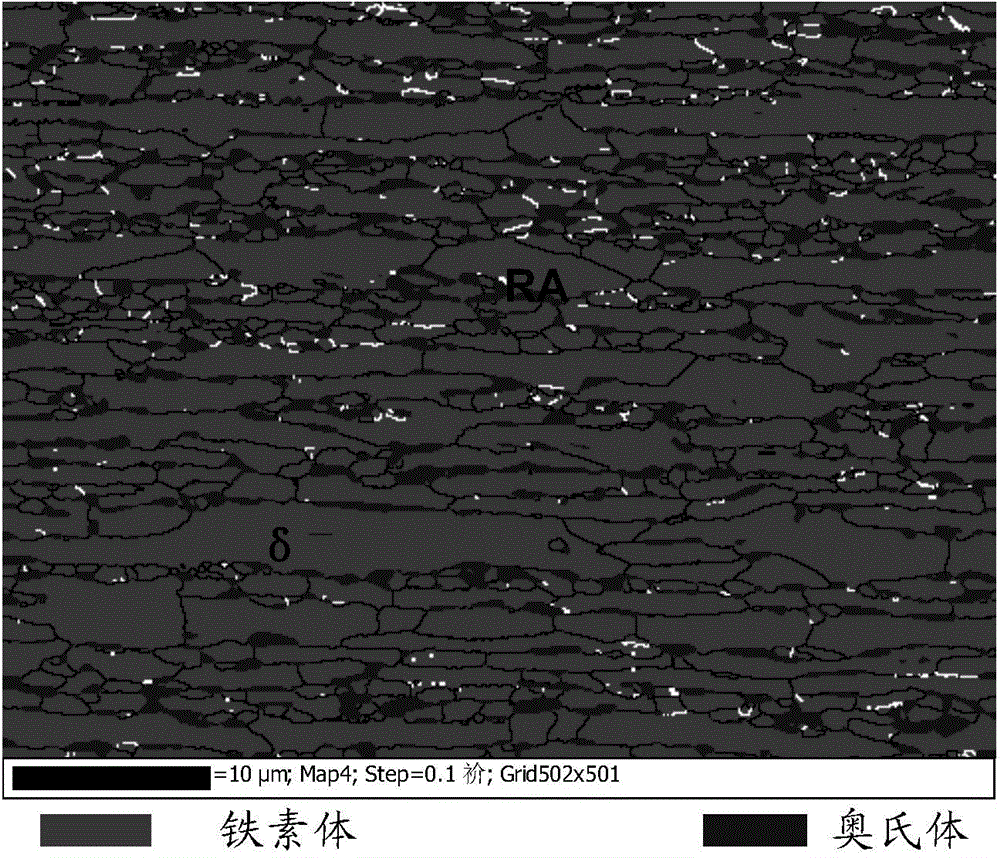

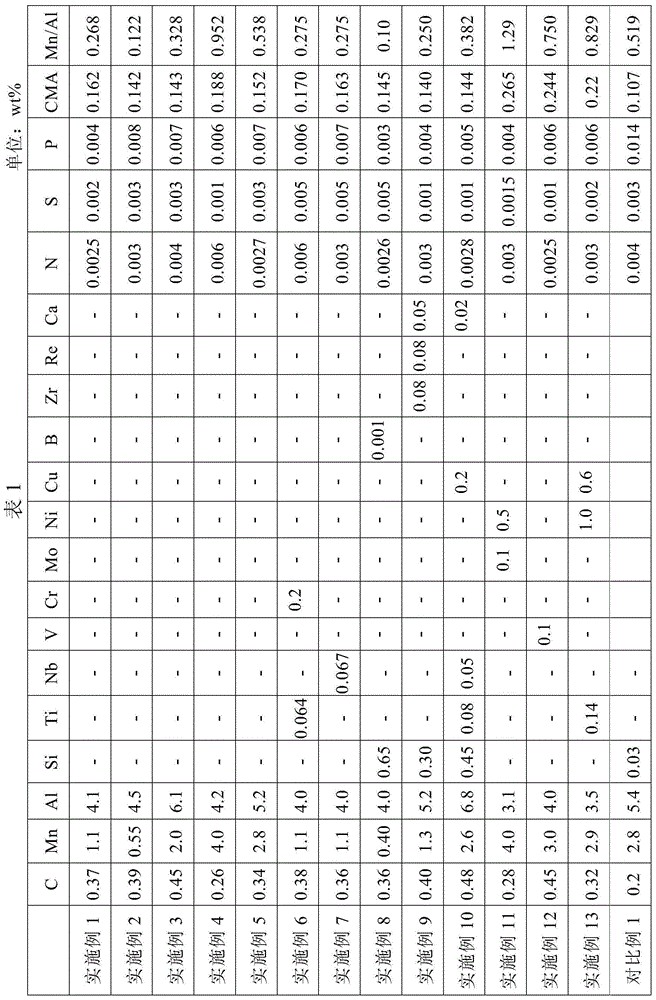

[0075] Table 1 is the composition of the steel grades of the embodiments of the present invention and comparative examples, Table 2 is the manufacturing process of the steel grades of the embodiments of the present invention and comparative examples, and Table 3 is the retained austenite in the microstructure of the steel plates of the embodiments of the present invention and comparative examples The volume fraction, C content and mechanical properties of the steel plate.

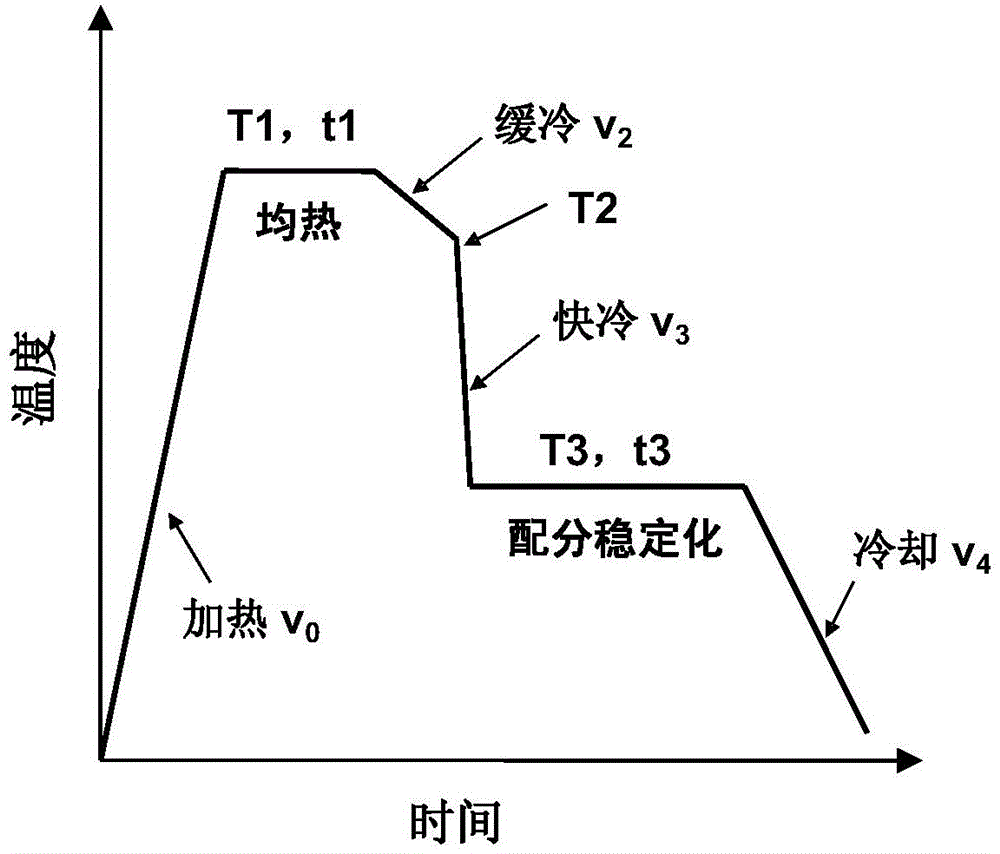

[0076] The steel materials with the composition shown in Table 1 are smelted and cast to make billets. After the slab is heated at a reheating temperature (RHT) of 1200°C, the slab is hot-rolled, and the hot-rolling finish rolling is completed at a finishing temperature (FT) above 880°C. The thickness of the hot-rolled steel plate is about 3.2 mm. The hot-rolled steel plate is rapidly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com