Apparatus for producing combustible gas by catalytically pyrolyzing refuse and method thereof

A catalytic cracking and gas technology, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, condensed non-gaseous material gas purification, etc., can solve the problems of inability to directly use the production industry, combustible gas treatment, and unrealized automatic production level, etc. , to achieve the effect of improving the automation level of split coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

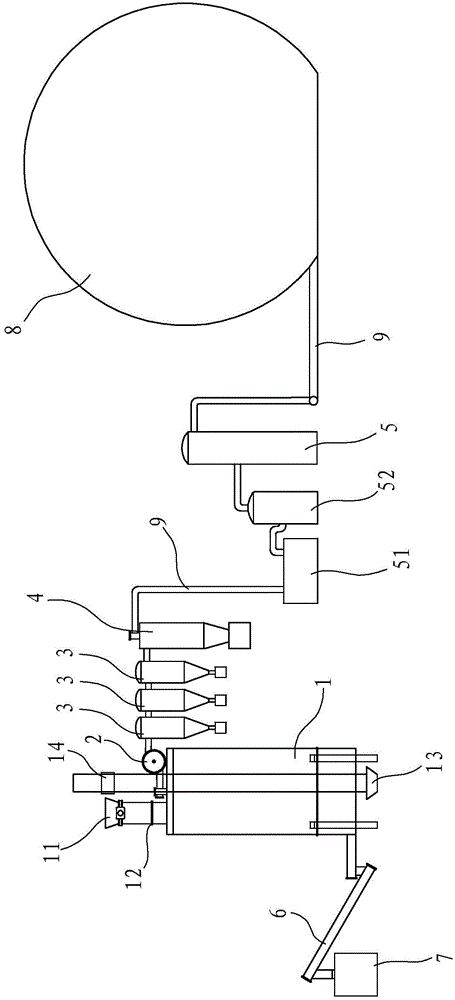

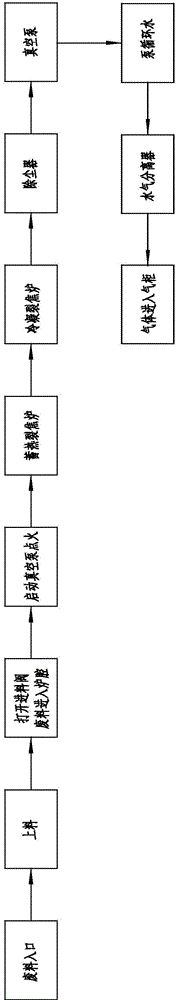

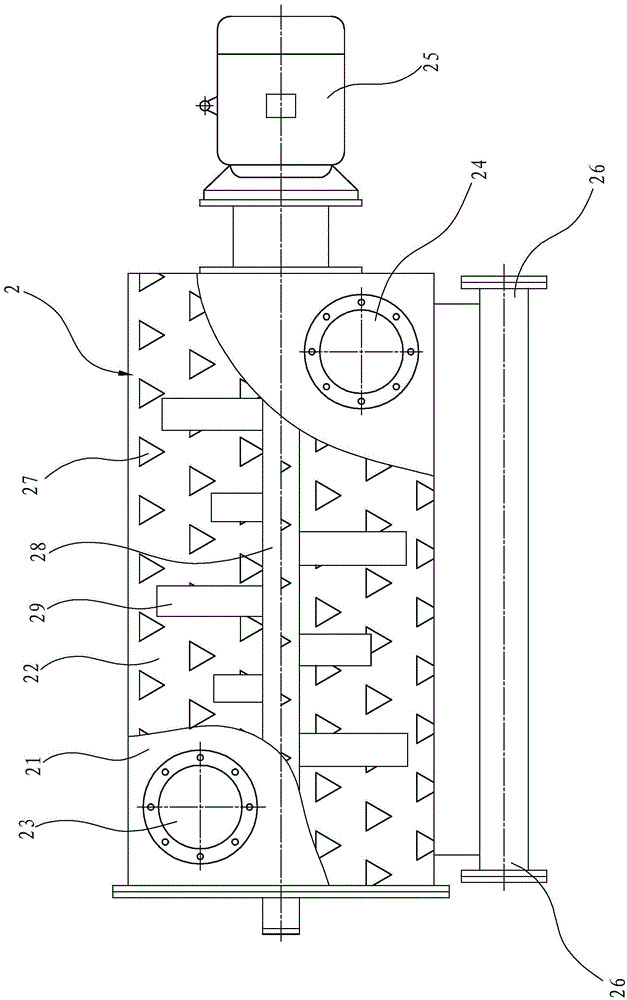

[0033] Such as Figures 1 to 8 As shown, the present invention discloses a device for producing combustible gas by catalytic cracking of waste materials, including a cracking furnace 1, a heat storage decoker 2, a condensation decoker 3, a dust collector 4, an ash discharge auger 6, and an ash storage box 7. Moisture separator 5 and gas cabinet 8, etc.

[0034] Wherein, the gas outlet of cracking furnace 1 links to each other with the air inlet of heat storage decoker 2, and the gas outlet of described heat storage decoker 2 links to each other with the air inlet of condensation decoker 3, and said condensation decoker The air outlet of 3 is connected with the air inlet of dust remover 4, the air outlet of said dust remover 4 is connected with the air inlet of water-gas separator 5, the air outlet of said water-gas separator 5 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com