A kind of preparation method of zwitterionic copolymer for drilling fluid

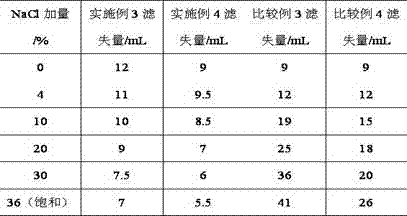

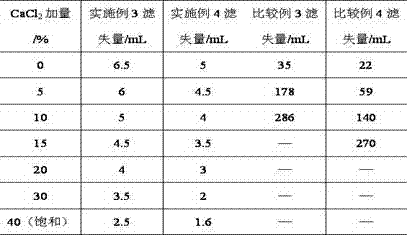

A zwitterionic and copolymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem that the polymer has limited salt resistance and calcium resistance, cannot achieve the "reverse polyelectrolyte" effect, and the quantity is not equal, etc. problems, to achieve the effect of increasing the hydrodynamic volume, easy cleaning and maintenance, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

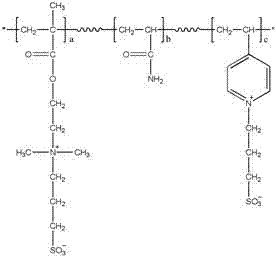

Method used

Image

Examples

Embodiment 1

[0032] First prepare methacryloyloxyethyl-N,N-dimethylpropanesulfonate (DMAPS)

[0033] Weigh 630g of dimethylaminoethyl methacrylate (DM) into the reactor, then put it into a constant temperature water bath, heat and start stirring. Then 122g of 1,3-propane sultone (PS) was weighed and directly added to DM at a reaction temperature of 35°C. After stirring for 1.5h, the crude product of DMAPS was obtained. Transfer the crude DMAPS product to a large piece of filter paper, wrap it in a Soxhlet extractor, and use ethanol as a solvent to extract it for 1 hour. After the extraction, put the filter paper bag in a drying oven and dry it at 40°C to obtain The pure DMAPS monomer has a yield of 92.8%, (the yield is the ratio of the mass of the product actually obtained and the mass of the theoretical product obtained by the stoichiometric reaction).

Embodiment 2

[0039] Preparation of 4-vinylpyridinepropanesulfonic acid ylide (VPPS)

[0040] (1) Weigh 105g of 4-vinylpyridine (4-VP), 125g of 1,3-propane sultone (PS), 500g of organic solvent benzene, and 0.75g of diethylhydroxylamine;

[0041] (2) Divide the organic solvent benzene into three parts equally, dissolve and mix with 4-vinylpyridine, 1,3-propane sultone and auxiliary agent diethylhydroxylamine respectively;

[0042] (3) Add the obtained three mixed solutions into the reactor one by one, react at 70°C for 2h, then filter under reduced pressure, wash with benzene for 2-3 times, and dry at 50°C for 15h to obtain 4-ethylene Base pyridine propanesulfonic acid ylide, finally obtain 2136g of light yellow solid powder product through calculation.

Embodiment 3

[0044] Weigh 50gDMAPS, 60gAM and 40gVPPS respectively, add a certain amount of deionized water to dissolve and transfer to the reactor, the total monomer concentration is 35%. Access to N 2 Deoxygenation was performed for 1 hour, and the temperature was raised to 60° C., kept for 30 minutes, and then 0.9 g of potassium persulfate was added. After 6 hours of reaction, a gel-like solid was obtained, which was precipitated with acetone to obtain a white precipitate. After drying at 110°C for 24 hours, it was pulverized to finally obtain DMAPS / AM / VPPS zwitterionic copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com