Fused zirconia corundum low-seepage brick production method

A production method and technology of zirconium corundum, which is applied in the field of refractory materials to achieve the effects of low cost, reduced erosion damage, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

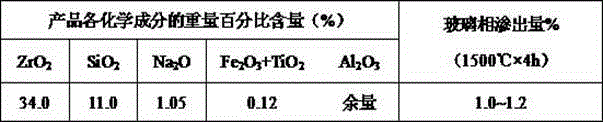

Image

Examples

Embodiment 1

[0016] The production method of the fused zirconium corundum low exudation brick comprises the following steps:

[0017] (1) Preparation of raw materials, the raw materials are made by mixing 20% of clinker and 80% of raw meal by weight percentage;

[0018] Wherein, the clinker is calculated by weight percentage: sodium oxide (Na 2 O) 1.3%, zirconia (ZrO 2 ) 32.7%, silicon dioxide (SiO 2 ) 14% and aluminum oxide (Al 2 O 3 ) 52% mixed uniformly; the particle size of clinker is less than or equal to 20mm;

[0019] The raw meal is prepared by mixing 15% of zircon sand, 77% of calcined alumina powder, 7% of desiliconized zirconium and 1% of soda ash by weight percentage;

[0020] (2) Electric furnace melting, pour the evenly mixed raw materials into the electric furnace and melt into a material liquid, the melting temperature is 1900-1930 ℃, the melting time is 65 minutes, and the oxygen is blown twice during the melting process, and the first time is 55 minutes after melti...

Embodiment 2

[0024] The production method of the fused zirconium corundum low exudation brick comprises the following steps:

[0025] (1) Preparation of raw materials, the raw materials are made by mixing 22.5% of clinker and 77.5% of raw meal by weight percentage;

[0026] Wherein, the clinker is calculated by weight percentage: sodium oxide (Na 2 O) 1.4%, zirconia (ZrO 2 ) 32%, silicon dioxide (SiO 2 ) 14% and aluminum oxide (Al 2 O 3 ) 52.5% mixed uniformly; the particle size of clinker is less than or equal to 20mm;

[0027] The raw meal is prepared by mixing 16% of zircon sand, 68.5% of calcined alumina powder, 14% of desiliconized zirconium and 1.5% of soda ash by weight percentage;

[0028] (2) Electric furnace melting, pour the evenly mixed raw materials into the electric furnace and melt into the material liquid, the melting temperature is 1900-1930 ℃, the melting time is 66 minutes, and the oxygen is blown twice during the melting process, and the first time is 55 minutes af...

Embodiment 3

[0032] The production method of the fused zirconium corundum low exudation brick comprises the following steps:

[0033] (1) Preparation of raw materials, the raw materials are made by mixing 25% of clinker and 75% of raw meal by weight percentage;

[0034] Wherein, the clinker is calculated by weight percentage: sodium oxide (Na 2 O) 1.45%, zirconia (ZrO 2 ) 32.4%, silicon dioxide (SiO 2 ) 15% and aluminum oxide (Al 2 O 3 ) 51.15% mixed uniformly; the particle size of clinker is ≤20mm; the raw meal is calculated by weight percentage: zircon sand 22.5%, calcined alumina powder 63.5%, desiliconized zirconium 12.5% and soda ash 1.5% made by mixing evenly;

[0035] (2) Electric furnace melting, pour the evenly mixed raw materials into the electric furnace and melt into a material liquid, the melting temperature is 1900-1930 ℃, the melting time is 67 minutes, and the oxygen is blown twice during the melting process, and the first time is 55 minutes after melting. , blow ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com