A kind of method adopting perlite fine powder to prepare puffed product

A technology for puffed products and perlite, which is applied in the field of preparing puffed products by using fine perlite powder, can solve the problems of high energy consumption, neglect of chemical modification effect of fine perlite powder, low profit margin, etc., and achieves low energy consumption and improved utilization. The effect of high value and profit margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

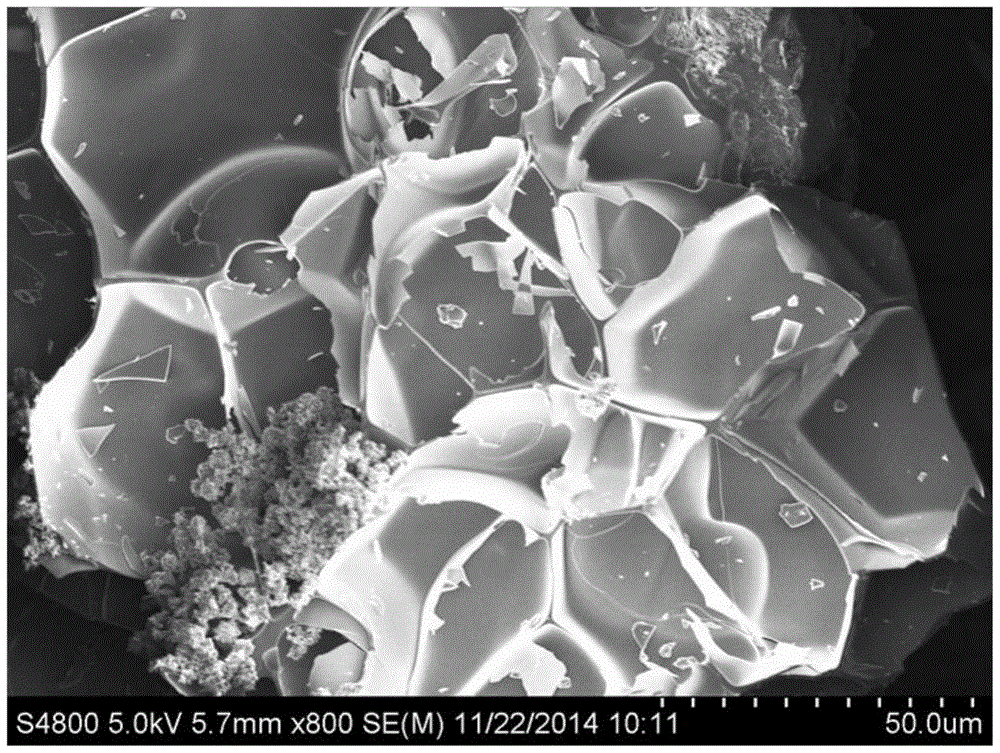

[0041] In this example, the chemical composition and content of the fine perlite tailings powder used are shown in Table 1-1; the selected expanded perlite fine powder is produced during the expansion of perlite from the same origin, so the two The chemical composition is basically similar, except that H 2 The O content is slightly different. Soda water glass used, modulus m=3.29, silicon dioxide (SiO 2 ) content is 26.5%, sodium oxide (Na 2 O) content was 8.3%. The raw materials required in this example were not subjected to any optimization processing before the test.

[0042] Table 1-1 Chemical composition and content of perlite tailings fine powder

[0043] chemical composition SiO 2

Al 2 o 3

FeO CaO MgO K 2 o

Na 2 o

h 2 o

Content (wt%) 69.75 12.20 0.5 0.6 0.14 2.13 3.05 5.5

[0044] By adjusting the addition ratio of perlite fine powder, lightweight aggregates with different foaming temperatures can be ...

Embodiment 2

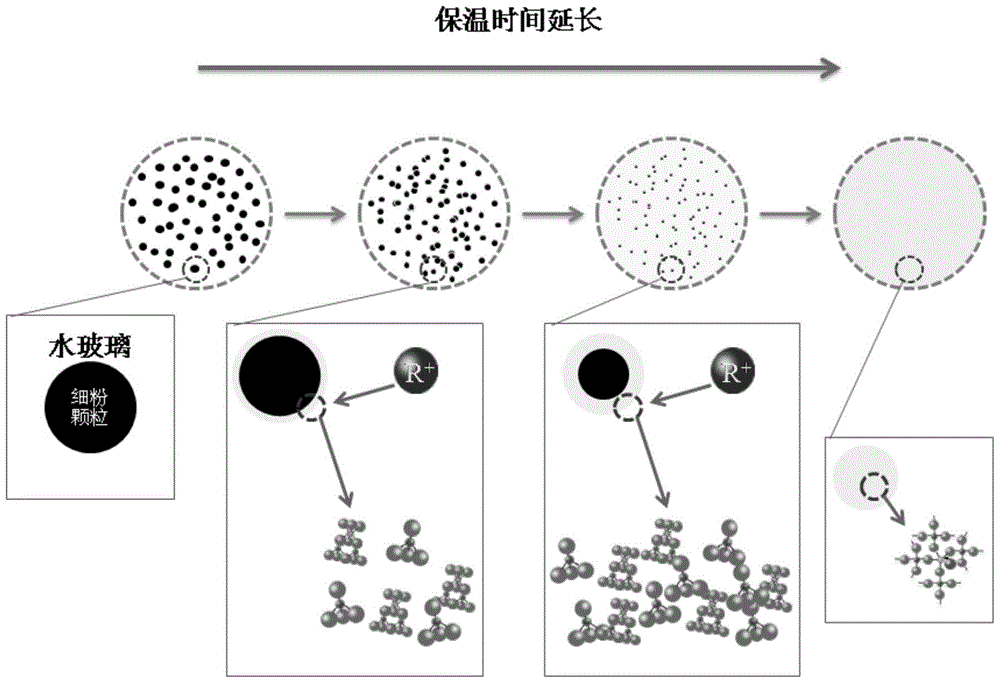

[0059] In this example, the influence of the holding time on the expansion performance and chemical stability of the puffed product is mainly studied. The weight loss rate is the main indicator of the chemical stability of lightweight aggregates. The test method for the weight loss rate of puffed products is as follows:

[0060] 1. Take an appropriate amount of puffed products and place them in the mill, and grind them for 40 times;

[0061] 2. Weigh about 3g of crushed fine powder (accurate to 4 decimal places), and pour it into a beaker filled with hot water to ensure that there are no suspended particles;

[0062] 3. Place the beaker on a heater at 100°C for 2 hours, then filter (weigh the filter paper in advance), and dry it in an oven at 100°C together with the filter paper until constant weight. The expression of weight loss rate is as follows:

[0063]

[0064] In the formula: w is the weight loss rate of the material, expressed as a percentage; G 0 is the origina...

Embodiment 3

[0085] In this example, the influence of the water glass modulus on the performance of the puffed product of the present invention is mainly explored. Choose A and B two kinds of sodium silicate with different modulus, and the parameters of the silicate are shown in Table 3-1:

[0086] Table 3-1 Two kinds of sodium silicate parameters used in this embodiment

[0087]

[0088] Expanded perlite fine powder and perlite tailings fine powder are used as additives respectively, and the solid-liquid ratio is set to 1:3, 1:4, 1:5, 1:6. The test results of puffing performance and physical and chemical properties of puffed products are shown in Table 3-2 to 3-4:

[0089] Table 3-2 Performance test results of puffed products made of water glass A and expanded perlite fine powder

[0090]

[0091] Table 3-3 Performance test results of puffed products made of B water glass and expanded perlite fine powder

[0092]

[0093] Table 3-4 Performance test results of puffed products m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com