Resourceful treatment process for alkali-minimization waste water

A technology of alkali reduction wastewater and treatment process, applied in the field of water treatment, can solve problems such as poor biodegradability, impact, and deterioration of effluent water quality, and achieve the effect of saving treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The water quality of the alkali reduction waste water to be treated is as follows:

[0029] serial number

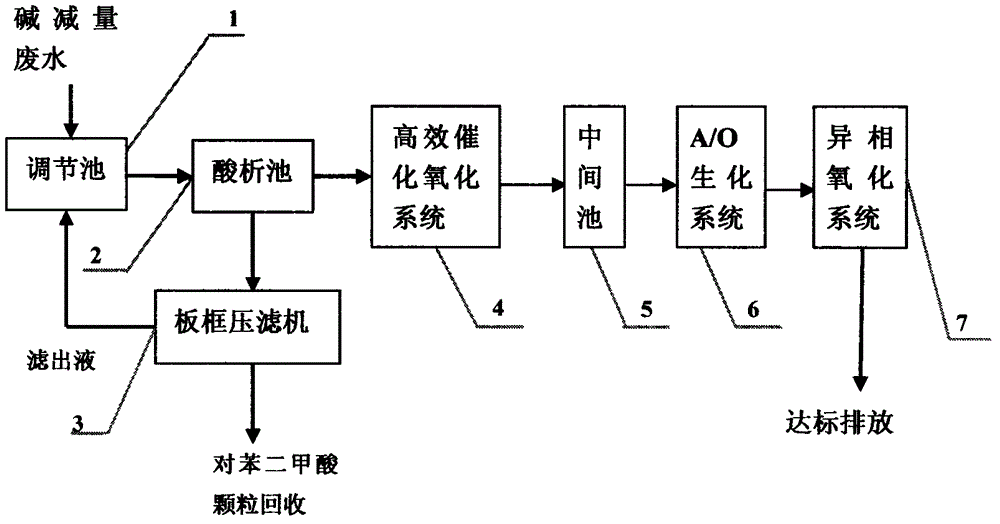

[0030] Wastewater is treated through the following steps: (such as figure 1 shown)

[0031] (1) Alkali decrement wastewater is discharged into the adjustment pool 1 separately, and the residence time in the adjustment pool 1 is 20 hours; after adding 98% of the concentrated sulfuric acid, the waste water is discharged into the acid analysis pool 2, so that it enters the acid analysis pool 2 The pH of the waste water is controlled below X, and the residence time of the waste water in the acid analysis tank is 5-8 hours;

[0032] (2) The supernatant in the acid analysis tank 2 is discharged into the follow-up high-efficiency catalytic oxidation system 4; the terephthalic acid precipitate at the bottom of the acid analysis tank is transported by a pump into the plate and frame filter press 3 for pressure filtration, and terephthalic acid is recovered Part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com