Carbon nanotube microsphere and preparation method and application thereof

A carbon nanotube microsphere and carbon nanotube technology, applied in the field of material science, can solve problems such as difficulty in obtaining carbon nanotube microspheres, and achieve the effects of simple preparation method, strong controllability and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Another aspect of the present invention provides a method for preparing carbon nanotube microspheres, comprising: at least uniformly dispersing carbon nanotubes in a solvent to form a surfactant-free dispersion and spray drying to obtain the carbon nanotube microspheres. nanotube microspheres.

[0036] The form of the carbon nanotube microsphere material in the present invention can be powder or granular.

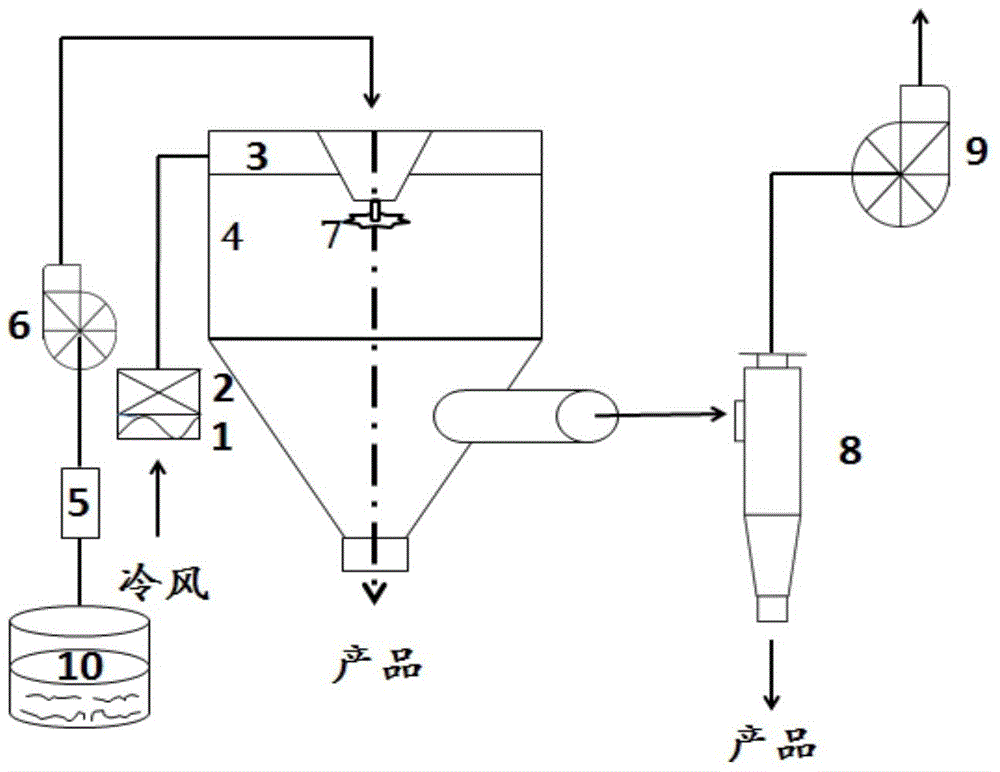

[0037] More specifically, as one of the feasible implementations of the present invention, please refer to figure 1 , the preparation method may include: at least dispersing the carbon nanotubes in a solvent to obtain a surfactant-free dispersion, and then input the dispersion into an atomizer of a spray dryer to form tiny mist droplets, and making the mist droplets in the spray dryer co-currently contact with the hot air flow, so that the solvent in the liquid mist droplets evaporates rapidly, and then the carbon nanotubes in the liquid mist droplets are aggregated...

Embodiment 1

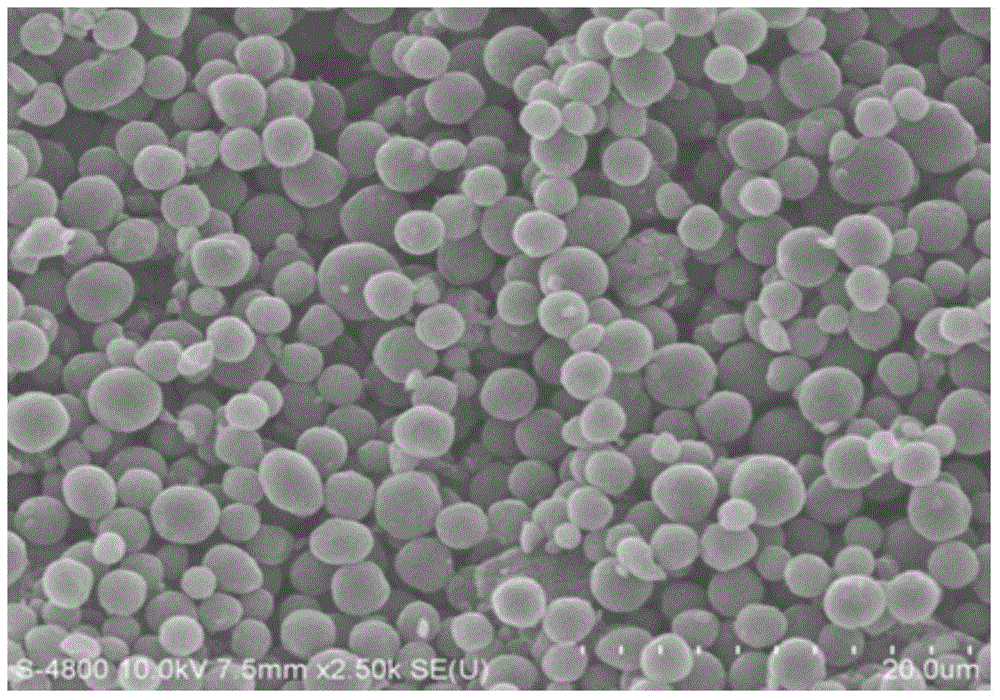

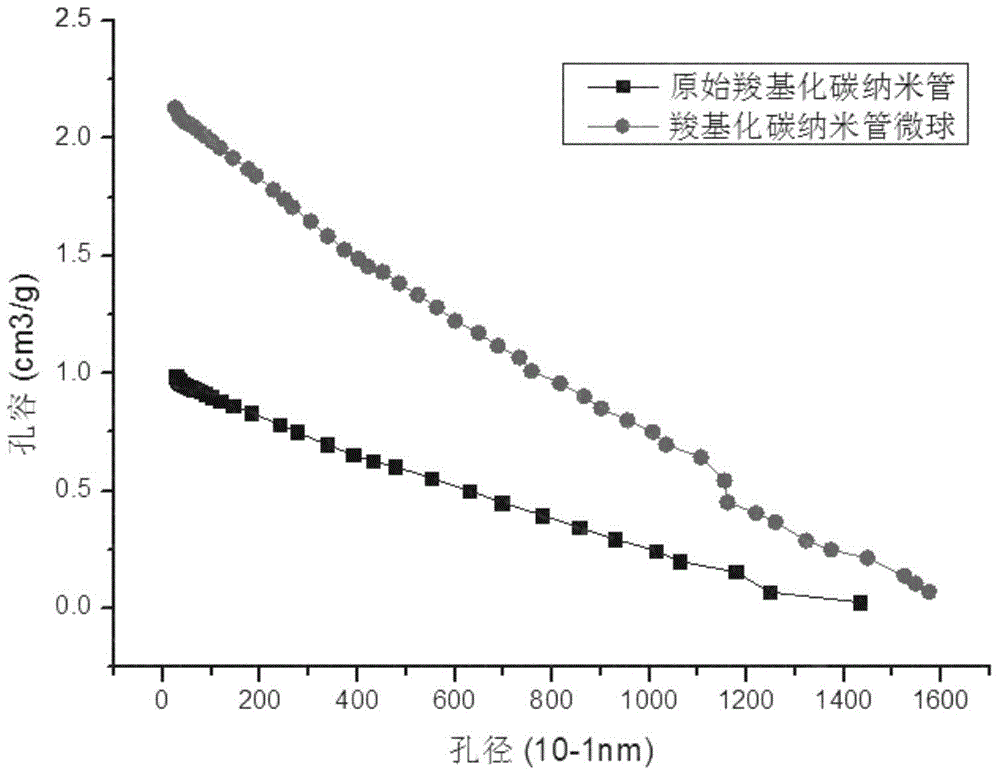

[0053] Example 1: First, add 4 g of multi-walled carbon nanotubes with a carboxyl group content of 3.86 wt% to 200 ml of deionized water, and then add 20 mL of 37% concentrated ammonia water. Sealed and stirred, 130W ultrasonic probe ultrasonic treatment for 10h, so that the sample is evenly dispersed. When finished, add the sample to the spray dryer. The air inlet temperature was set at 200°C, the air outlet temperature was set at 150°C, the spray pressure was set at 40MPa, and the injection volume was set at 500mL / h. After drying, the carboxylated carbon nanotube microsphere material was obtained, and then the The obtained samples were tested for specific surface area and pore size distribution. refer to Figure 2a It is the SEM picture of the carbon nanotube microsphere material, Figure 2b It is a comparison chart of the porosity of the carbon nanotube microspheres and the non-spheroidized carbon nanotubes. Afterwards, particle size analysis is carried out to the obt...

Embodiment 2

[0054] Example 2: First, add 4 g of multi-walled carbon nanotubes without any chemical treatment to 200 ml of deionized water, and then add 20 ml of absolute ethanol. Sealed and stirred, 130W ultrasonic probe ultrasonic treatment for 10h, so that the sample is evenly dispersed. When finished, add the sample to the spray dryer. The air inlet temperature was set at 200°C, the air outlet temperature was set at 150°C, the spray pressure was set at 40MPa, and the sample injection volume was set at 500mL / h. After drying, the carbon nanotube microsphere material was obtained, and the obtained sample Perform specific surface area and pore size distribution tests. Figure 4a SEM photographs of untreated pure multi-walled carbon nanotube microspheres, Figure 4b It is a comparison chart of the porosity of untreated pure MWCNT microspheres and untreated pure MWCNT microspheres. Afterwards, particle size analysis was performed on the obtained microspheres, the results of which can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com