Horizontal type C-type steel transverse moving and turnover device

A technology of turning device and C-shaped steel, which is applied in the direction of transportation and packaging, conveyor objects, object stacking, etc., can solve the problems of waste of manpower, low degree of automation, and low efficiency, and achieve the goal of improving production efficiency and reducing production accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

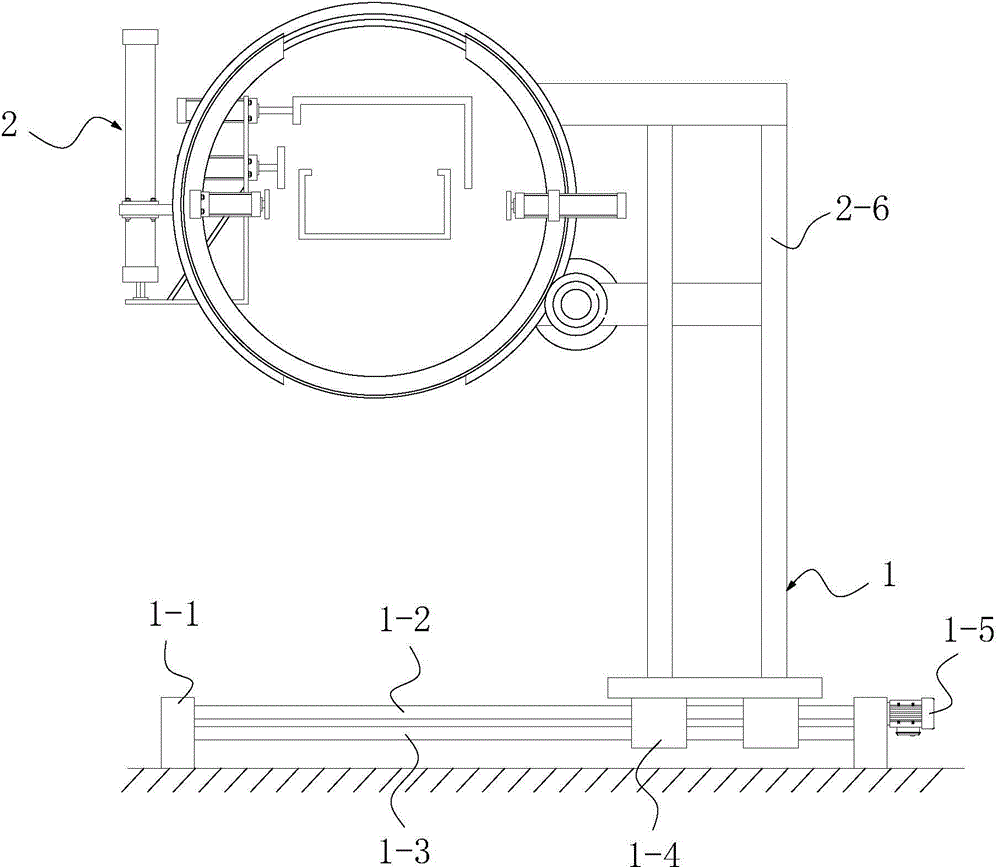

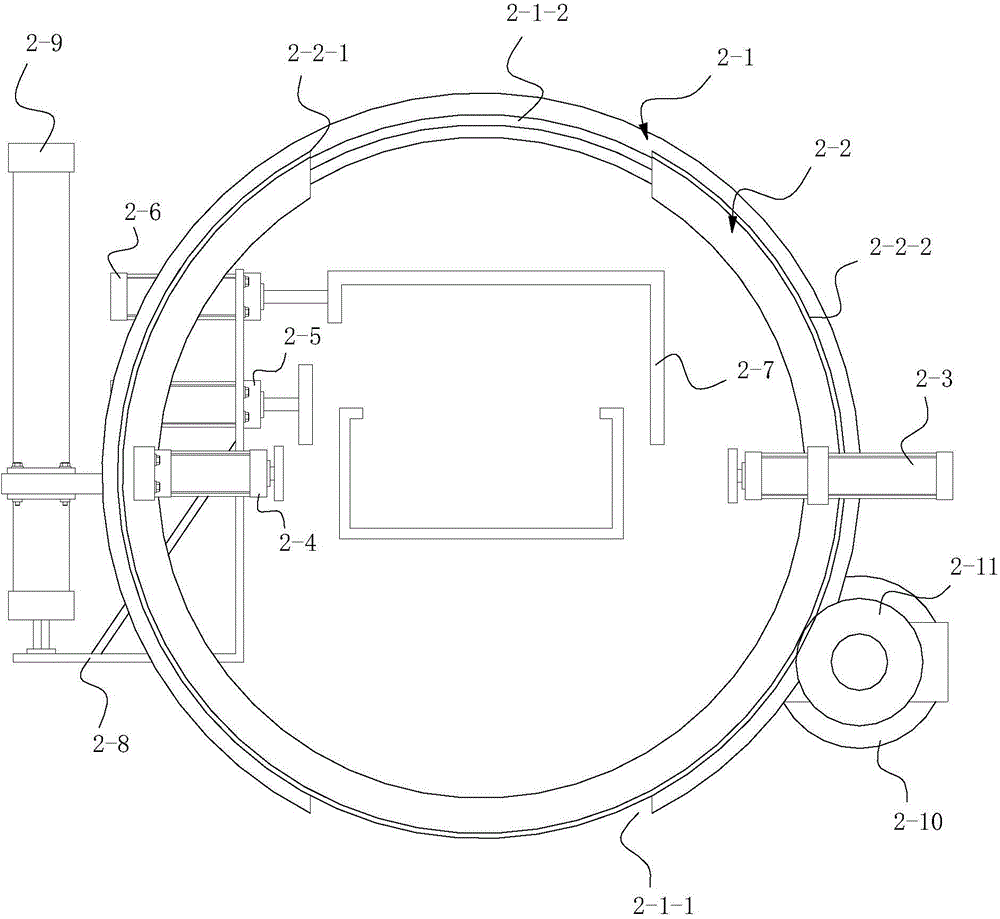

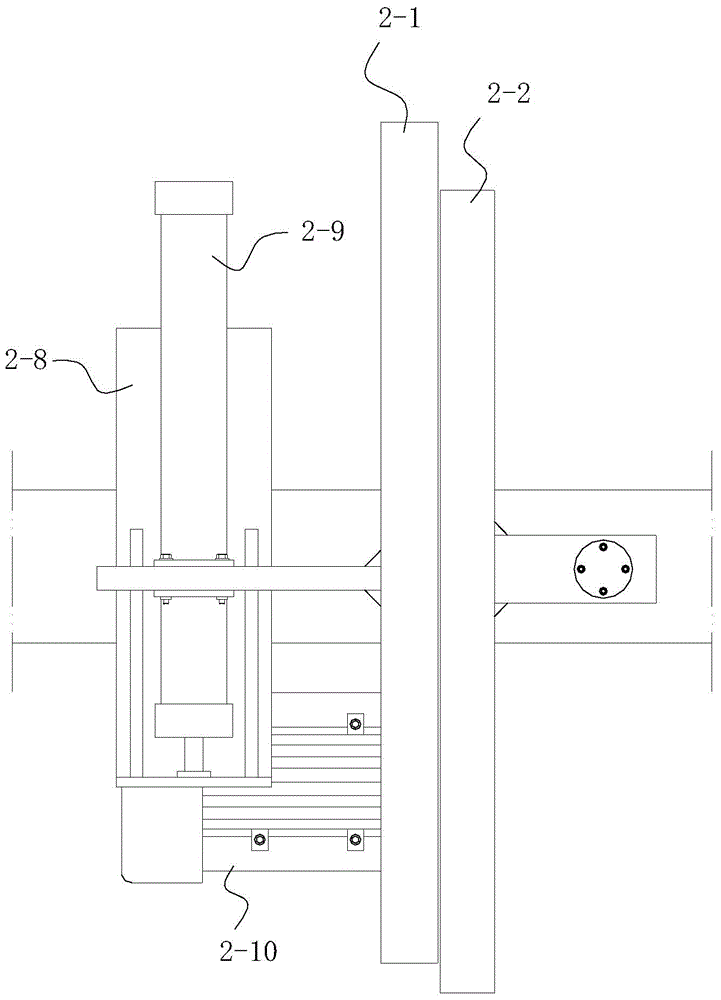

[0022] See figure 1 , A horizontal C-shaped steel traversing and turning device, including a traversing mechanism 2 and a turning clamping mechanism 3. The traverse mechanism 2 is used for moving the C-shaped steel, and the turning clamping mechanism 3 is used for clamping and turning the C-shaped steel.

[0023] The lateral movement mechanism 2 includes a base frame 1-1, a horizontal lead screw 1-2, a horizontal guide rod 1-3, a lateral movement block 1-4, a servo motor 1-5, and a vertical frame 1-6. In this embodiment, the underframe 1-1 is directly fixed on the ground. Both ends of the horizontal screw 1-2 are mounted on the bottom frame 1-1 through bearings. Both ends of the horizontal guide rod 1-3 are fixed on the bottom frame 1-1. The traverse movable block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com