Oil-water-air three-phase minimum quantity lubrication cooling system

A technology of minimal quantity lubrication and cooling system, applied in the field of lubrication system, which can solve the problems of unstable water pressure, falling off of oil supply pipe and water supply pipe, and interruption of flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

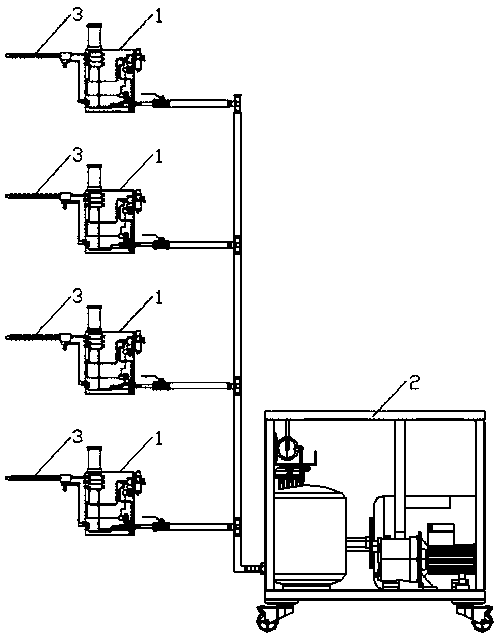

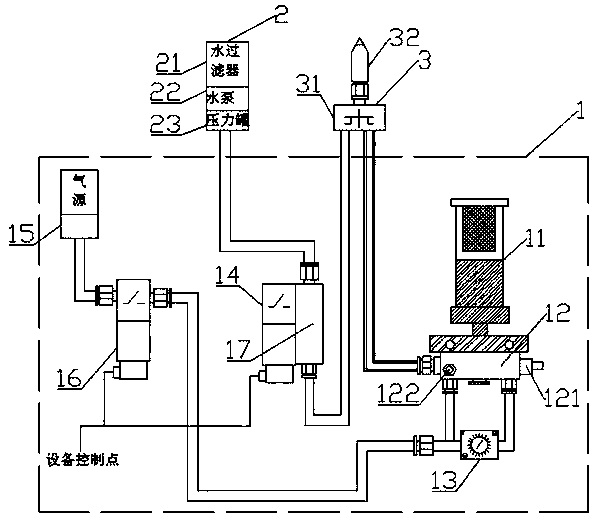

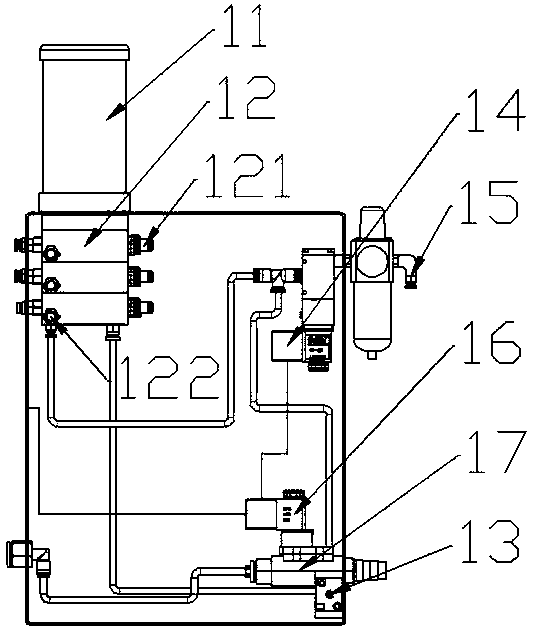

[0047] figure 1 It is a schematic structural diagram of an oil-water-air three-phase minimum quantity lubrication cooling system.

[0048] Such as figure 1 As shown, the oil-water-air three-phase micro-lubrication cooling system in this embodiment is illustrated by taking the structure of a constant-pressure centralized water supply device and four micro-quantity oil-gas injection devices as an example. In practical applications, the number of micro-injection devices can be set according to needs.

[0049] The oil-water-air three-phase micro-lubrication cooling system includes: four micro-injection oil-air devices 1, a constant-pressure centralized water supply device 2, and oil-water-air injection device 3. The oil-water-air spraying device 3 is connected to the micro-spraying oil-gas device 1 through a hose; the constant-pressure centraliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com