Threaded steel straightening device and straightening method

A technology of straightening device and rebar, applied in the field of straightening device, can solve the problem of inability to straighten rebar, and achieve the effect of avoiding rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

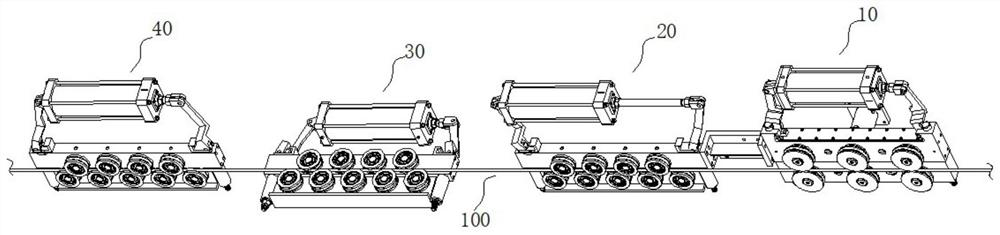

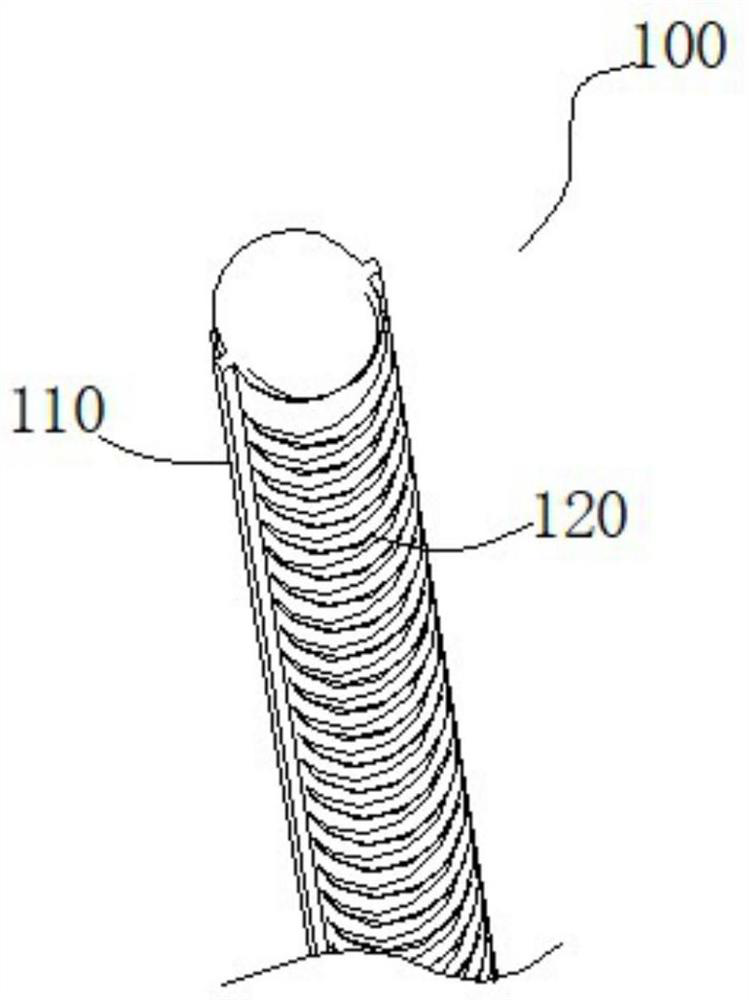

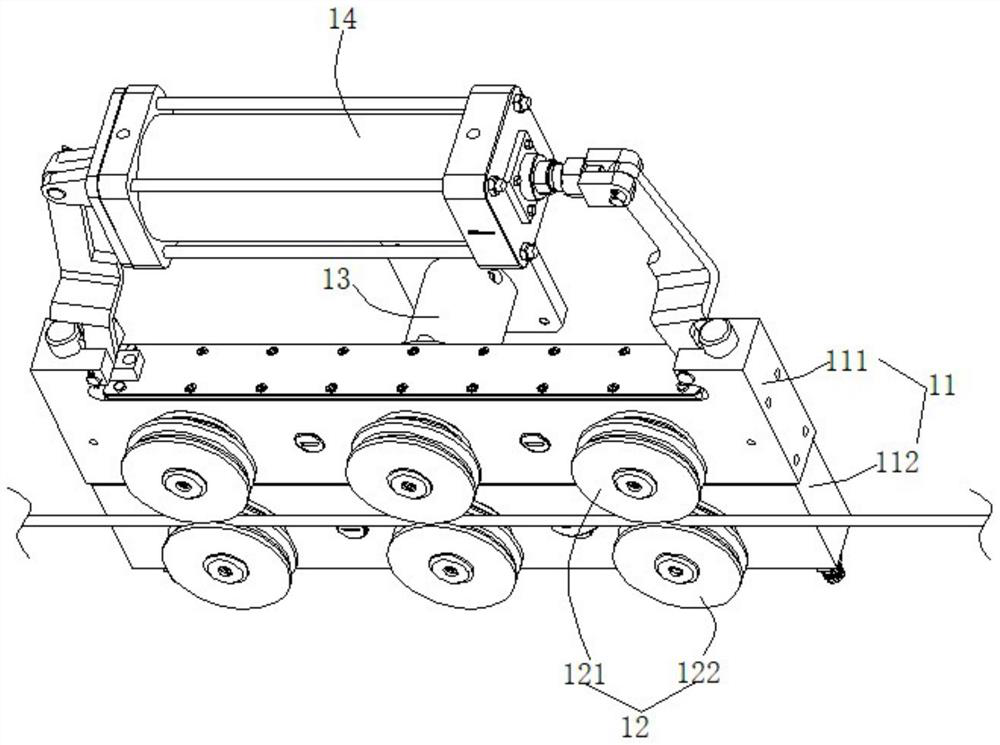

[0057] refer to Figure 1-8 , a straightening device for threaded steel, comprising a feeding mechanism 10, a first straightening mechanism 20, a second straightening mechanism 30 and a third straightening mechanism 40 arranged in sequence along the conveying direction of the feeding mechanism 10;

[0058] The feeding mechanism 10 is suitable for clamping the rebar in the vertical direction and for conveying the rebar in the horizontal direction;

[0059] The first straightening mechanism 20 is suitable for clamping the rebar in the vertical direction for straightening the straightness of the rebar on the vertical plane;

[0060] The second straightening mechanism 30 is suitable for clamping the rebar in the horizontal direction, and is used to straighten the straightness of the rebar on the horizontal plane; wherein, the second straightening mechanism also has a limiting structure, and the limiting structure is used to limit the rebar rotate along its axis;

[0061] The thi...

Embodiment 2

[0093] On the basis of Embodiment 1, this embodiment provides a method for straightening rebar, including:

[0094] Equipment preparation step: provide the straightening device as described in embodiment one;

[0095] Pre-feeding step: first control the first straightening channel of the first straightening mechanism, the second straightening channel of the second straightening mechanism and the third straightening channel of the third straightening mechanism are all in the loose state, start feeding Mechanism, the feeding mechanism transports the rebar to the first straightening passage of the first straightening mechanism, the second straightening passage of the second straightening mechanism and the third straightening passage of the third straightening mechanism in sequence, and stops feeding Material organization;

[0096] Compression step: then control the first straightening passage of the first straightening mechanism and the third straightening passage of the third s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com