Acrylic acid catalyst and synthesis method of acrylic acid

A catalyst, acrylic technology, used in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor stability and low selectivity, and achieve molding handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

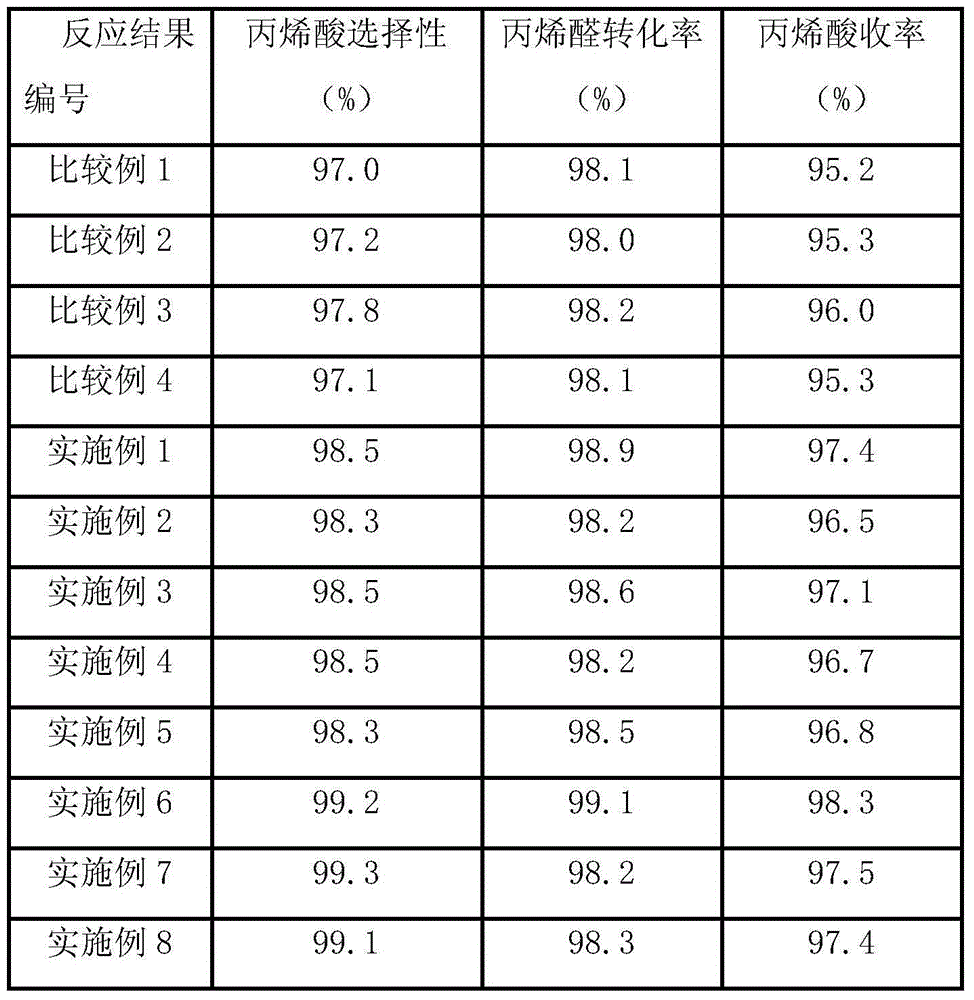

Examples

Embodiment 1

[0084] 1. Catalyst preparation

[0085] a) 500 grams of ammonium heptamolybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O and 13.3 grams of KOH were added to 500 grams of warm water at 70°C, and stirred to make them all dissolve to form material I;

[0086] b) Add 123.5 grams of ammonium metavanadate NH to 250 grams of water 4 VO 3 forming material II;

[0087] c) 52.1 grams of antimony trioxide Sb 2 o 3 Add 100 grams of 70 ℃ hot water, stir and dissolve, then add 171 grams of copper nitrate Cu(NO 3 ) 2 ·3H 2 O, 82 grams of lanthanum nitrate La (NO 3 ) 2 .6H 2 O, 82 grams of cerium nitrate Ce (NO 3 ) 2 .6H 2 O and 95.3 grams of ammonium tungstate stirring and dissolving make material III;

[0088] d) adding materials II and III dropwise to material I successively under rapid stirring to form a catalyst slurry, and stirring and aging at 100° C. for 3 hours;

[0089] e) the slurry is spray-dried to obtain the catalyst precursor 1;

[0090] f) pre-calcining the catalyst prec...

Embodiment 2

[0096] 1. Catalyst preparation

[0097] a) 500 grams of ammonium heptamolybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O and 13.3 grams of KOH were added to 500 grams of warm water at 70°C, and stirred to make them all dissolve to form material I;

[0098] b) Add 123.5 grams of ammonium metavanadate NH to 250 grams of water 4 VO 3 forming material II;

[0099] c) 52.1 grams of antimony trioxide Sb 2 o 3 Add 100 grams of 70 ℃ hot water, stir and dissolve, then add 171 grams of copper nitrate Cu(NO 3 ) 2 ·3H 2 O, 82 grams of lanthanum nitrate La (NO 3 ) 2 .6H 2 O, 82 grams of praseodymium nitrate Pr (NO 3 ) 2 .6H 2 O and 95.3 grams of ammonium tungstate stirring and dissolving make material III;

[0100] d) adding materials II and III dropwise to material I successively under rapid stirring to form a catalyst slurry, and stirring and aging at 100° C. for 3 hours;

[0101] e) the slurry is spray-dried to obtain the catalyst precursor 1;

[0102] f) pre-calcining the catalys...

Embodiment 3

[0108] 1. Catalyst preparation

[0109] a) 500 grams of ammonium heptamolybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O and 13.3 grams of KOH were added to 500 grams of warm water at 70°C, and stirred to make them all dissolve to form material I;

[0110] b) Add 123.5 grams of ammonium metavanadate NH to 250 grams of water 4 VO 3 forming material II;

[0111] c) 52.1 grams of antimony trioxide Sb 2 o 3 Add 100 grams of 70 ℃ hot water, stir and dissolve, then add 171 grams of copper nitrate Cu(NO 3 ) 2 ·3H 2 O, 82 grams of praseodymium nitrate Pr (NO 3 ) 2 .6H 2 O, 82 grams of cerium nitrate Ce (NO 3 ) 2 .6H 2 O and 95.3 grams of ammonium tungstate stirring and dissolving make material III;

[0112] d) adding materials II and III dropwise to material I successively under rapid stirring to form a catalyst slurry, and stirring and aging at 100° C. for 3 hours;

[0113] e) the slurry is spray-dried to obtain the catalyst precursor 1;

[0114] f) pre-calcining the catalyst pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com